Steel for Mold Industry with Comprehensive Machining Solutions

Trusted by mold makers woldwide for over 12 years.

Trusted by mold makers woldwide for over 12 years.

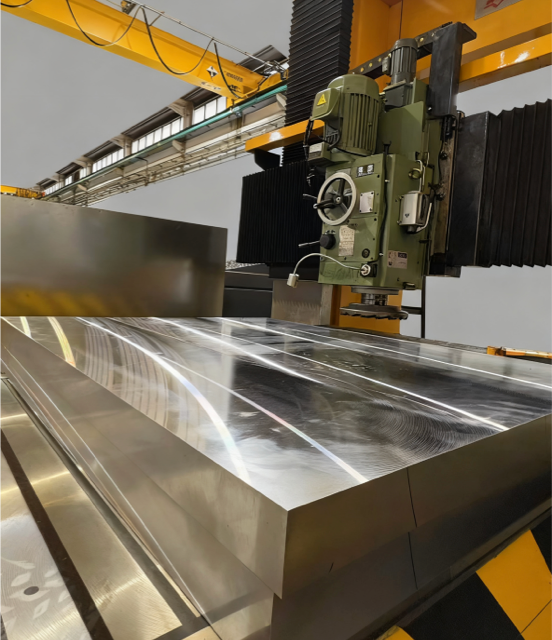

At ASIATOOLS, we are equipped with electric arc furnace and induction furnace designed to handle demanding industrial applications. Our large-capacity Furnaces enable us to process wide range of high-performance steel materials.

Max Ingot Diameter:

Ø800mm (31.5 inches)

Max Length:

6000mm (236 inches)

Max Weight:

Up to 15 tons

Applicable Materials:

Carbon steel ,Mold steel, Tool steel, Alloy steel,Stainless steelsteel

Lower Unit Cost for Large Orders

Shorter Lead Times for Large Components

Custom Production Flexibility

We offer various types of C45, 1.2311, 1.2312, 1.2738, 1.2343, 1.2344, 1.2083, 1.2085, 1.2714, and 1.2379—they are widely used in plastic mold manufacturing. Each material offers unique properties to meet various mold requirements. See the comparison below for key performance differences:

Category

Carbon structure steel

Delivery condition

Hot rolled & Hot forged

Supply form

Round bar, Flat bar, Square bar, Plate, Block, Tube

1045 steel is a medium-carbon steel under the AISI designation system. The “10” denotes plain carbon steel, and “45” indicates ~0.45% carbon content. It typically contains 0.60–0.90% Mn to enhance strength and toughness, 0.15–0.35% Si for deoxidation, and minimal P and S, which can cause cold or hot brittleness. Equivalent grades include EN/DIN C45E (1.1191), JIS S45C, and GB 45.

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| #45 | 1045 | S45C | 1.1730 | HB≤229 | 0.42-0.48 | 0.15-0.35 | 0.60-0.90 | ≤0.03 | ≤0.035 | 0.4 | ≤0.2 | ≤0.2 | - |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| #45 | 1045 | S45C | 1.1730 | HB≤229 |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.42-0.48 | 0.15-0.35 | 0.60-0.90 | ≤0.03 | ≤0.035 | 0.4 | ≤0.2 | ≤0.2 | - |

Category

Plastic mold steel

Delivery condition

Hot rolled & forged

Supply form

Flat bar,Square bar,Plate/Block,Round bar

1.2311 is a pre-hardened plastic mold steel. It offers a well-balanced combination of toughness, strength, and machinability, making it one of the most widely used steels in the mold industry. With good polishability and uniform hardness across sections, it is suitable for general-purpose plastic molds and tooling.

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 3Cr2Mo | P20 | HPM2 | 1.2311 | HRC:28-36 | 0.3-0.5 | 0.2-0.4 | 1.3-1.6 | ≤0.03 | ≤0.03 | 1.8-2.1 | - | 0.1-0.3 | - |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| 3Cr2Mo | P20 | HPM2 | 1.2311 | HRC:28-36 |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.3-0.5 | 0.2-0.4 | 1.3-1.6 | ≤0.03 | ≤0.03 | 1.8-2.1 | - | 0.1-0.3 | - |

Category

Plastic mold steel

Delivery condition

Hot rolled & forged

Supply form

Flat bar, Square bar, Plate/Block, Round bar

1.2312 is a sulfur-alloyed modification of 1.2311, designed for enhanced machinability. The addition of sulfur improves cutting performance, making it ideal for machining large or complex molds with reduced tool wear and production time.

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 3Cr2Mo+S | P20+S | - | 1.2312 | HRC:28-36 | 0.35-0.45 | 0.3-0.5 | 1.4-1.6 | ≤0.03 | ≤0.1 | 1.8-2.1 | - | 0.15-0.25 | - |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| 3Cr2Mo+S | P20+S | - | 1.2312 | HRC:28-36 |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.35-0.45 | 0.3-0.5 | 1.4-1.6 | ≤0.03 | ≤0.1 | 1.8-2.1 | - | 0.15-0.25 | - |

Category

Plastic mold steel

Delivery condition

Hot rolled & forged

Supply form

Flat bar, Square bar, Plate/Block, Round bar

1.2738 is a nickel-alloyed variant of 1.2311, engineered to provide improved toughness, hardness uniformity, and excellent polishability across large cross-sections. Supplied pre-hardened in the range of 33–38 HRC, it maintains consistent mechanical properties even in thick sections. Its high surface finish capability makes it especially suitable for molds used in transparent or high-gloss plastic products.

