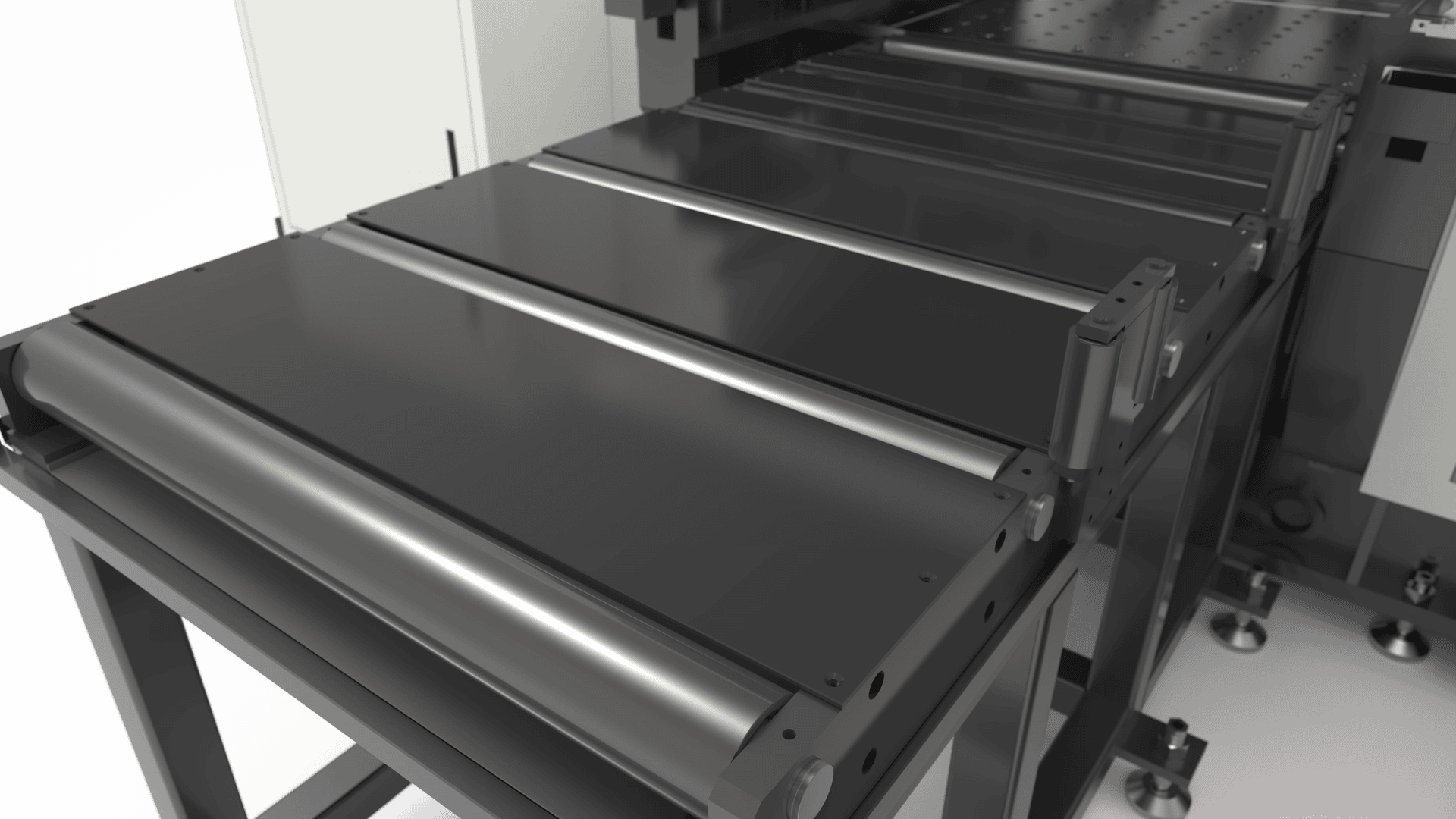

Automatic feeding device

Servo motor drive screw drives feeding jaw feedingpositioning accuracy High, single feeding length of600mm, can be recycled multiple times.

