Customized Forging Solutions by ASIATOOLS

Strong supply chain resources ensure that ASIATOOLS can provide a complete production line from raw material selection, forging, heat treatment to CNC machining, and all control systems and production links are subject to strict quality inspections.

ASIATOOLS has brought together many forging industry experts and technically trained sales staff. These experts can provide you with on-site forging information. If you have any forging needs, please feel free to contact us.

- Customized Service

- Various Types of Forging Material Available

- 50+ Forging Plants Integration

- Thorough Test Before Delivery

One-Stop Service from

Forging to Finishing

It is easy to do business with ASIATOOLS because we can flexibly customize different forging services

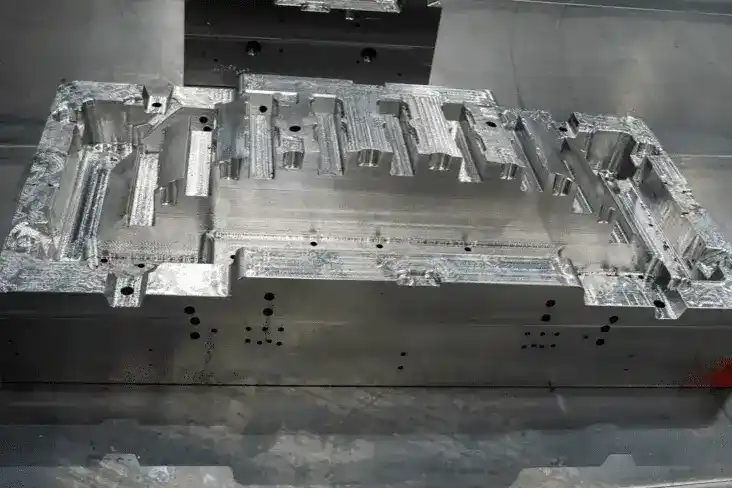

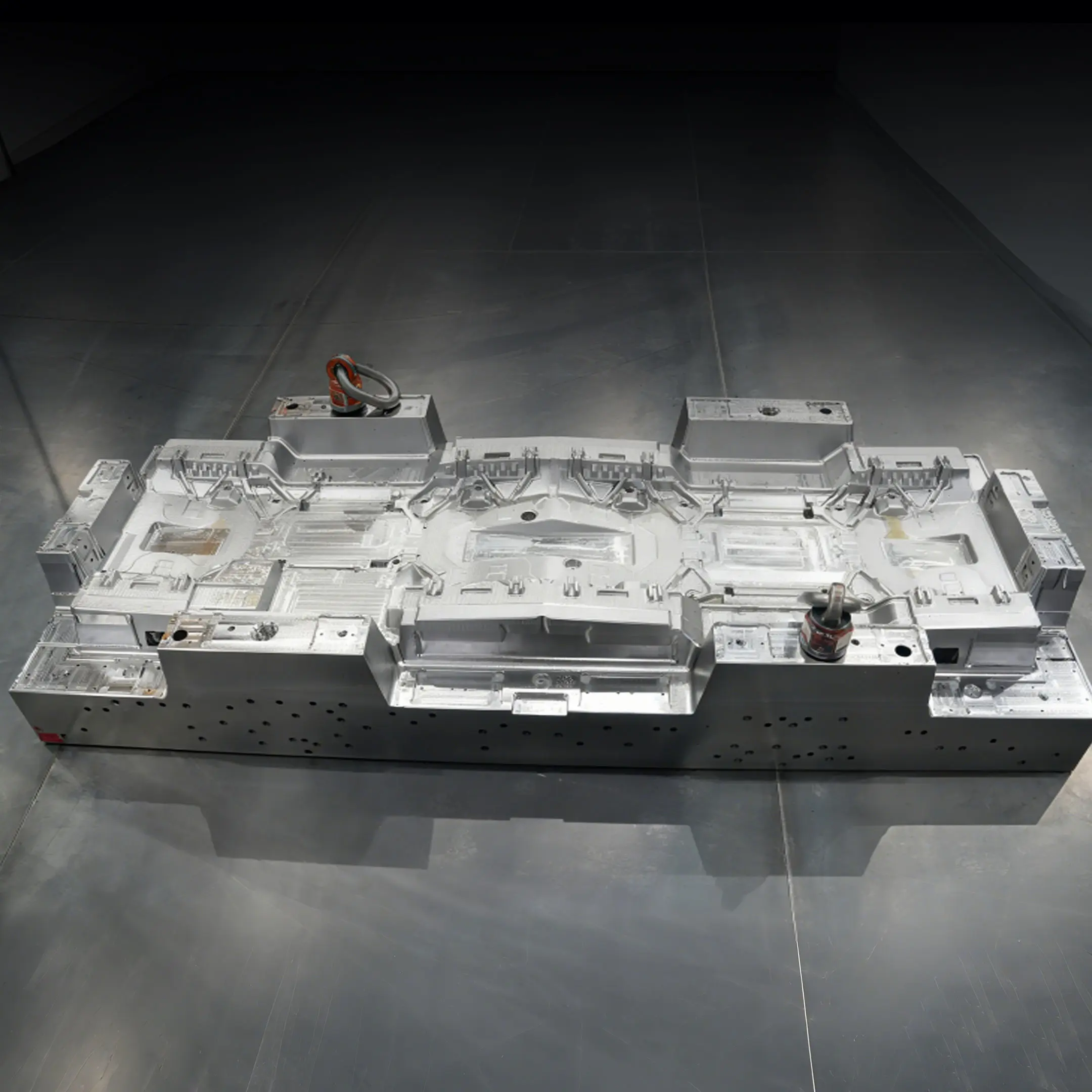

according to your needs. The Following pictures are finished mold steel products we can make.

It is easy to do business with ASIATOOLS because we can flexibly customize different forging services according to your needs. The Following pictures are finished mold steel products we can make.

-

melting

-

-

Forging

-

Heat Treating

-

CNC Milling

-

CNC Boring

-

CNC Machining

-

-

melting

-

-

Forging

-

Heat Treating

-

CNC Milling

-

CNC Boring

-

CNC Machining

-

How We Ensure Your Forging Project Success

At ASIATOOLS, we understand your expectations for the forging projects, and our staff will ensure that your forging project goes smoothly by:

- Expert Forge Design and Engineering Guidance

- Comprehensive Machining Options

- Thorough Metallurgical Review, Non-Destructive Evaluation (NDE), and Destructive Testing