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 3Cr2MnNIMo | P20+NI | HPM7/PX5 | 1.2738 | HRC:33-38 | 0.35-0.45 | 0.2-0.5 | 1.2-1.6 | - | - | 1.8-2.1 | - | 0.15-0.25 | - |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| 3Cr2MnNIMo | P20+NI | HPM7/PX5 | 1.2738 | HRC:33-38 |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.35-0.45 | 0.2-0.5 | 1.2-1.6 | - | - | 1.8-2.1 | - | 0.15-0.25 | - |

Category

Hot Work Tool Steel

Delivery condition

Hot rolled & Hot forged, Soft annealed to max. 220HB

Supply form

Round bar, Flat bar, Square bar, Plate

Chromium hot-work tool steels are classified as group H (H1–H19) by AISI. H13 is the most widely used grade for hot and cold work tooling, valued for its toughness and fatigue resistance.

Equivalent grades include EN/DIN 1.2344 (X40CrMoV5-1), JIS SKD61, GB 4Cr5MoSiV1, and GOST 4Х5МФ1С.

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 4Cr5MoSIV1 | H11 | SKDG | 1.2343 | HR≤230 | 0.36-0.38 | 1 | 0.4-0.55 | - | - | 5.0-5.15 | - | 1.2-1.3 | 0.35-0.4 |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| 4Cr5MoSIV1 | H11 | SKDG | 1.2343 | HR≤230 |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.36-0.38 | 1 | 0.4-0.55 | - | - | 5.0-5.15 | - | 1.2-1.3 | 0.35-0.4 |

Category

Hot Work Tool Steel

Delivery condition

Hot rolled & Hot forged, Soft annealed to max. 229HB

Supply form

Round bar, Flat bar

Chromium hot-work tool steels are classified as group H steels by the AISI classification system. This series of steels start from H1 to H19.

H11 tool steel equivalent material includes European EN, ISO, German DIN 1.2343/X37CrMoV5-1, Japanese JIS standard SKD 6, Chinese GB 4Cr5MoSiV, Rusia GOST 4Х5МФС, etc

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 4Cr5MoSIV1 | H13 | SKD61/DHA1 | 1.2344 | HR≤230 | 0.32-0.45 | 0.8-1.2 | 0.2-0.4 | - | ≤0.03 | 4.7-5.5 | - | 1.1-1.5 | 0.8-1.2 |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| 4Cr5MoSIV1 | H13 | SKD61/DHA1 | 1.2344 | HR≤230 |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.32-0.45 | 0.8-1.2 | 0.2-0.4 | - | ≤0.03 | 4.7-5.5 | - | 1.1-1.5 | 0.8-1.2 |

Category

Stainless steel

Delivery condition

Hot rolled & forged

Supply form

Flat bar, Square bar, Plate/Block, Round bar

1.2083 is a martensitic stainless tool steel with high chromium content (~13%), giving it excellent corrosion resistance, high wear resistance, and good polishability. It is typically supplied in the quenched and tempered condition with hardness ranging from 48–52 HRC. Its ability to maintain a high surface finish and resist attack from chemically aggressive plastics makes it a premium choice for demanding mold applications.

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 4Cr13ESR | 420ESR | S-STAR-A | 1.2083ESR | HB≤240 | 0.36-0.45 | ≤0.8 | ≤0.8 | ≤0.03 | ≤0.003 | 12-14 | - | ≤0.3 | ≤0.3 |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| 4Cr13ESR | 420ESR | S-STAR-A | 1.2083ESR | HB≤240 |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.36-0.45 | ≤0.8 | ≤0.8 | ≤0.03 | ≤0.003 | 12-14 | - | ≤0.3 | ≤0.3 |

Category

Stainless steel

Delivery condition

Hot rolled & forged

Supply form

Flat bar, Square bar, Plate/Block, Round bar

1.2085 is a stainless mold steel similar to 1.2083 but with sulfur added (~0.05–0.10%), which significantly improves machinability. It maintains good corrosion resistance and reasonable hardness (typically 30–36 HRC in pre-hardened condition). While it does not reach the same polishability level as 1.2083 due to sulfur inclusions, it is a cost-effective solution for medium-grade stainless mold applications where machining speed and corrosion resistance are both required.

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 3Cr16NIMoVS | 420+S | ROYALLOY | 1.2085 | HRC:30-36 | 0.38 | 0.3 | 0.8 | - | - | 15 | - | - | - |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| 3Cr16NIMoVS | 420+S | ROYALLOY | 1.2085 | HRC:30-36 |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.38 | 0.3 | 0.8 | - | - | 15 | - | - | - |

Category

Hot Work Tool Steel

Delivery condition

Hot rolled & Hot forged, Soft annealed to max. 220HB

Supply form

Round bar, Flat bar, Square bar, Plate

L6 steel is widely used in fields such as tool manufacturing. Its main alloying elements include chromium (Cr), nickel (Ni), molybdenum (Mo), etc., and the addition of these alloying elements endows L6 steel with unique properties.

