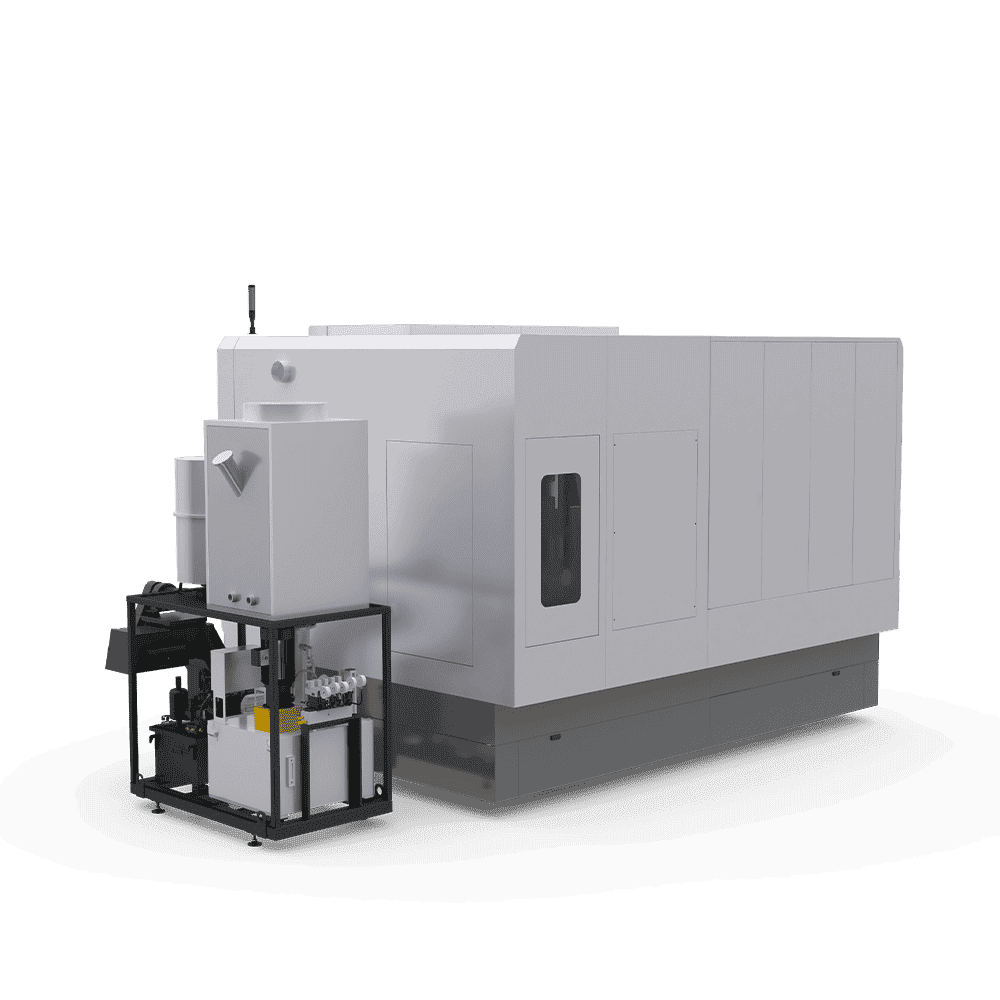

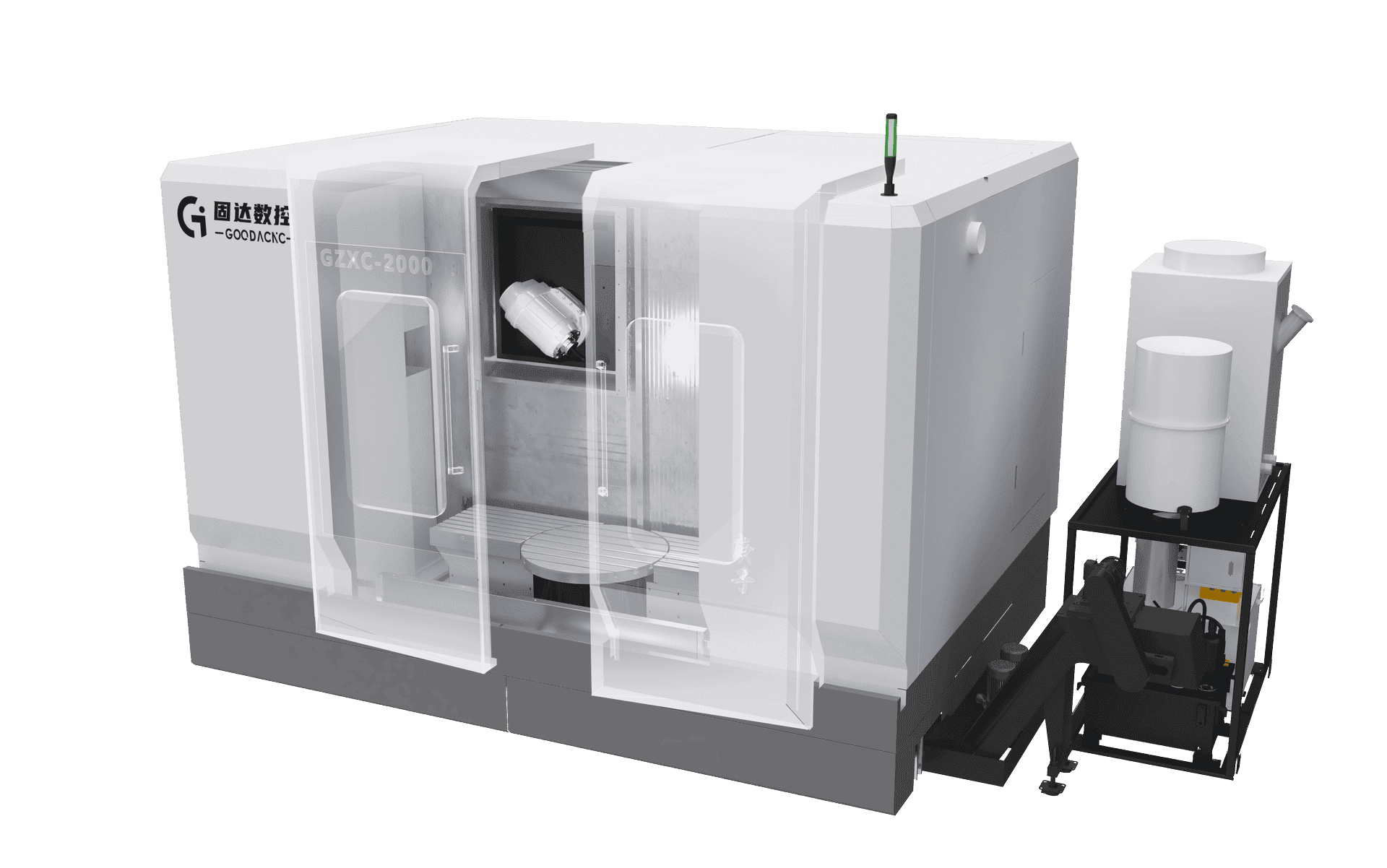

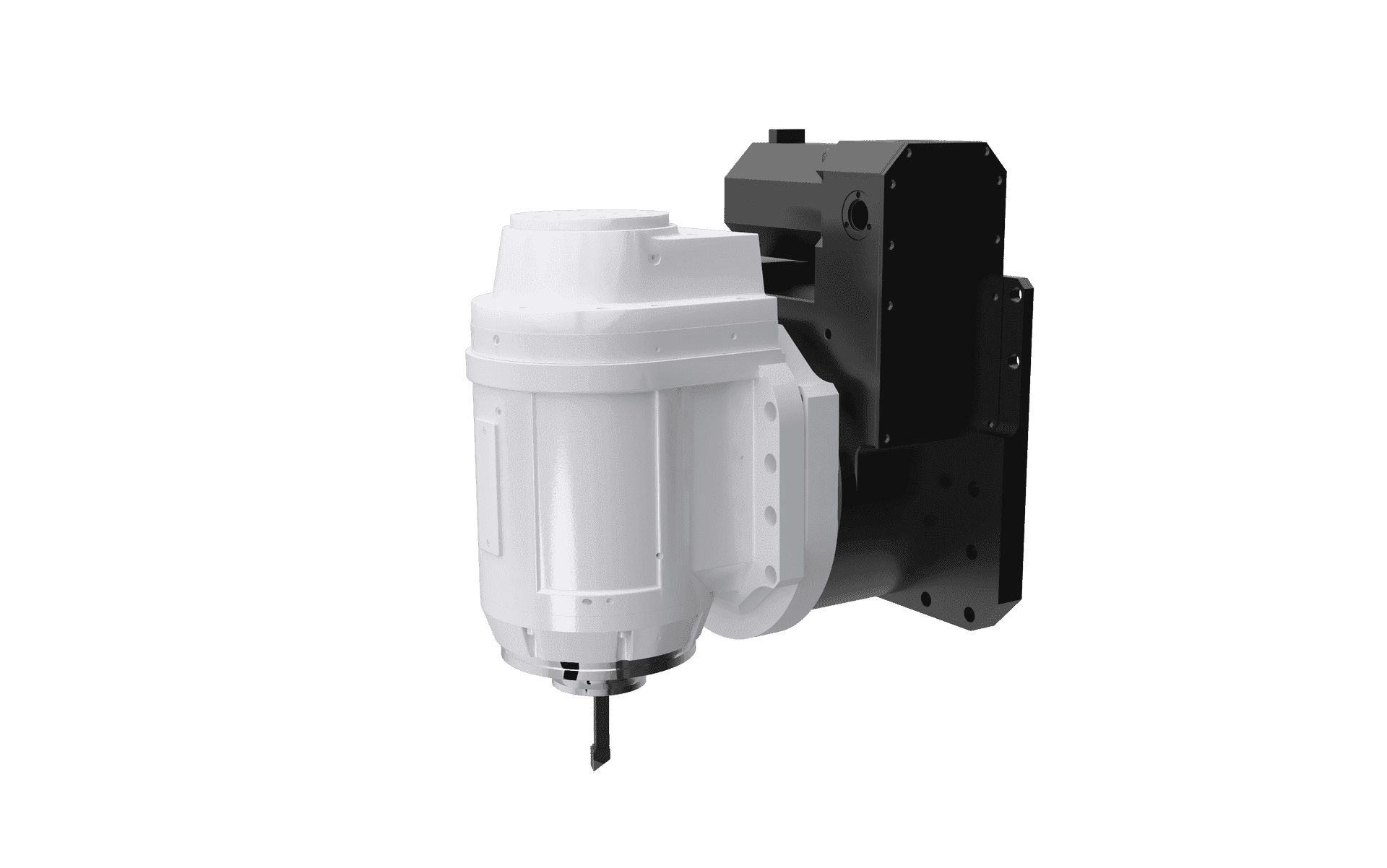