Suitable for high-strength structural steel,stable performance and precision.Workpiece width: 100-850mm.Workpiece thickness: 20-100mm. SAW-850 numerical control high-speed circular saw using carbide saw blade cutting, suitable for high-strength structural steel, tool steel,and alloy steel.For the sawing of wear-resistant steel and other metal sheets, the sawing finish is less than or equal to Ra6,3 um, which can be subversive to achieve "saw-miling" The machine has reasonable structure,stable performance and high precision.

Automatic feeding device

Servo motor drive screw drives feeding jaw feedingpositioning accuracy High, single feeding length of600mm, can be recycled multiple times.

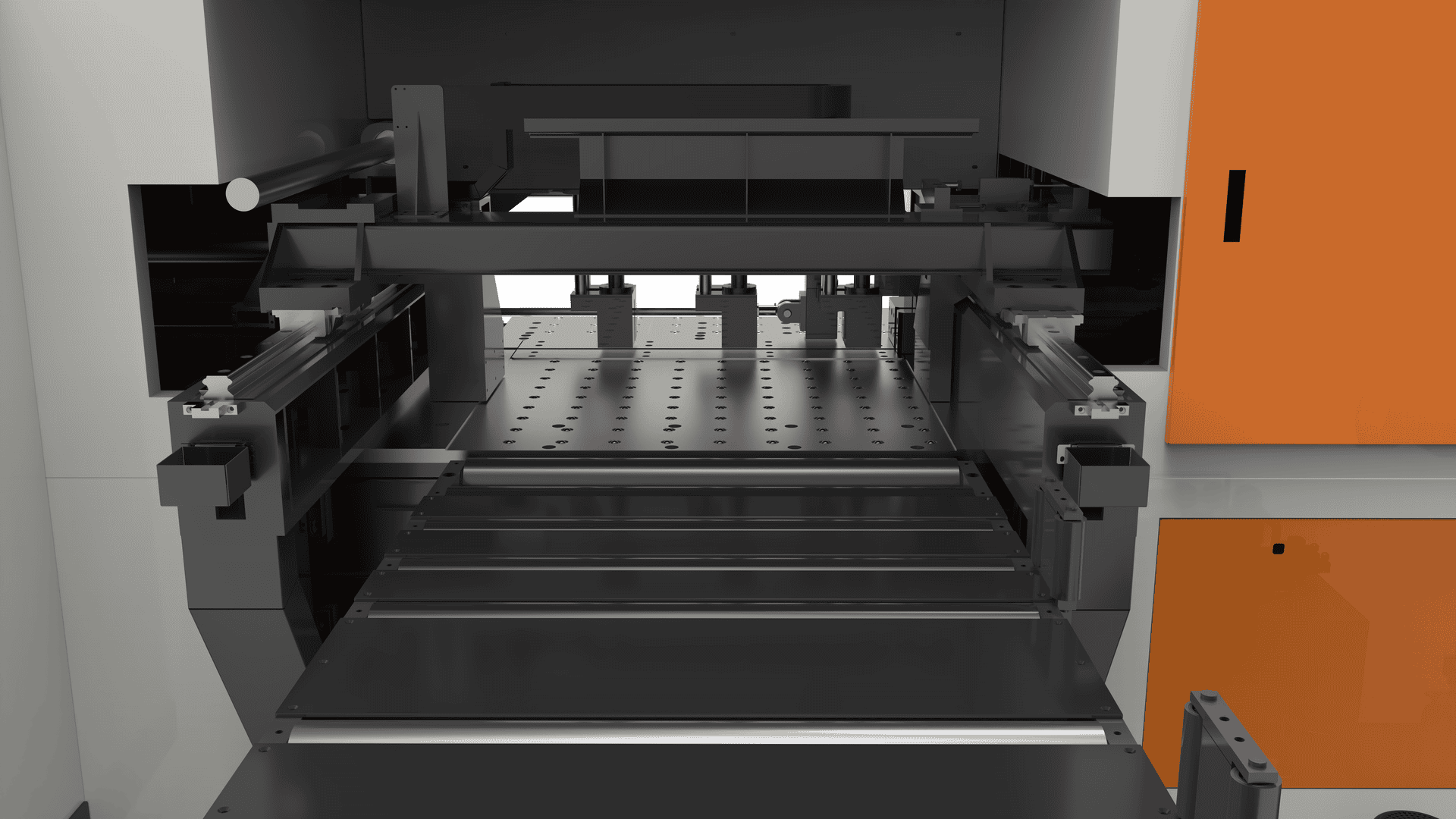

Hydraulic clamping

It is clamped by the upper pressure side top, which is firm and reliable to ensure the sawing accuracy.