L6 tool steel equivalent material includes European EN, ISO, German DIN 1.2714/55NiCrMoV7, Japanese JIS standard SKT4, Chinese GB 5CrNiMo, Rusia GOST 5ХНМ, etc

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 5CrNiMO | L6 | SKTT4 | 1.2714 | - | 0.5-0.6 | 0.1-0.4 | 0.6-0.9 | <=0.03 | <=0.03 | 0.8-1.2 | 0.8-1.2 | 0.35-0.55 | 0.05-0.15 |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| 5CrNiMO | L6 | SKTT4 | 1.2714 | - |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.5-0.6 | 0.1-0.4 | 0.6-0.9 | <=0.03 | <=0.03 | 0.8-1.2 | 0.8-1.2 | 0.35-0.55 | 0.05-0.15 |

Category

Category Cold work tool steel

Delivery condition

Delivery condition Hot rolled&Hot forged,annealed to max.255HB

Supply form

Supply form Round bar,Flat bar,Sheet

AISI D2 steel is a high-carbon, high-chromium, tungsten-containing cold work tool steel. Its main alloying elements include carbon, silicon, manganese, chromium, and tungsten, while the phosphorus and sulfur contents are each limited to a maximum of 0.03%.

Equivalent grades of D2 cold work tool steel include:

● European/ISO: 1.2601 (X165CrMoV12), 1.2379 (X153CrMoV12)

● Japanese JIS: SKD11

● Chinese GB: Cr12MoV / Cr12Mo1V1

| Corresponding international common brands | Hardness | Chemical Composition(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| Cr12Mov | D2 | SKD11 | 1.2379 | - | 1.4-1.6 | 0.1-0.6 | 0.1-0.6 | <=0.03 | <=0.03 | 11.0-13.0 | - | 0.7-1.2 | 0.5-1.1 |

| Corresponding international common brands | Hardness | |||

|---|---|---|---|---|

| CHINA | US | JAPAN | GERMNAY | |

| Cr12Mov | D2 | SKD11 | 1.2379 | - |

| Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 1.4-1.6 | 0.1-0.6 | 0.1-0.6 | <=0.03 | <=0.03 | 11.0-13.0 | - | 0.7-1.2 | 0.5-1.1 |

