High quality castings

The rigidity of the gantry structure with square columns enables it to withstand loads in multiple directions and torsion, maintaining high precision while heavy cutting.

This machine has been awarded a utility model patent with excellent performance and high cost-effectiveness. The compact layout, aesthetically pleasing appearance, advanced linear motion systems, frequency conversion technology, and CNC system, deliver users high efficiency and reliability. It's suitable for metal-cutting industries involving mold steel, aluminum, and mold processing.

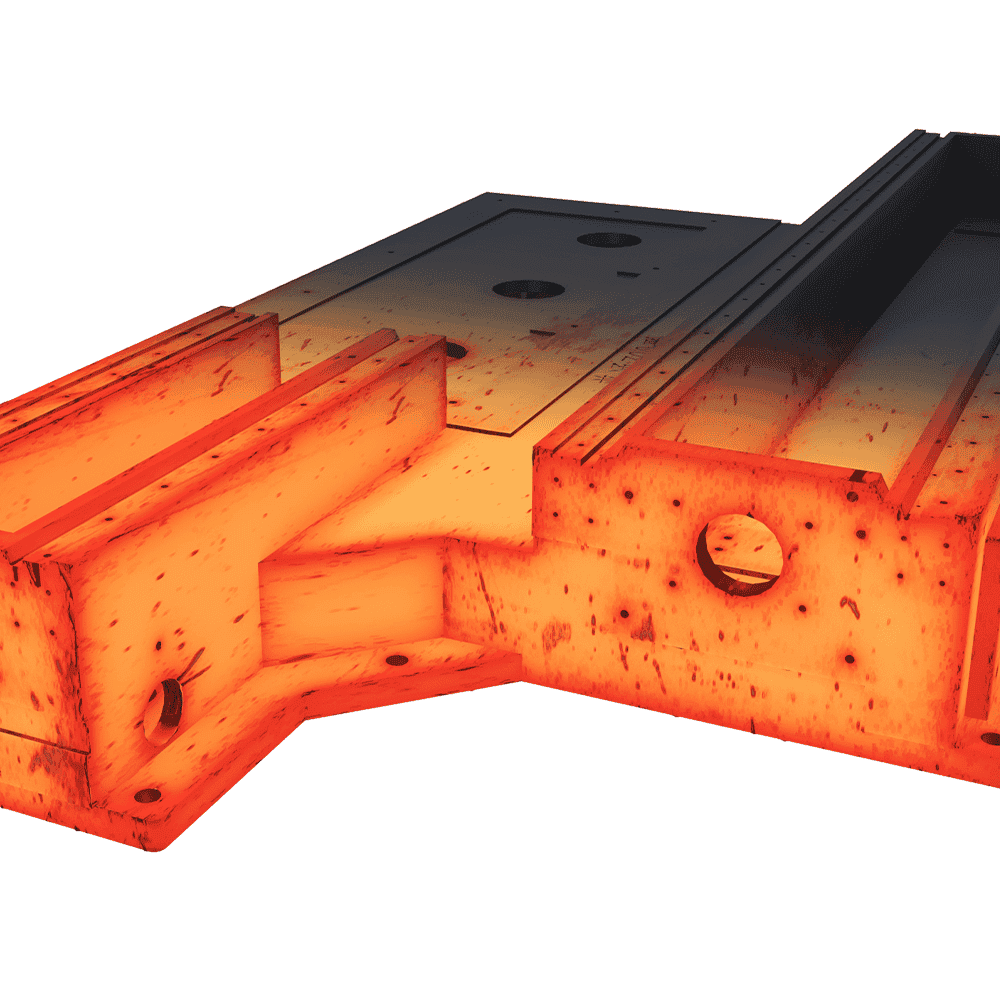

High quality castings

The rigidity of the gantry structure with square columns enables it to withstand loads in multiple directions and torsion, maintaining high precision while heavy cutting.

Electrical control system

Integration of the top beam and crossbeam achieves a robust construction, ensuring stable machining quality over the long term.

