About ASIATOOLS

Founded in 2012, our company is a leading Chinese manufacturer specializing in high-end CNC machine tools and critical functional components. As a significant production and sales base for high-end CNC machine tools in China, it has established sales and after-sales service networks across various regions nationwide. Our company is dedicated to providing global clients with high-quality, efficient, and reliable machine tools and services. It consistently prioritizes customer satisfaction as the benchmark for service quality.

Overview

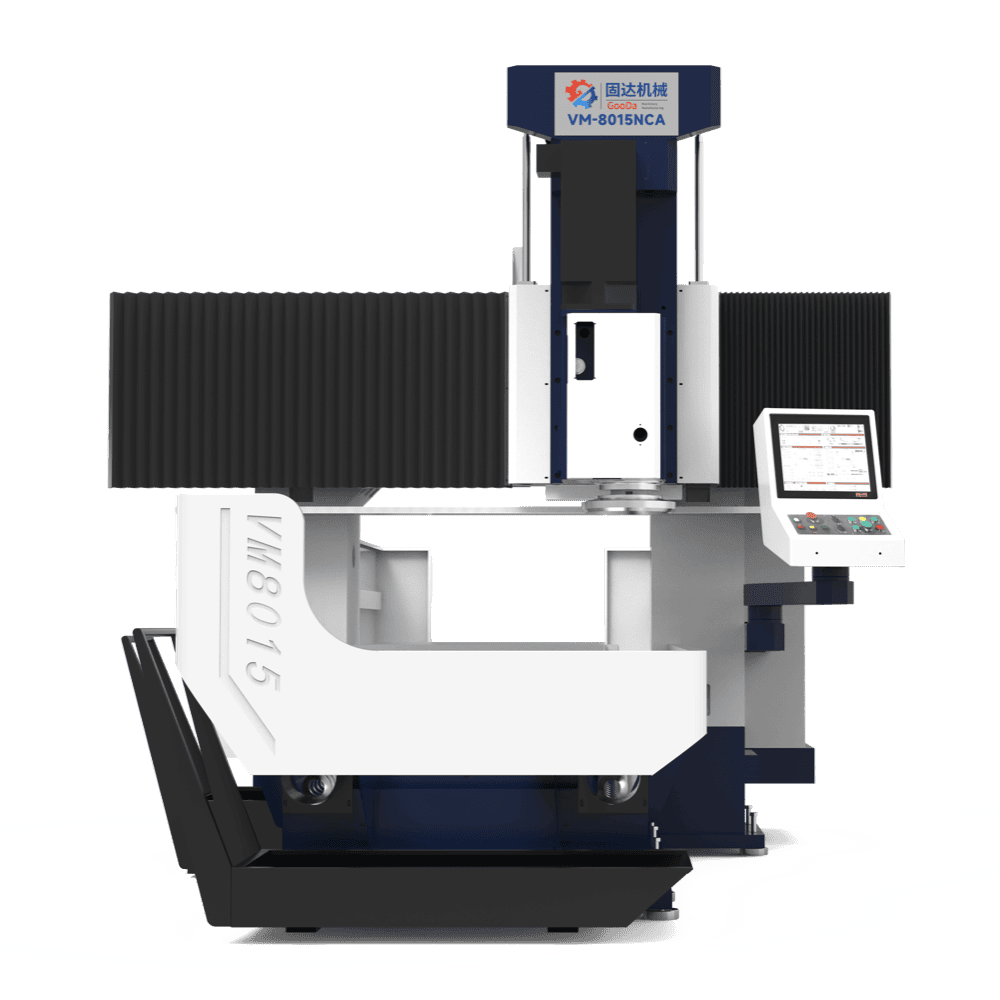

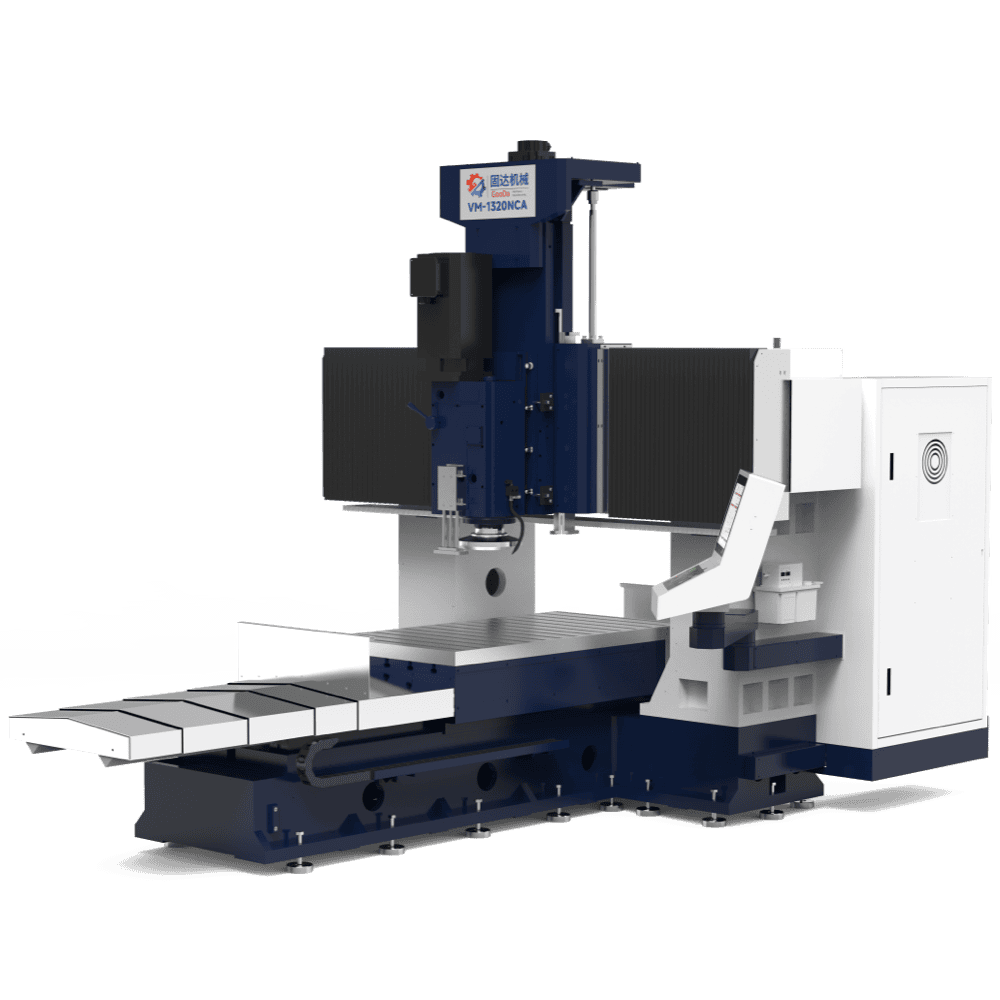

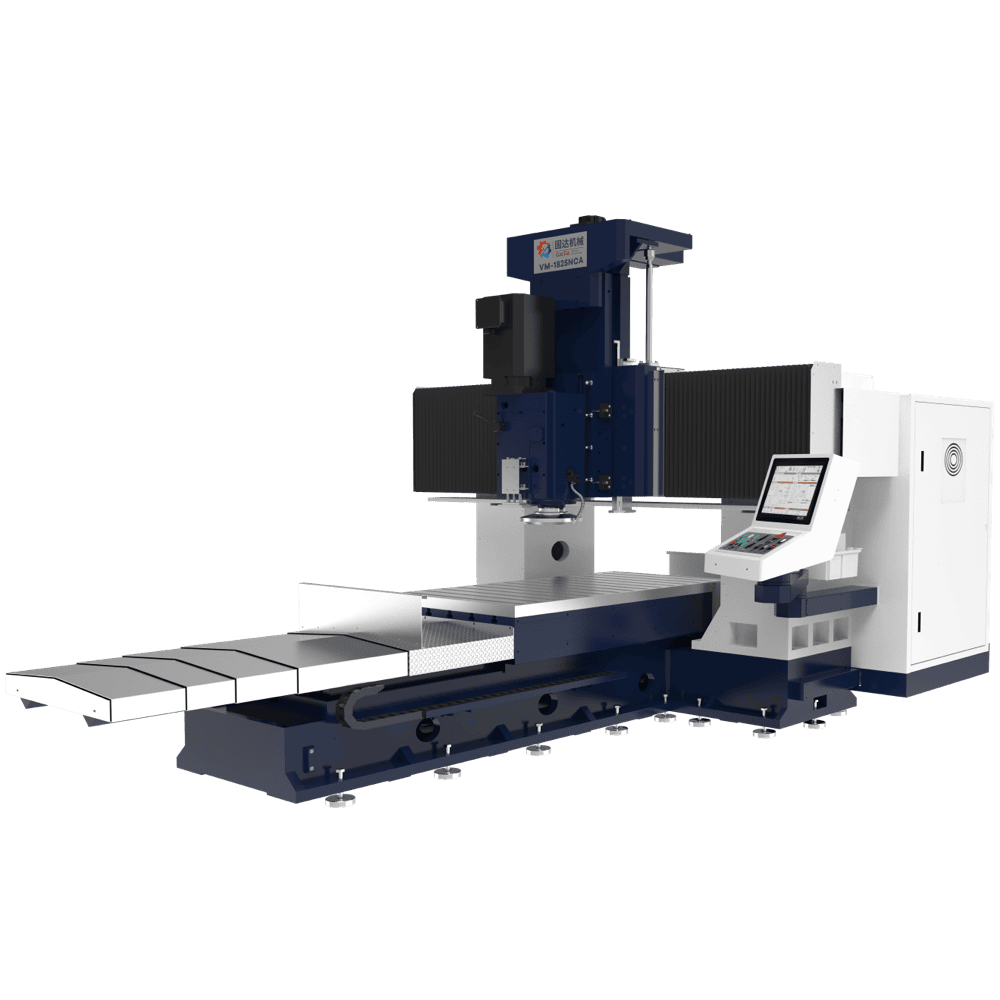

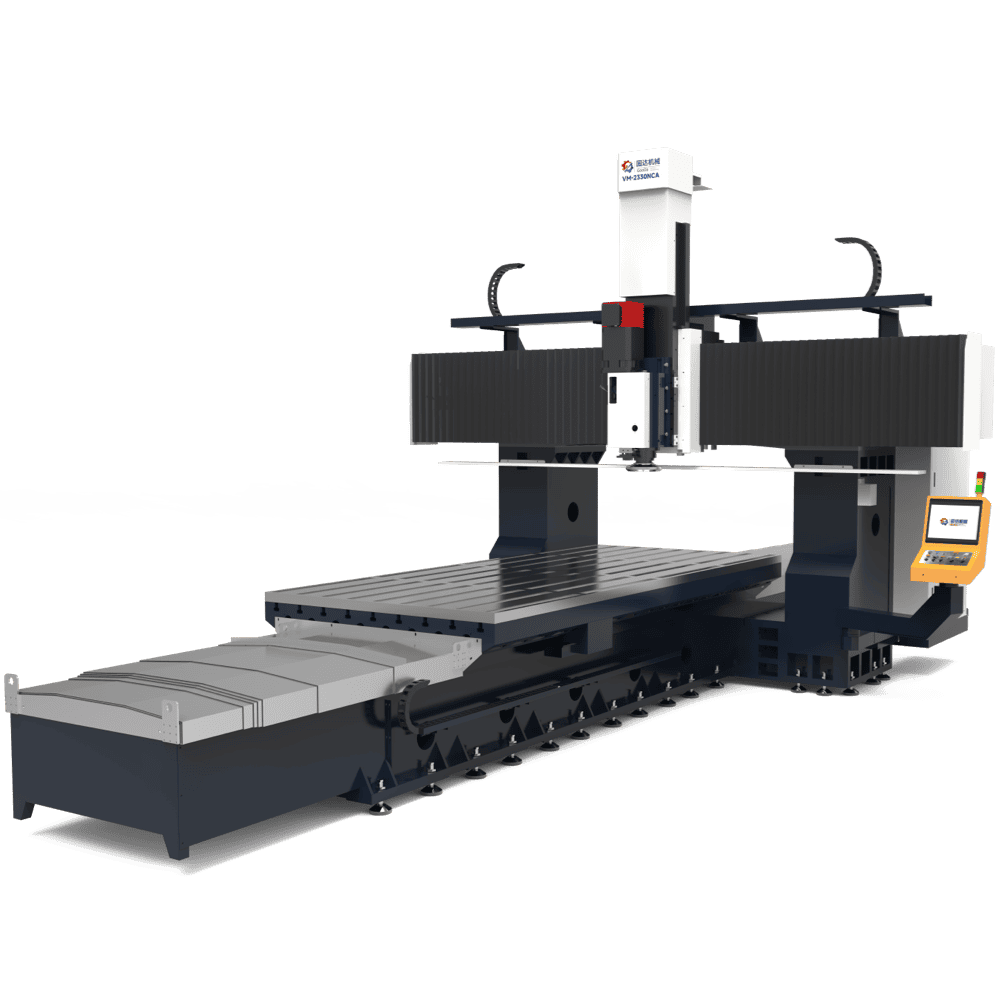