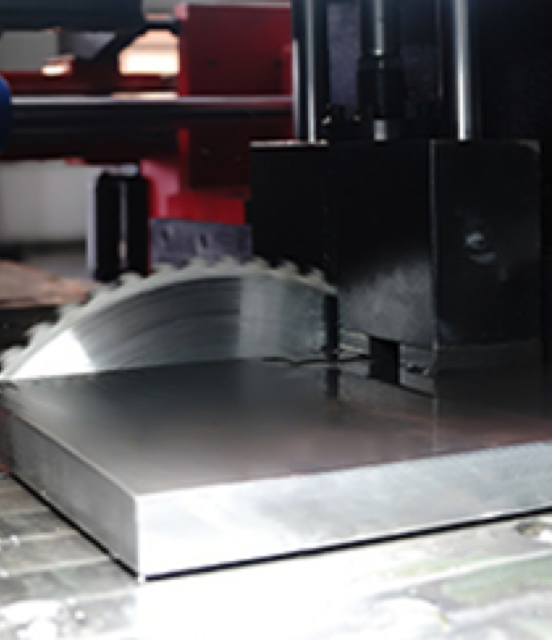

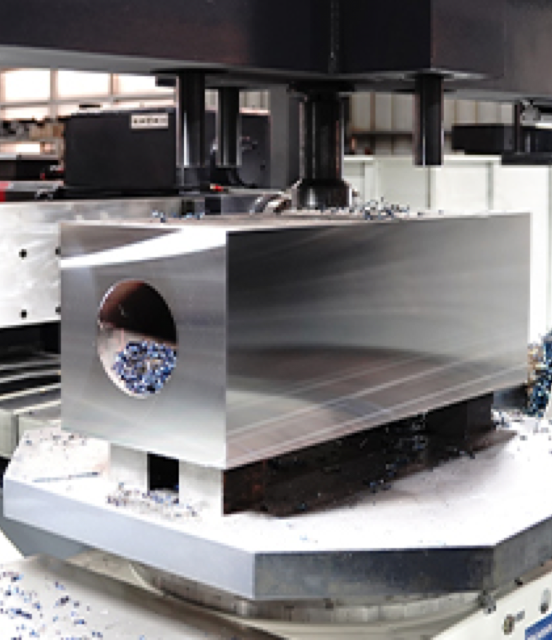

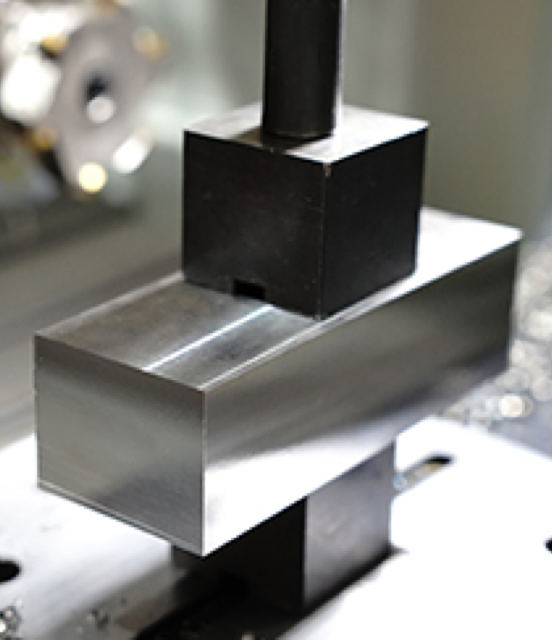

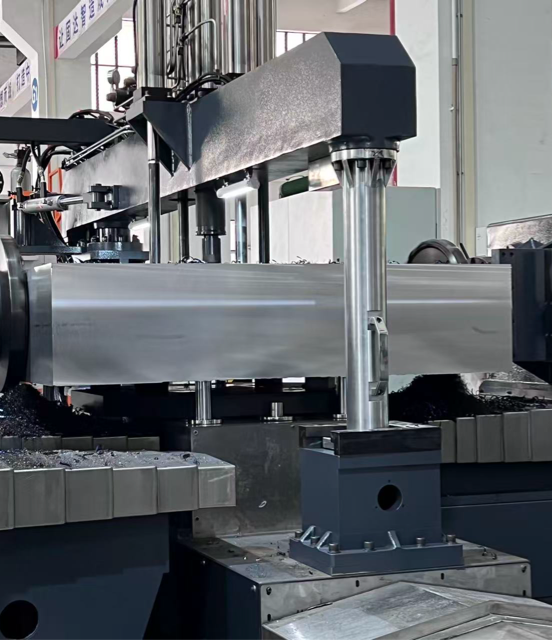

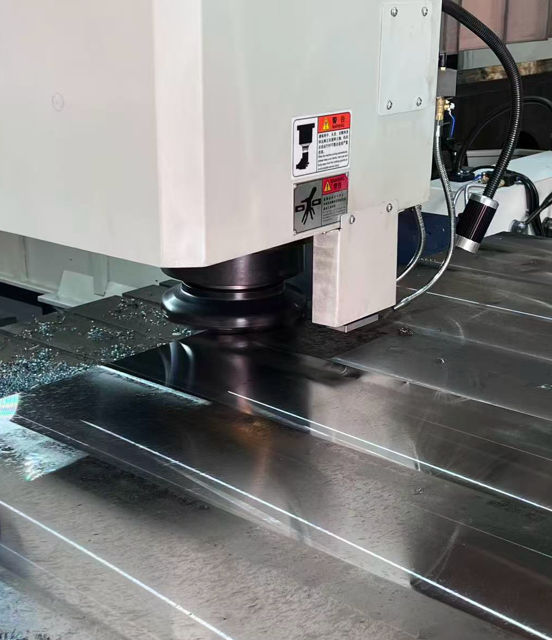

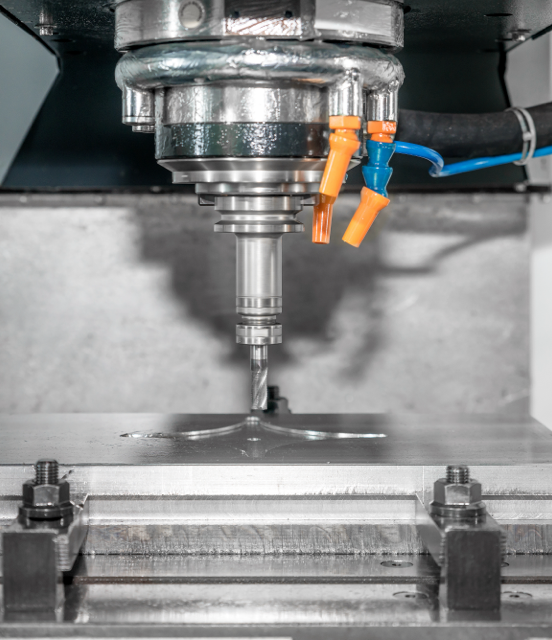

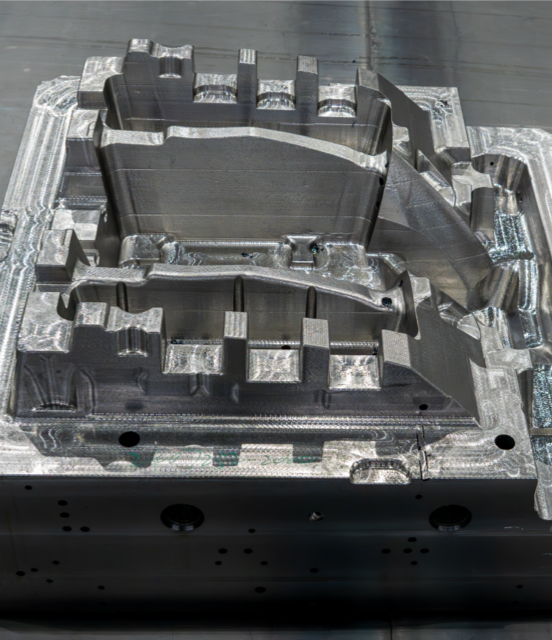