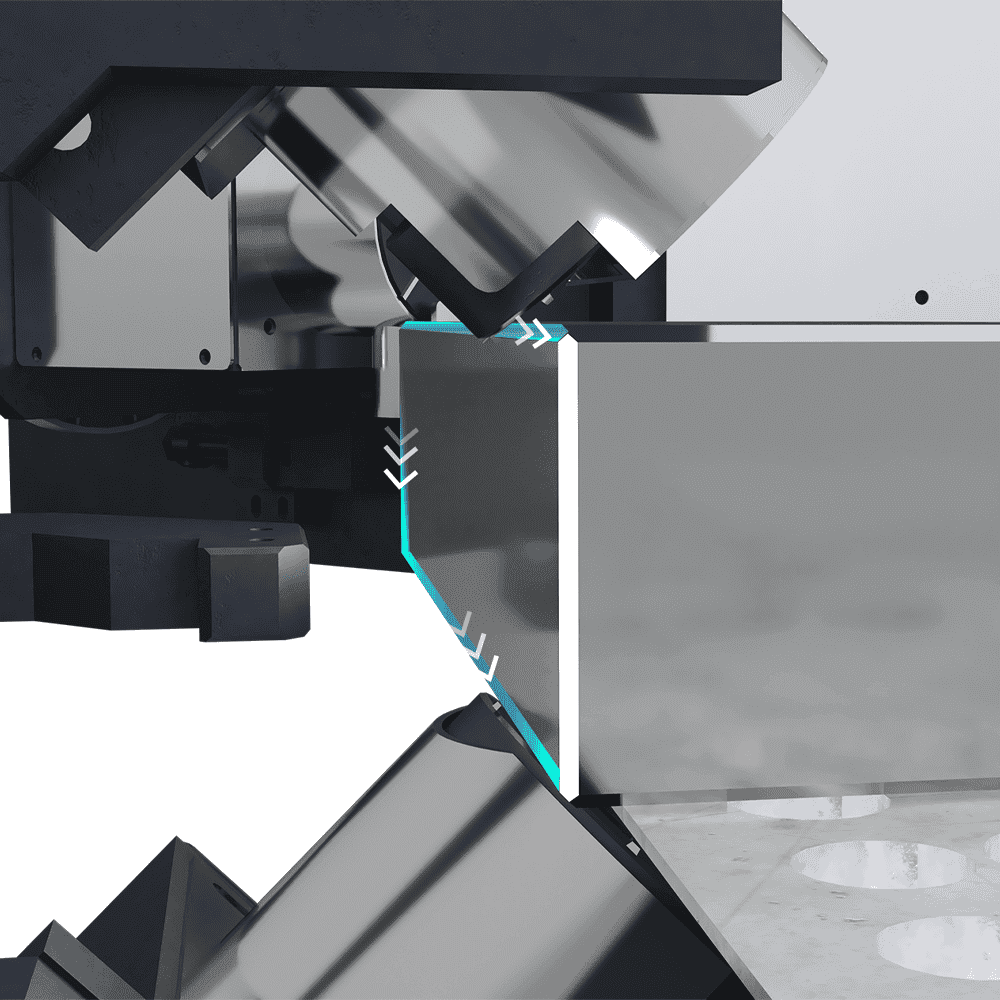

Three-head linkage chamfering

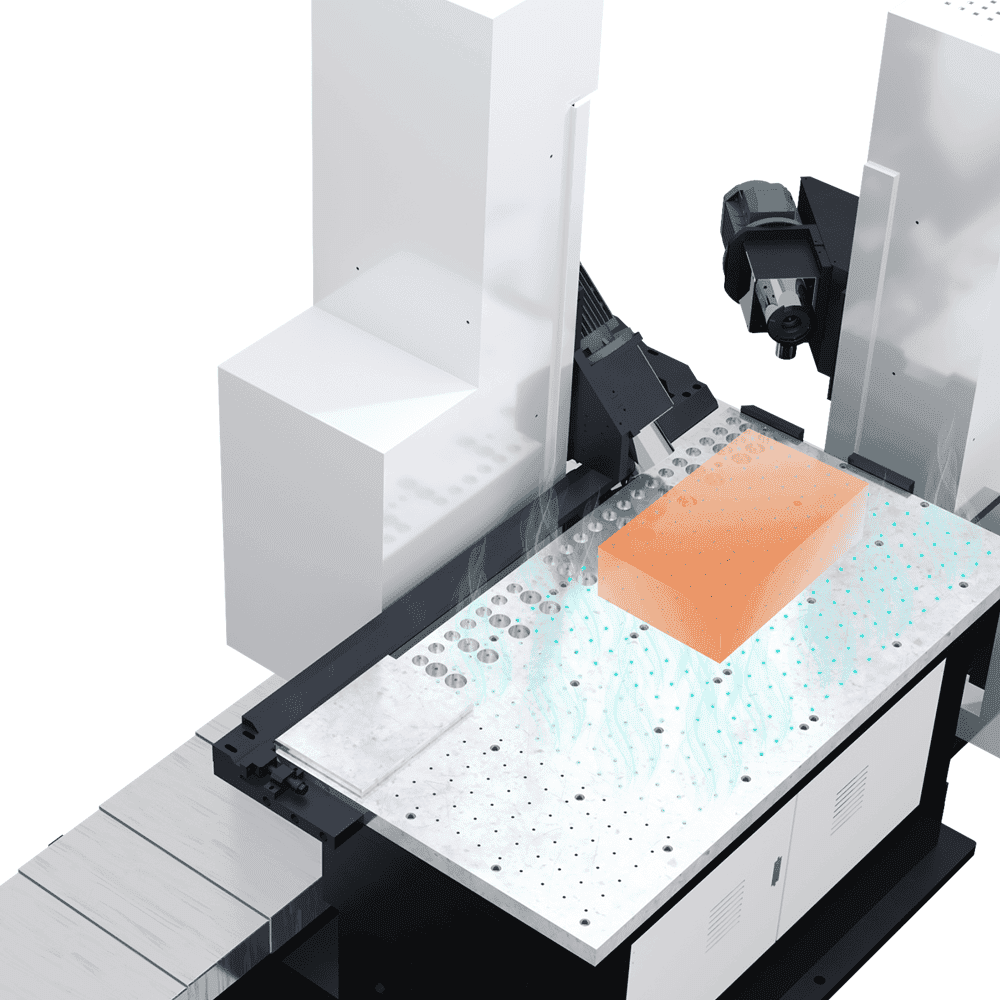

The protective cover can be optional to effectively prevent splashing of chips and cutting fluid. Enhanced Chip Handling Capability.

Air-floating powerful magnetic workbench

The castings use dovetails and multi-box type structures, allowing for minimal stress and resistance to torsional deformation, and excellent vibration absorption performance.

| Items | Value | Unit | ||||||

| Worktable | Worktable size | 800*1550 | mm | |||||

| Max. load capacity | 2000 | KG | ||||||

| Processing range | Number of control axes | 5 | / | |||||

| Maximum chamfer | c4 | / | ||||||

| Processing range | (20-300)*(150-800)*(150-1400) | mm | ||||||

| Spindle | Spindle speed | 2825 | rpm | |||||

| Spindle motor power | 0.75 | KW | ||||||

| Cutter diameter | ∮90 | mm | ||||||

| Feed speed | Servo motor | 1.0/1.0/1.0/1.0/1.5 | kw | |||||

| Maximum rapid feed rate | 10 | mm / min | ||||||

| Maximum cutting feed rate | 4 | mm / min | ||||||

| Suction cup | Specifications | 800*1400 | mm | |||||

| Tank | Capacity | 1.5 | L | |||||

| Size & weight | Machine weight | About3400 | KG | |||||

| Machine size ( L*W*H ) | 3400*1700*2060 | mm | ||||||

Contact us for more information on our Custom Made Machine Tools Solutions for complex workpieces. When you need high rigidity, efficiency and powerful machines,Asiatools Machinery gets you going!

To meet your different processing needs, we provide three widely used systems on the market for you to choose.

FANUC CONTROLLER

Fanuc oi-MF Plus 10.4'' Touch screen control panel Fanuc oi-MF Plus 10.4'' keyboard control panel. The simple and functional panel, the comfortable operational functional keyboard panel. User-friendly interface and Easy conversational operating program.

MITSUBISHI CONTROLLER

Mitsubishi-M80 series 10.4''Touch screen control panel Mitsubishi-E80 series 8.4'' keyboard control panel. The simple and functional panel, the comfortable operational functional keyboard panel. User-friendly interface and Easy conversational operating program.

CHINA CONTROLLER

JK 15'' Touch screen control panle. Easy operating program. Big and simple operating interface as smart phone touchscreen.Our relationship with clients doesn't end with the sale. We offer comprehensive after-sales support that encompasses everything from expert installation services to hands-on training sessions, ensuring your team is fully equipped to operate and maintain our machinery. Our responsive customer service and technical support are always at your disposal, providing solutions and assistance to keep your operations running smoothly