Our Products

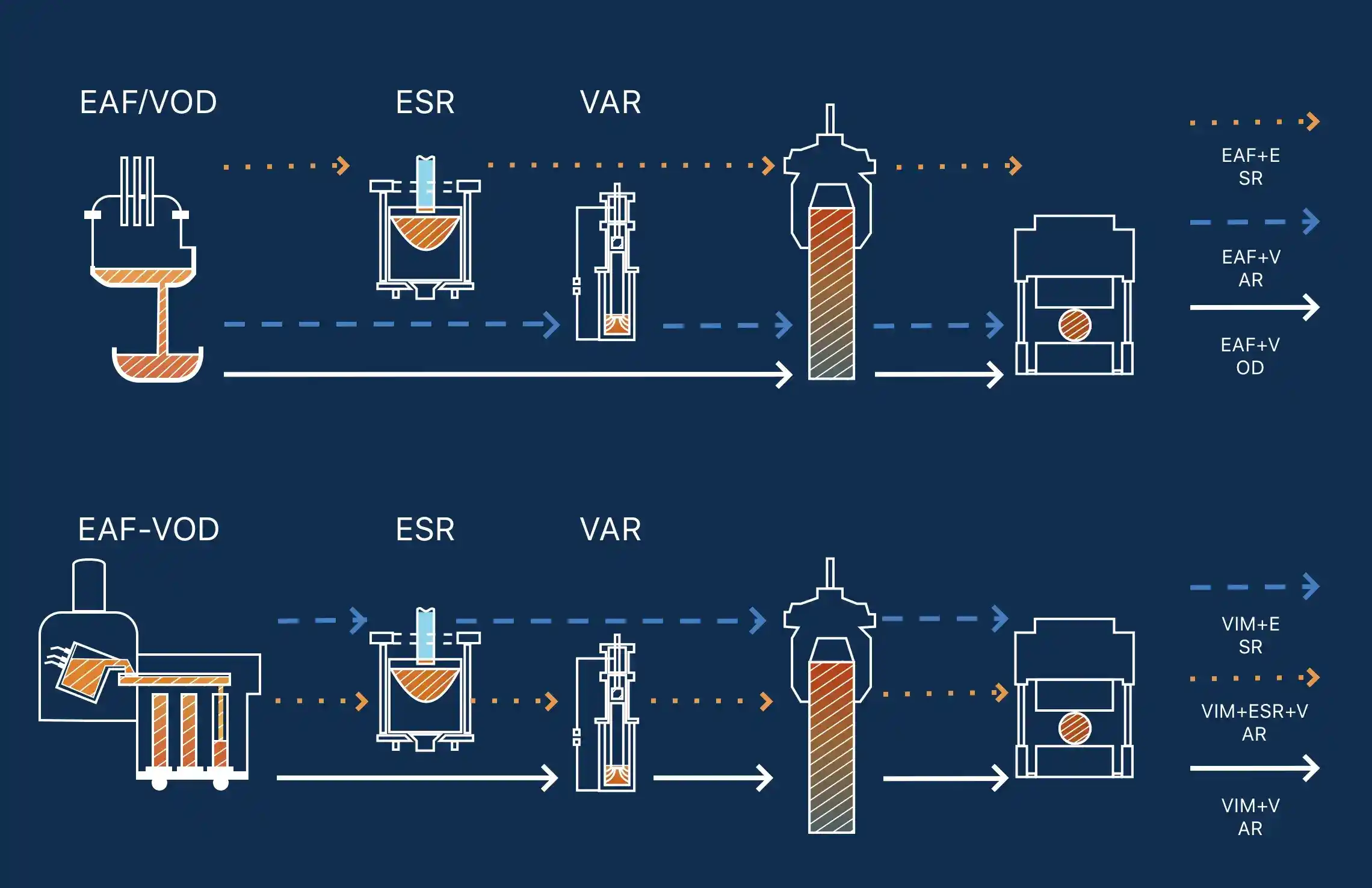

Production Technology

We have a full range of equipment, such as VIM, VAR, ESR, etc.

Common Production Technology:EAF+LF+VOD (Forging + Homogenization treatment + Spheroidizing annealing treatment)

Quality Steel Materials We Offer

We can provide a variety of materials to support your envisioned projects. Steel types include hot work steel, cold work steel, plastic mold steel, etc. Contact our sales expert for more information.

| Category | Compare standards | Hardness | Steel characteristics | Main purpose | ||

| AIS | DIN | JIS | HRC | |||

| Cold working steel | D2 | 1.2379 | SKD11 | 58-63 | Tool steel contains 12% chromium and has rigidity, wear resistance, and strength. | Material dropping, precision punching, punching, cutting, trimming, and cutting. |

| / | / | / | 58-64 | Anti-mixed wear, anti-chipping, good mechanical processing, and WEDM (wire electrical discharge machining). | Material dropping, precision punching, cutting, forming, embossing, cold forging, cold extrusion, wire rolling, deep drawing, and powder compaction. | |

| / | 1.2631 | / | 52-58 | A vacuum oil quenched or gas quenched tool and die steel with good heat treatment dimensional stability, good machining, and grinding performance, excellent toughness and wear resistance comprehensive performance. | It can punch steel plates with a thickness of up to 25 millimeters. It is suitable for precision punching, shearing, stretching forming, hot forming, cold forging, forging dies, rolling rolls, cold extrusion molds with complex geometric shapes, and pipe drawing tools. | |

| Hot work mold steel | H13 | 1.2344 | SKD61 | 40-52 | Expanded fatigue processing of chromium molybdenum vanadium alloy steel with good high-temperature wear resistance, high-level toughness and ductility, and high-temperature strength performance. Good hardenability. | Suitable for aluminum and magnesium die-casting, hot forming, and hot forging molds. |

| H13 | 1.2344 | SKD61 | 44-52 | Meets and exceeds the NADCA207-2011 standard for high-quality die-casting materials. | Suitable for high-pressure die-casting, hot extrusion, pressure forging molds, and plastic molds. | |

| / | / | / | 44-52 | High performance thermal work has excellent resistance to thermal cracking, overall cracking damage, and plastic deformation. | Ideal choice for aluminum, magnesium die-casting, hot forming, hot forging, and aluminum extrusion. | |

| / | / | / | 44-52 | Compared to H13 material, it has better temper resistance and higher temperature corrosion. | Tools used for hot forging and extrusion. | |