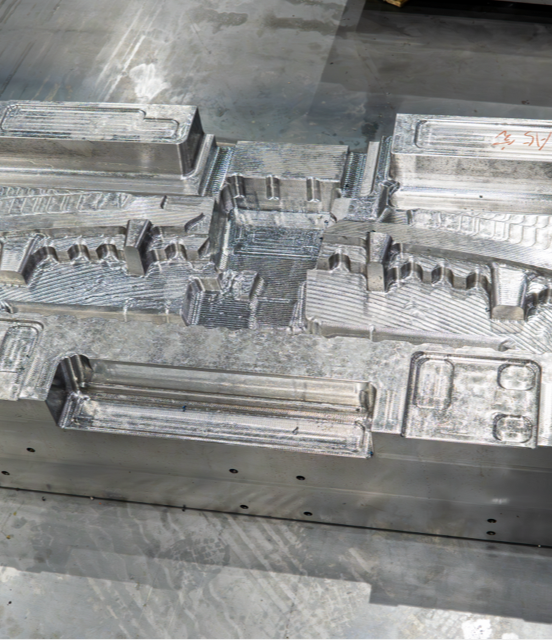

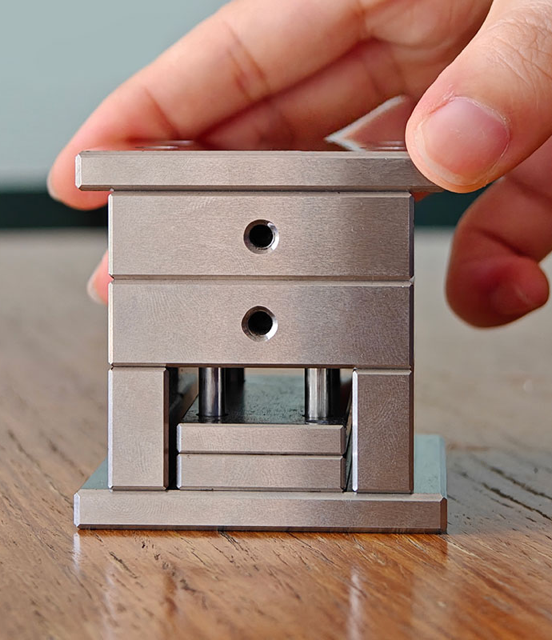

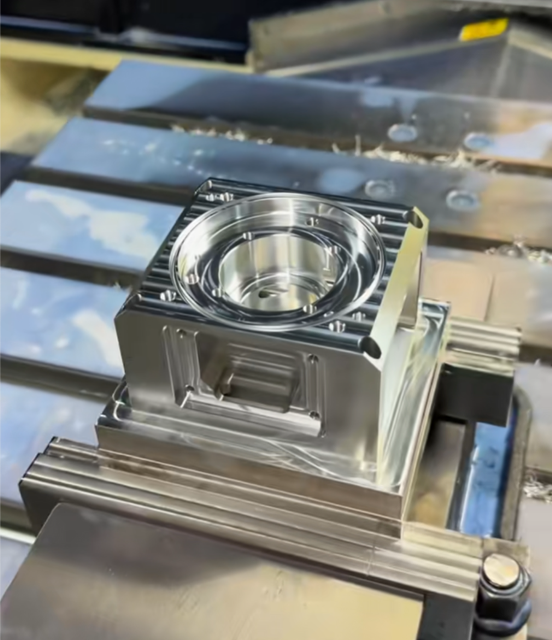

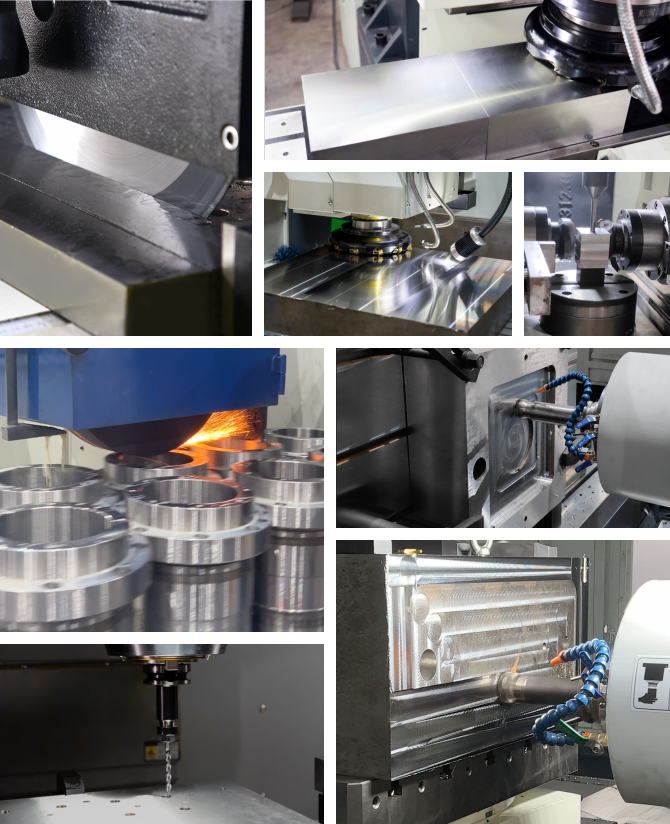

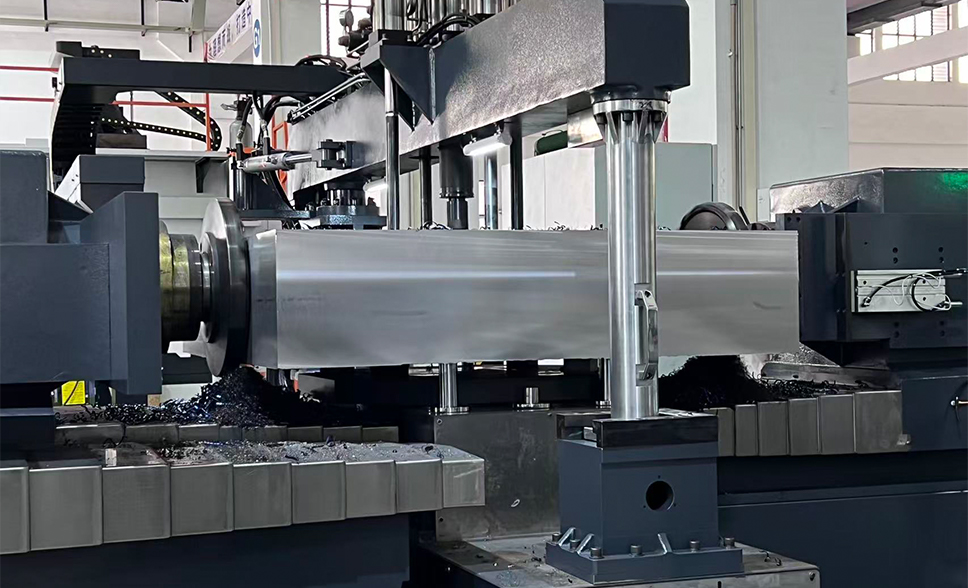

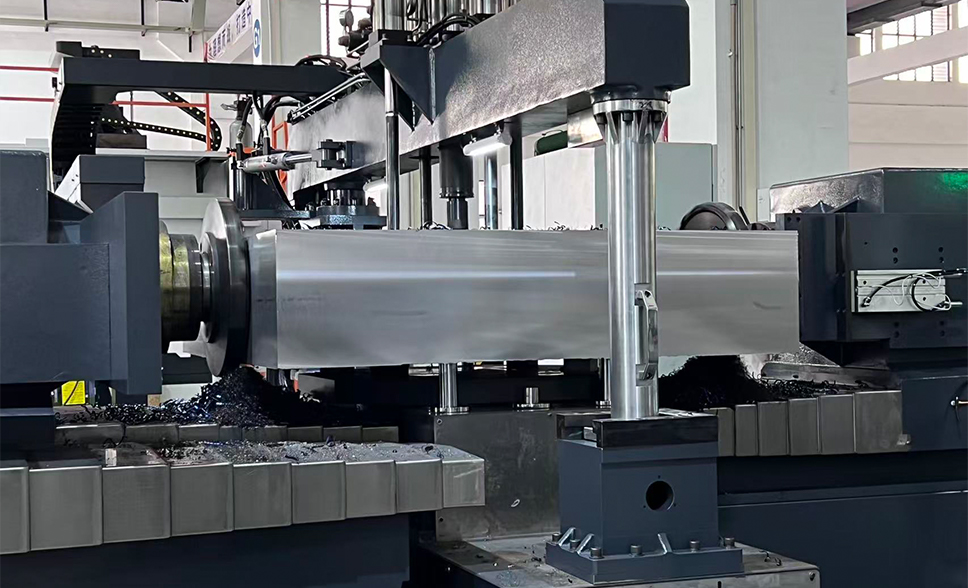