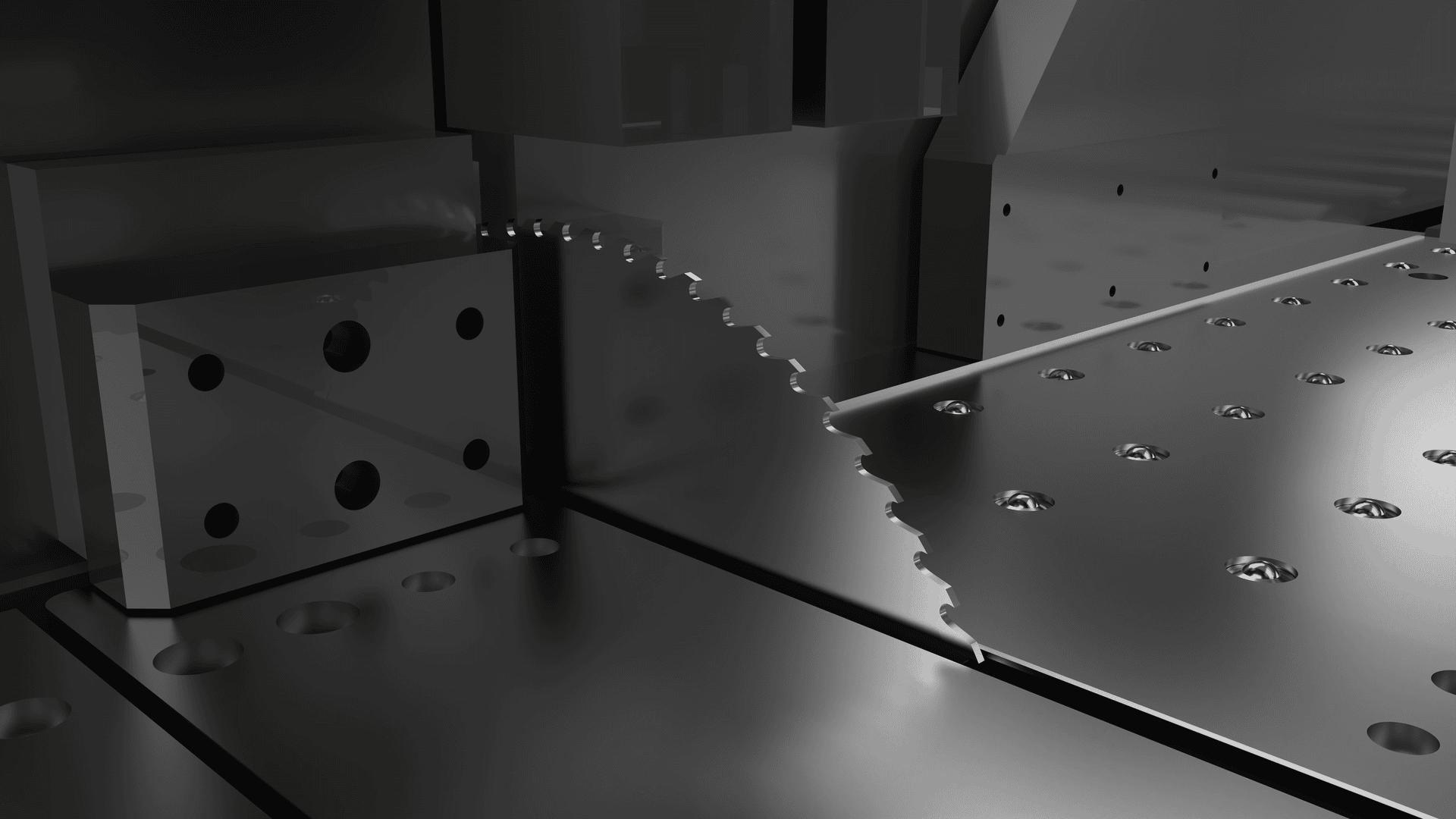

Alloy saw blade cutting

Carbide saw blades are suitable for high-hardness materials, achieving high efficiency, high precision,High surface roughness machining to achieve "sawmilling" effect.