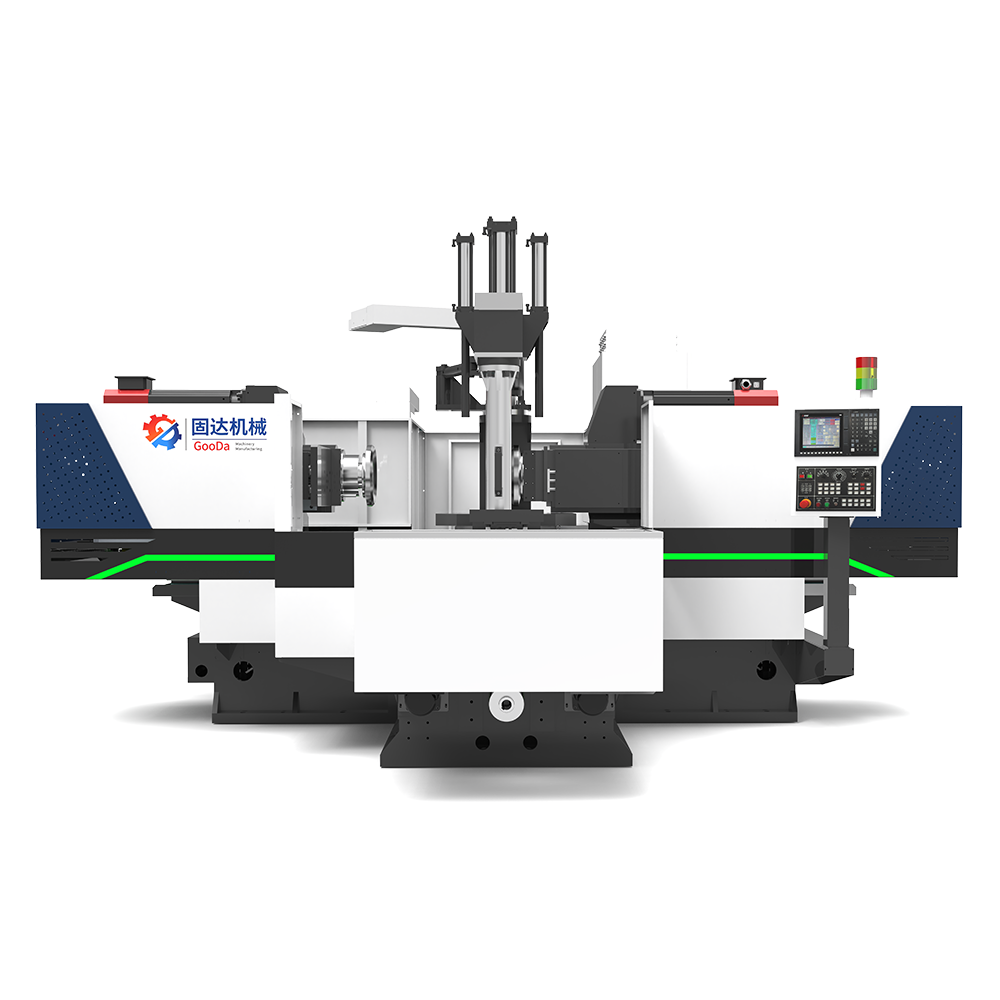

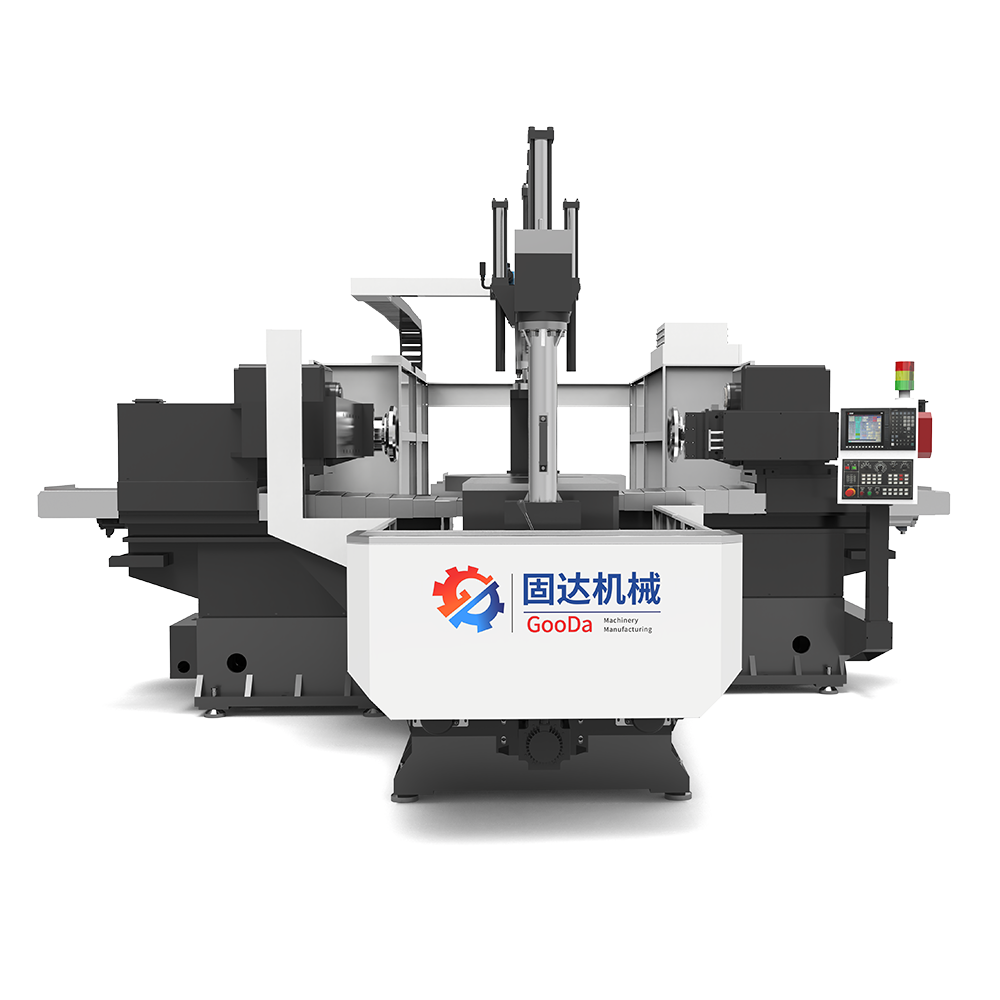

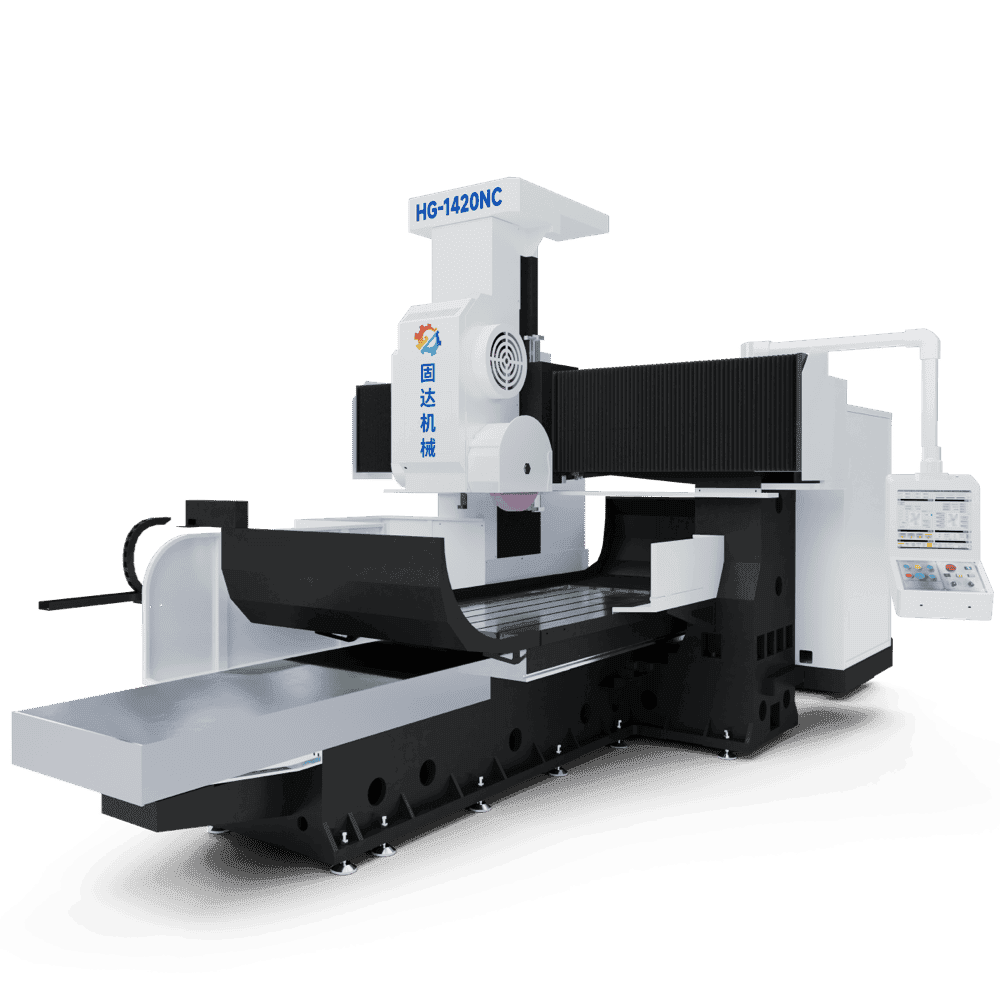

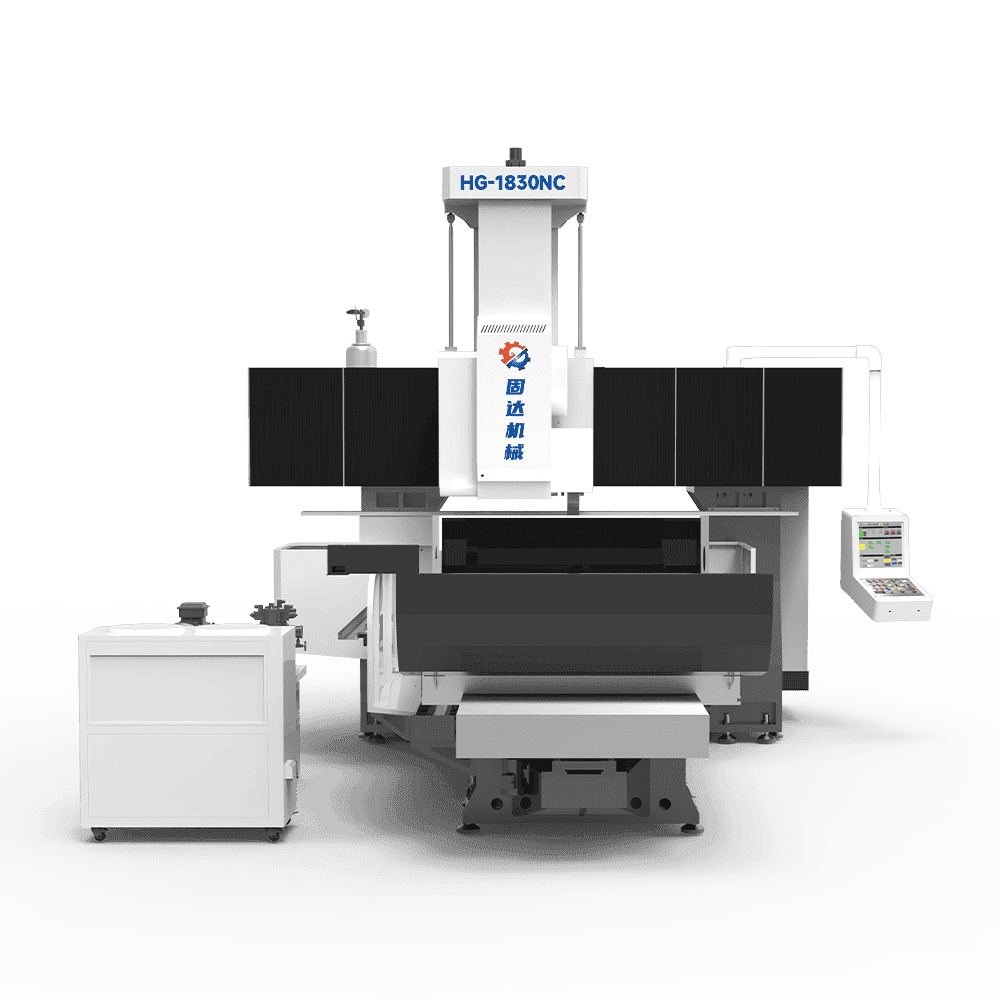

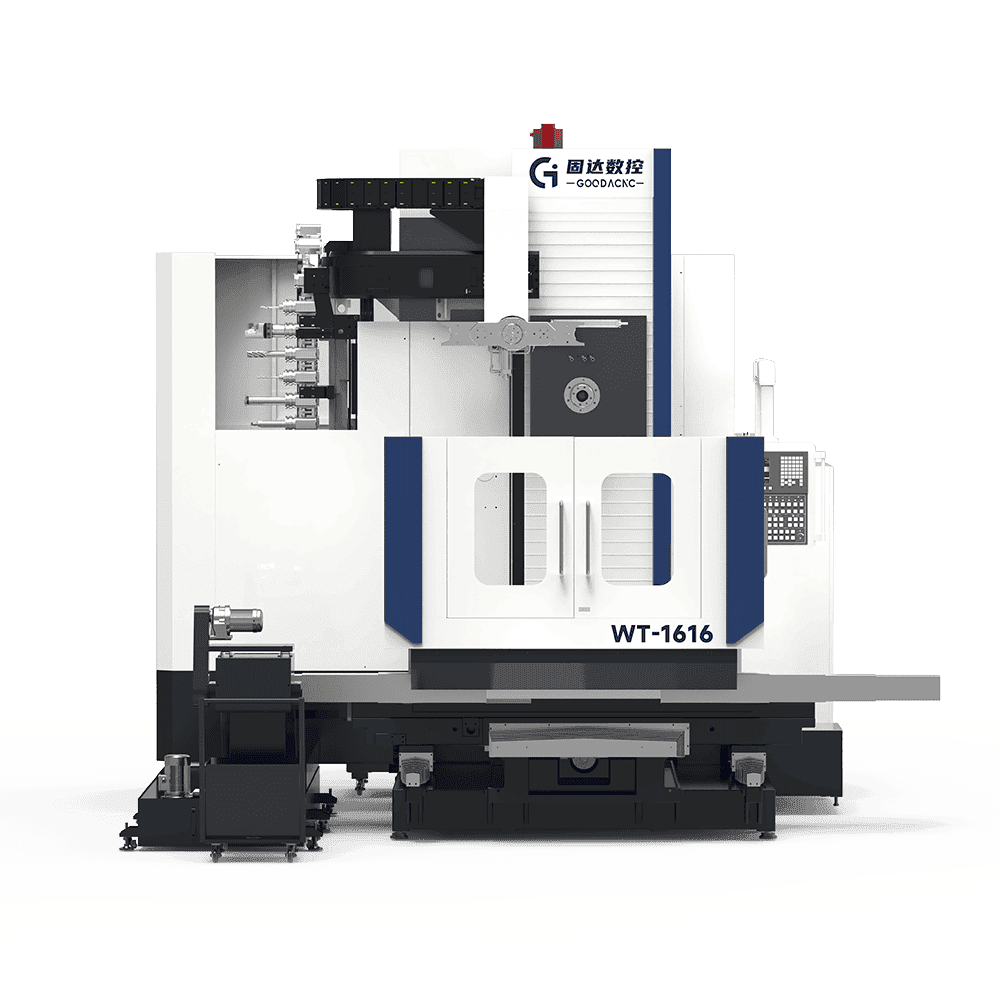

5 Axis CNC Machining Center - 5 Axis CNC Machining Center

Superior Qualities

Efficient, Reliable,Energy-efficient,Your Optimal Choice.

HOW WE HELP

HOW WE HELP