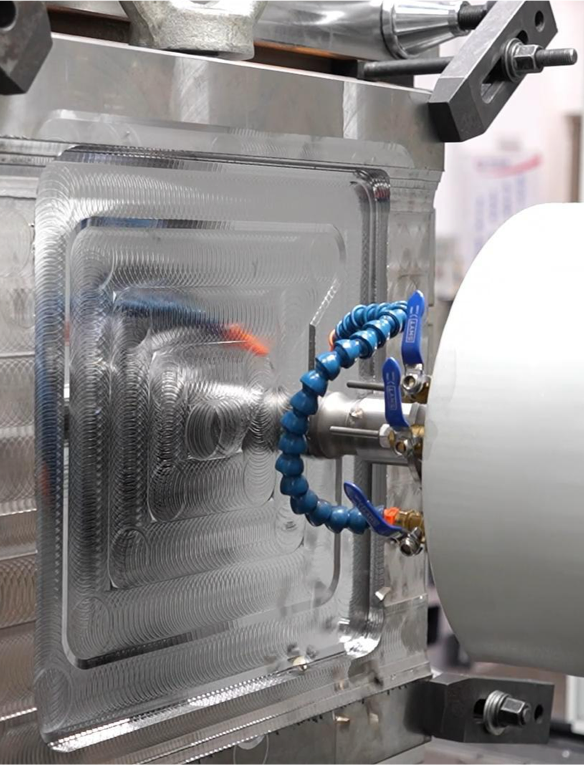

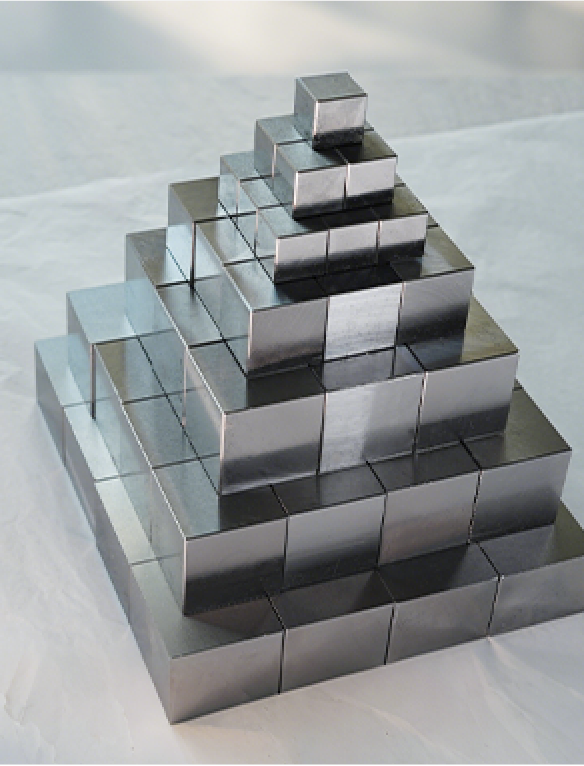

When you order our mold steel, machining is included free of charge. Backed by our self-manufactured CNC machines, we offer reliable and cost-effective processing for every steel block we deliver.

