Easy to Assemble

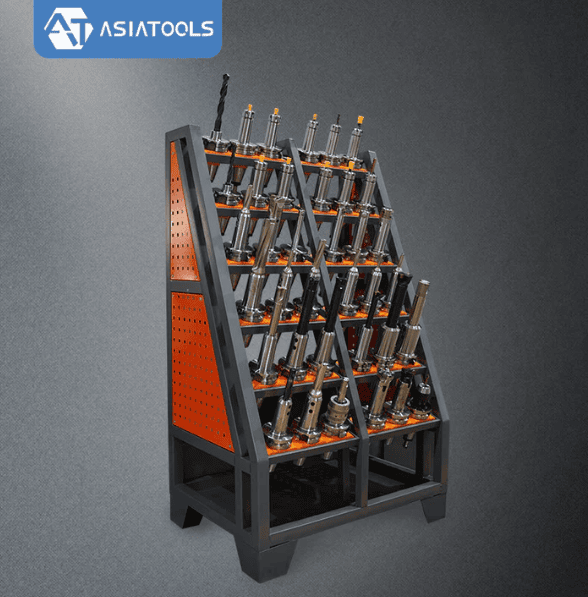

Robust design with premium thick cold-rolled steel square tubing in a solid triangular structure to prevent any tilting of the CNC machine tool holder cabinet during long operation hours.

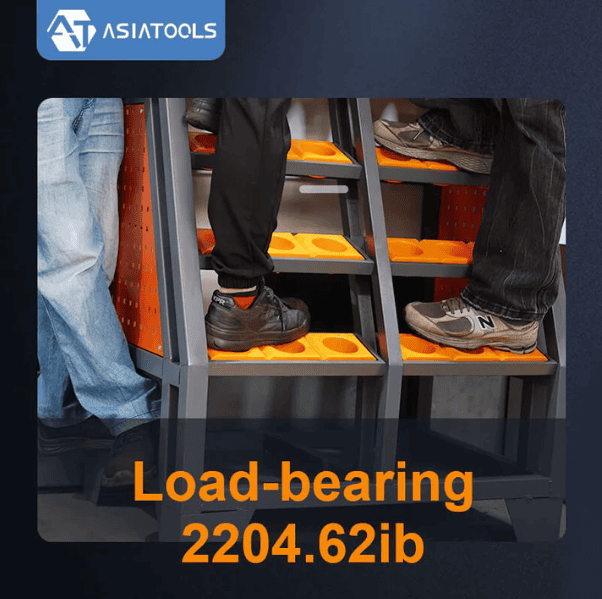

Versatile Tool Storage Solution: compatible with different tool series including HSK, BT, CAT, SK, CAPTO and more. Excellent Weight-Bearing Capability: Built from cold-rolled steel pipes, the triangular structure ensures a load-bearing capacity of up to 1000KG, providing stability and reliability during tool operation. Easy Installation: Tool holders come pre-assembled, simplifying the setup process. Simply follow the installation instructions to set up your components and get started. After-Sales Guarantee: with a packing list and installation instructions, if you have any questions, please contact us in time, and we will offer you solutions within 24 hours.

Easy to Assemble

Robust design with premium thick cold-rolled steel square tubing in a solid triangular structure to prevent any tilting of the CNC machine tool holder cabinet during long operation hours.

Easy to Move

Equipped with wheels are designed for effortless mobility, providing convenient access to your tools wherever you need them. Ideal for professional machinists, shop workers, and manufacturers, these carts accommodate all types of CNC tools, enhancing the efficiency of workshops, factories, and manufacturing processes.

High-quality Material

The knife cover is made of advanced ABS material, offering a cushioning effect that minimizes collisions between the handle and the cover. It is designed to withstand heavy loads and frequent use, making it ideal for secure storage on CNC transfer carts.

Multiple choices

We offer a wide variety of CNC tool carts to suit your needs. Our team will recommend the most suitable tool cart based on your specific requirements, ensuring that you have the perfect solution for your workshop or manufacturing environment.

| Product type | CNC tool cart, CNC tool rack, CNC storage cabinet, clamping tool workbench, workstation, transfer tool cart, CNC tool transport cart, CNC tool compartment cabinet, CNC parts compartment cabinet | |

| Material | High quality cold rolled steel | |

| Back plate material type | Alloy steel | |

| Color | Gray+orange | |

| Model | HSK/BT/CAT/SK/CAPTO | |

| MOQ | 1 set | |

| Applicable machine tools | lathes\CNC machine tools | |

| Packaging dimensions | Carton or wooden frame | |

| Features | Waterproof and corrosion-resistant | |

| Installation type | Floor-standing | |

| Load capacity | Withstands total weights of up to 1000 kg (single layer plate up to 100kg) |

Our commitment to clients extends well beyond the purchase of CNC accessories. We provide comprehensive after-sales support, including expert installation guidance and hands-on training sessions, to ensure your team is fully prepared to use and maintain our products effectively. Our dedicated customer service and technical support teams are always available to assist you, offering solutions and advice to ensure your operations remain efficient and uninterrupted.

Q: What is CNC tooling carts?

A: CNC tool carts are designed to enhance efficiency and organization in machine shops for storing, transporting, and organizing CNC tooling. These carts are typically made from heavy-duty materials to withstand the demanding environment of CNC operations. They often come equipped with features like lockable drawers, pegboards, and various compartments to securely hold tools and accessories, ensuring they are easily accessible and well-protected.

Q: What are CNC tooling carts used for?

A: CNC tooling carts are designed to store, organize, and transport CNC tools efficiently within a workshop or manufacturing environment. They help streamline tool access and improve workflow efficiency.

Q: What types of tools can be stored in CNC tooling carts?

A: These carts can accommodate various types of CNC tool holders, such as CAT, BT, and HSK, depending on the cart design. They are versatile enough to hold different sizes and types of tools.

Q: How do I choose the right CNC tooling cart for my needs?

A: Consider the number of tools you need to store, the type of tool holders you use, and the space available in your workshop. Some carts are designed for specific tool holder types, so ensure compatibility with your tools.

Q: Are CNC tooling carts mobile?

A: Yes, most CNC tooling carts are equipped with wheels for easy mobility, allowing you to move tools to different workstations as needed.

Q: What are the benefits of using CNC tooling carts

A: They provide organized storage, protect tools from damage, reduce setup time, and improve overall efficiency in tool management and accessibility.