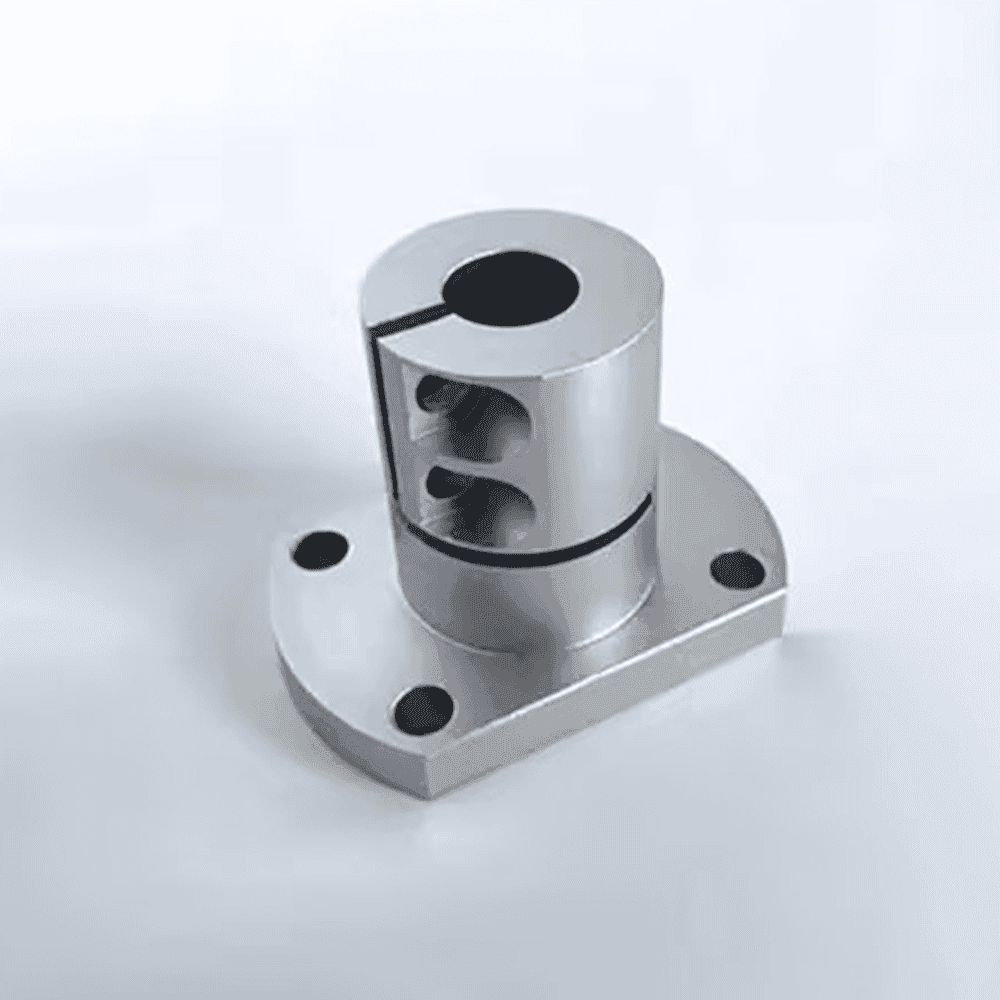

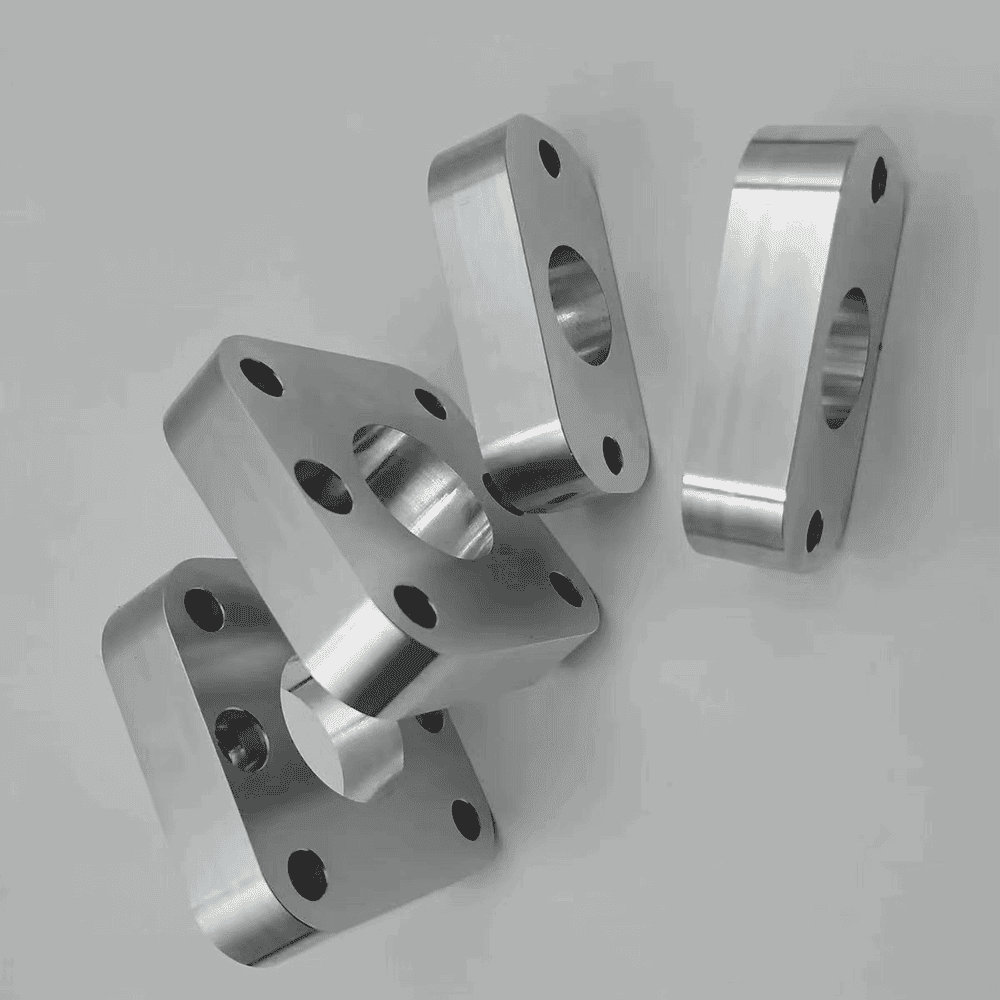

Spindle external coolant system

By circulating cooling water with temperature control in the outer cylinder of the spindle bearing part, it suppresses the deformation of the spindle due to the heat generated when it rotates at a high speed, thereby preventing changes in machining accuracy.