To explore more, visit our MOLD AND DIE Service Page or Contact Us for personalized consultation and processing solutions.

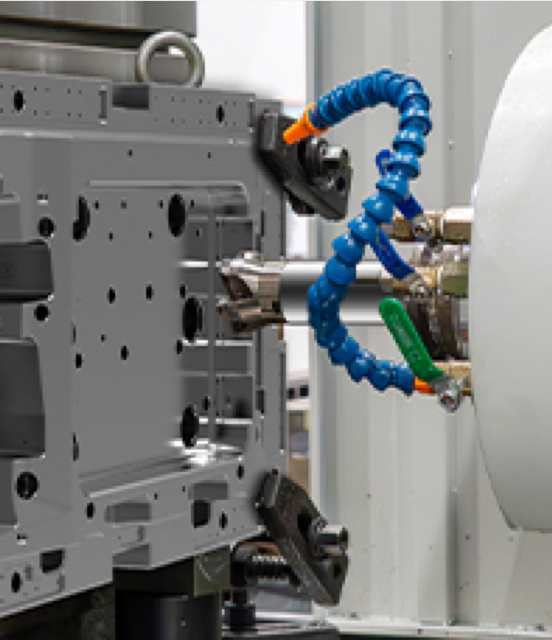

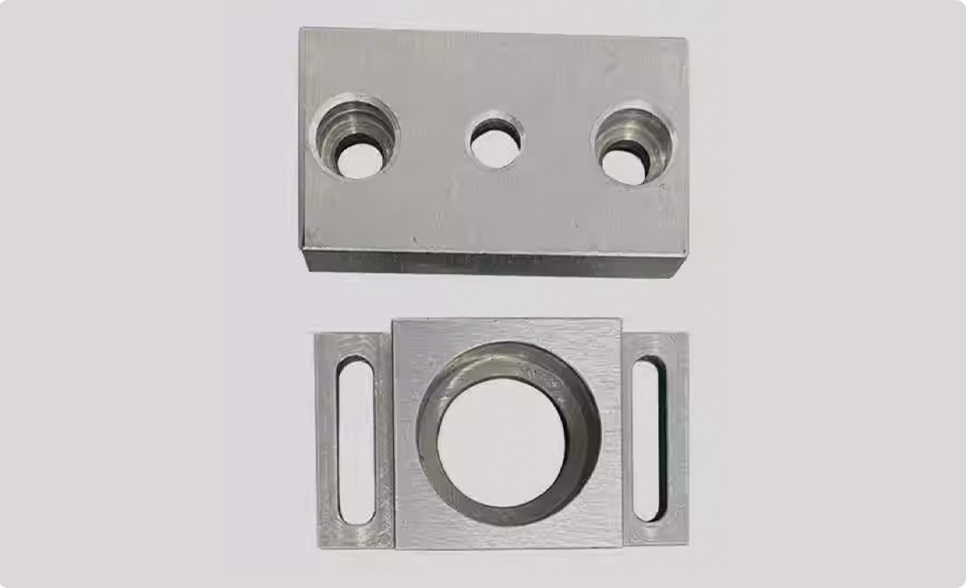

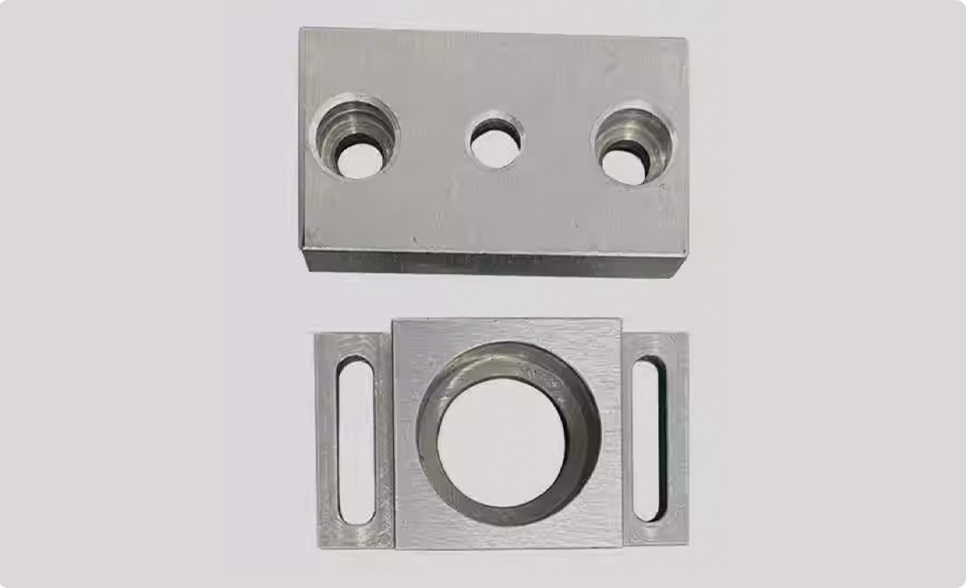

We understand that mold construction is complex and involves more than just the processing of large modules, mold frames, and bases. It also requires precision parts such as mold inserts, ejection pins, locating rings, slides, and more. To meet these needs, we offer small precision machining services as well as custom component machining for the mold industry. For more details, visit our Precision Machining Service page to upload your part files, or contact us directly for personalized, one-on-one support.