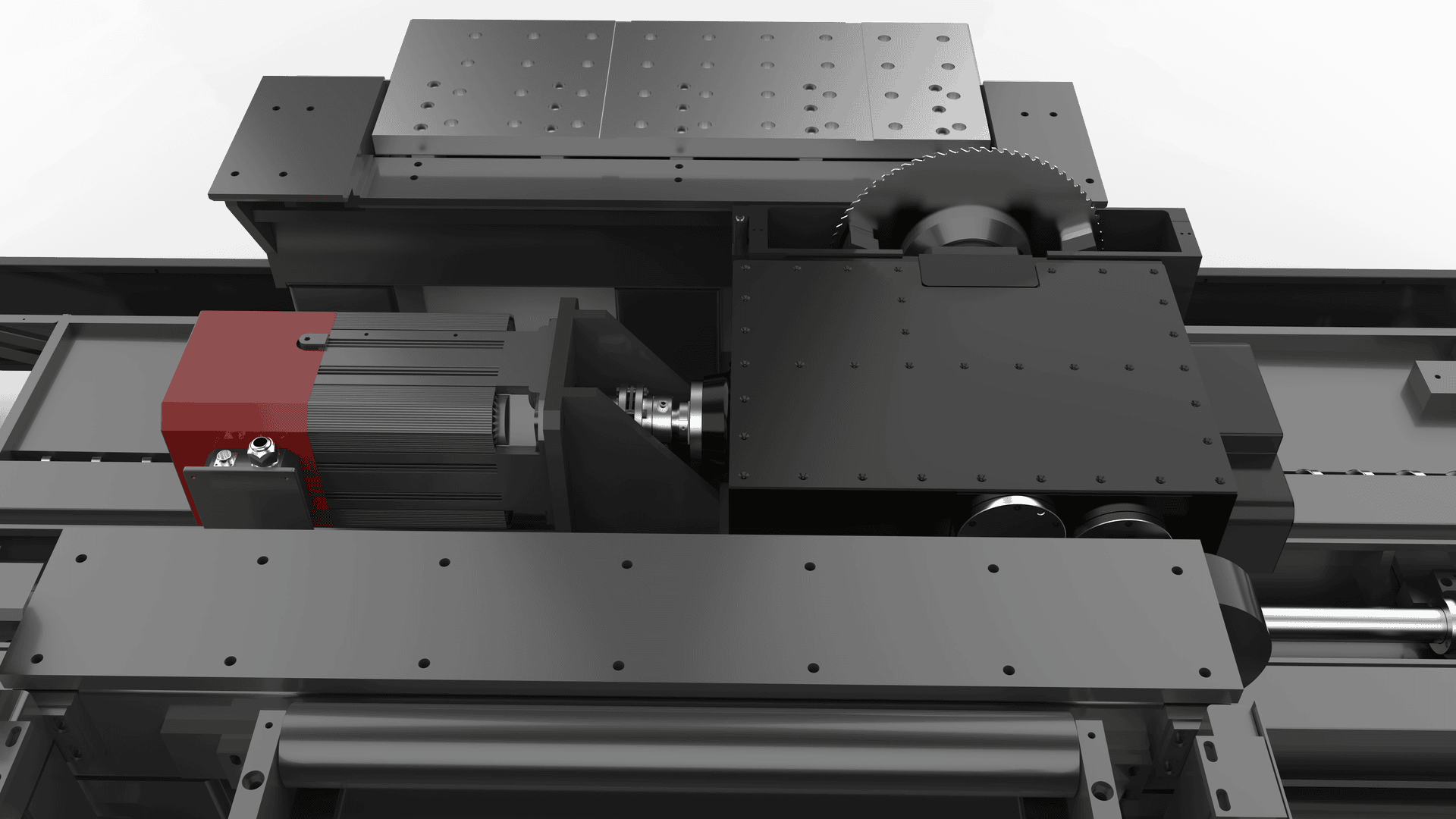

Transmission system

Gear-type headstock structure, with high-power spindle motor to ensure torque The output is strong and stable.

| Items | Value | Unit | |

| Main saw blade | Spindle speed | 50-150 | rpm |

| Spindle motor power | 22 | KW | |

| Saw blade diameter | D460 | mm | |

| Sawing capacity | Sawing sheet width | 100-850 | mm |

| Sawn sheet thickness | 20-100 | mm | |

| Sawing length | ≥20 | mm | |

| Raw material length | ≤3000 | mm | |

| Saw carriage | Feed motor power | 3 | KW |

| Rapid feed rate | 6000 | mm/min | |

| Cutting speed | 100-400 | mm/min | |

| Material feeding | Feeding motor power | 1.5 | kw |

| Feeding method | Cycle multiple feeds | mm / min | |

| Feeder positioning accuracy | 0.05 | mm / 300mm | |

| Sawing accuracy | Roughness of sawing surface | 3.2 | ㎛ |

| Verticality of sawing face | 0.2/100 | mm | |

| Straightness of sawing face | 0.1/850 | mm | |

| Sawing dimensional tolerance | ±0.15 | mm | |

| Clamping method | Clamping method | Vertical and horizontal clamping | / |

| Cutting fluid | Cutting fluid | Emulsion | / |

| Chip removal method | Chip removal method | spiral chip removal machine | / |

| Machine size & weight | Machine size | 4250*3470*2150 | mm |

| Machine weight | About9000 | KG | |

Contact us for more information on our Custom Made Machine Tools Solutions for complex workpieces. When you need high rigidity, efficiency and powerful machines,Asiatools Machinery gets you going!

To meet your different processing needs, we provide three widely used systems on the market for you to choose.

FANUC CONTROLLER

Fanuc oi-MF Plus 10.4'' Touch screen control panel Fanuc oi-MF Plus 10.4'' keyboard control panel. The simple and functional panel, the comfortable operational functional keyboard panel. User-friendly interface and Easy conversational operating program.

MITSUBISHI CONTROLLER

Mitsubishi-M80 series 10.4''Touch screen control panel Mitsubishi-E80 series 8.4'' keyboard control panel. The simple and functional panel, the comfortable operational functional keyboard panel. User-friendly interface and Easy conversational operating program.

CHINA CONTROLLER

JK 15'' Touch screen control panle. Easy operating program. Big and simple operating interface as smart phone touchscreen.Our relationship with clients doesn't end with the sale. We offer comprehensive after-sales support that encompasses everything from expert installation services to hands-on training sessions, ensuring your team is fully equipped to operate and maintain our machinery. Our responsive customer service and technical support are always at your disposal, providing solutions and assistance to keep your operations running smoothly