| Plastic mold steel | (P20) | 1.2738 | / | 36-40 | Pre-hardened plastic mold wind steel has excellent polishing performance. | Suitable for blow molding or extrusion molds, blow molding molds, mechanical components, structural components, and shafts for thermoplastic materials. |

| / | / | / | 38-42 | Pre-hardened mold steel has excellent toughness, processability, and polishing performance. | Used for injection molds (such as packaging containers, automotive interior parts, mirrors, panels, and home appliance handles), forging and die-casting molds, wooden frame frames, trimming molds, heat flow diversion pipes, and structural components. | |

| / | / | / | 38-42 | Pre-hardened mold steel has excellent toughness, processability, and polishing performance. | Mainly used in the preparation of molds for transparent, high gloss, or textured plastic products, especially suitable for the automotive industry, white goods, packaging, and electronics industries. | |

| 420 | 1.2083 | SUS420J2 | 44-52 | This is corrosion-resistant mold steel with good corrosiveness; High wear resistance performance; and Good polishing performance. | Applied to mold inserts; Small and medium-sized mold cavities and cores, used for injection molding materials containing corrosive materials (such as PVC) and abrasive additives: small and medium-sized components in long-life molds: molds that work and store in humid environments. | |

| 420 | / | / | 44-52 | Plastic mold stainless steel with unique properties such as toughness, corrosion resistance, and hardenability. | Suitable for various plastic molds, especially large molds with zero tolerance for corrosion and high requirements for product surface smoothness in the production process. | |

| H11 | 1.2343 | SKD6 | 46-52 | High resistance to thermal shock and fatigue, excellent high-temperature strength, good dimensional stability during the quenching process, and superior quenching characteristics. | Suitable for applications that require high toughness, such as die-casting or forging. | |

| / | / | / | 55-58 | Plastic mold stainless steel with excellent toughness, polishing performance, machining performance, corrosion resistance, and wear resistance. | Suitable for long-term production of reinforced plastic molds, compression molding molds, and corrosion-resistant plastic molds. It is also suitable for manufacturing complex molds and molds that require a high gloss surface finish. | |

| 420 | / | / | 36-40 | Corrosion-resistant pre-hardened mold steel. It has good machinability, toughness, and polishing performance. | Suitable for injection and blow molding of corrosive plastics. Plastic molding, PET bottle molding, and structural components for components with high surface smoothness, such as LED (Light Emitting Diode)/LCD (Liquid Crystal Display) baffles and casings. | |

| / | / | / | 52-58 | High hardness and excellent toughness. ESR steel has excellent polishing performance. Suitable for coating and nitriding treatment. | Suitable for reinforced plastic molds with high wear resistance. Suitable for heavy-duty material dropping, powder unpressurized, and warm forging. | |

| / | / | / | 60 | Powder mold steel contains high nitrogen and unique properties such as hardness, wear resistance, ductility, and corrosion resistance. | Plastic mold components, manual cutting tools, cutting tools and parts in food processing, sliding and rolling wear parts in engineering applications that require high corrosion resistance, friction corrosion resistance, and/or demolding performance. | |

CNC Machining by Our Machines

With our CNC machines, we can help you process your steel according to your requirements.

-

What is steel forging?

Steel forging is a process in manufacturing where metal is heated and shaped by applying compressive forces using tools like hammers or dies. This process involves the plastic deformation of the metal.

-

What types of steel forgings exist?

There are several types of steel forgings, including open die, closed die, and rolled ring forgings. Each type is suitable for different applications and can accommodate various sizes.

-

There are several types of steel forgings, including open die, closed die, and rolled ring forgings. Each type is suitable for different applications and can accommodate various sizes.

Steel forgings are made from different steel grades, each offering unique properties for specific applications. These grades include carbon steel, alloy steel, stainless steel, and tool steel.

-

Why choose forging over casting?

Forging is often preferred over casting because it typically results in parts that are stronger and more reliable. This process enhances the metal's grain structure and mechanical properties, making the parts better able to withstand stress and fatigue.

-

In which industries are forged parts used?

Forged parts find applications in numerous industries such as automotive, aerospace, oil and gas, construction, and agriculture, thanks to their strength and durability.

-

What advantages does forging offer?

Forging provides several advantages, including enhanced structural integrity, increased strength, superior fatigue resistance, and cost-effectiveness for high-volume production.