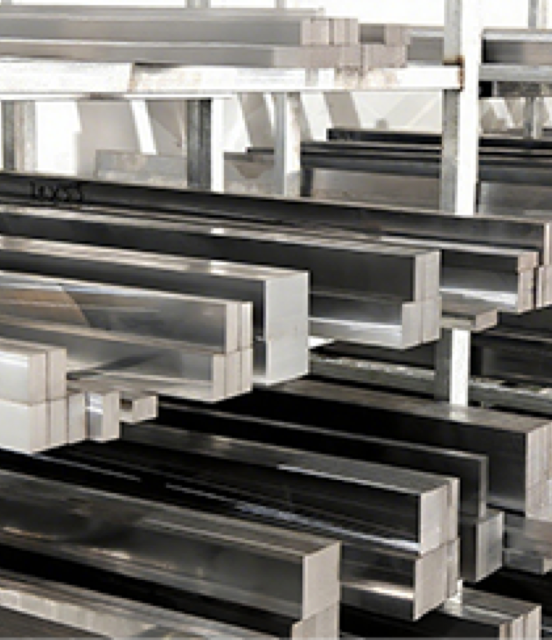

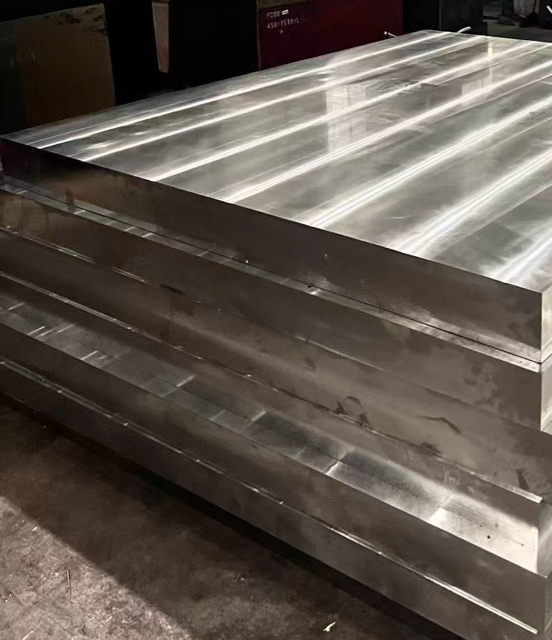

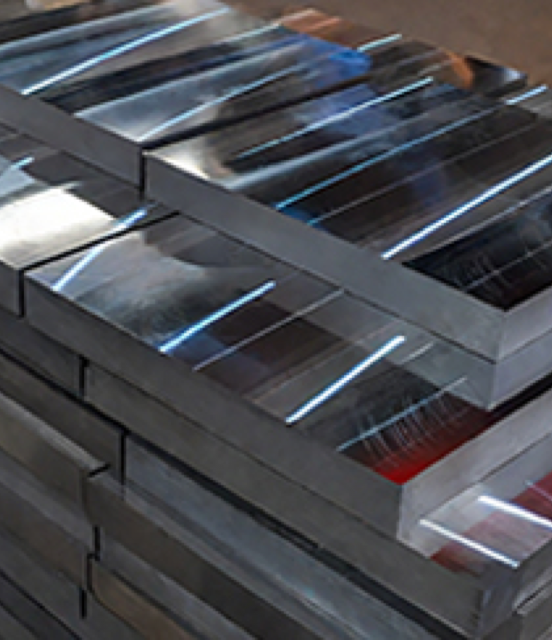

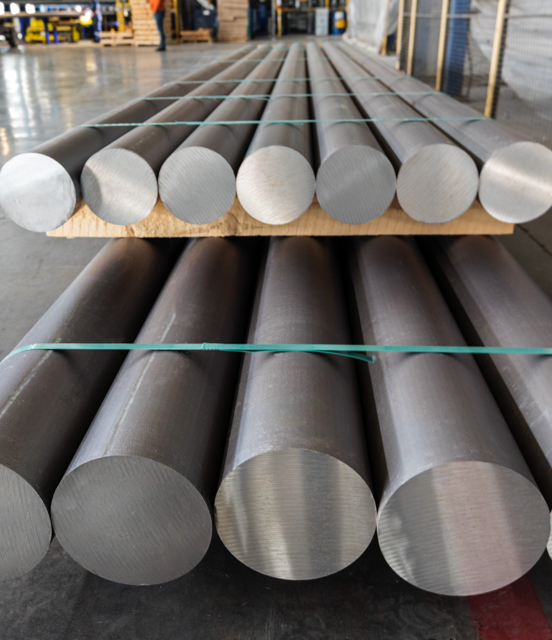

Large Inventory Ready

Large Inventory Ready

Comprehensive Machining Solutions

Comprehensive Machining Solutions

Full Dimensional Range

Full Dimensional Range

Fast Delivery Time

Fast Delivery Time

Finished Product Inspection

Finished Product Inspection

12+ Years of Experience

12+ Years of Experience