We cordially invite users to contact us at your convenience. Rest assured, we are committed to furnishing customized solutions to meet your specific requirements.

Get a QuoteCNC Machines: info you may interest

-

Q: What is a CNC milling machine?

A: A CNC milling machine is a computer-controlled machine that uses a rotating cutting tool to precisely remove material from a workpiece, creating a finished part based on a digital design, with 'CNC' stands for 'Computer Numerical Control' which governs the machine's movements and cutting actions with high accuracy; essentially, it's a milling machine operated by a computer program to create complex shapes with minimal human intervention.

-

Q: What is the working principle of a CNC milling machine?

A: In a CNC milling machine, rotating cutting tools move relative to the workpiece to remove material. The cutting tool (milling tool) is fixed on a spindle that can rotate. The rotation and movement of the spindle give CNC milling machines the ability to perform three or more axes milling operations.

-

Q: What is the difference between CNC turning and milling?

A: The key difference between CNC turning and milling is that in turning, the workpiece rotates while the cutting tool stays stationary, while in milling, the workpiece remains fixed and the cutting tool moves around it, allowing for more complex shapes to be created on the workpiece with milling compared to the primarily cylindrical shapes produced by turning; essentially, the part that moves is the key distinction between the two processes.

-

Q: What is the difference between a horizontal and vertical machining center?

A: While vertical machines excel at handling tall or deep workpieces, horizontal machines provide better support for heavy parts and allow for more efficient chip evacuation during cutting operations.