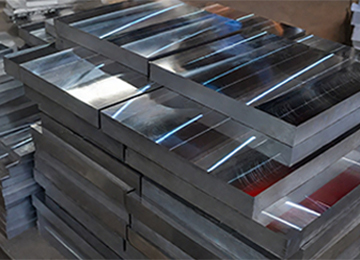

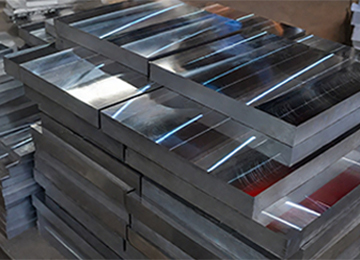

Large Inventory of Mold Steels • Full Machining Services • Fast Delivery

Steel Type: 1045 / 1.2311 / 1.2343 / 1.2344 / 1.2312 / 1.2738 / 1.2083 / 1.2085 / 12CrMo & more

ASIATOOLS is a trusted supply chain partner for the mold & die industry—from raw materials like mold steel to finished parts, CNC machines and accessories. Every supplier and product is carefully vetted, industry-approved, and quality-guaranteed, saving you valuable time and effort.

Years Experience

Employees

Patented Technologies

Ft2 factory Size

Years Experience

Employees

Patented Technologies

Ft2 factory Size

Steel for Mold Industry with Full Machining Service

If you are looking for affordable mold steel that comes with reliable machining services, we are your best choice. With our own in-house machines, we provide a full range of processing solutions—including surface milling, frame cutting, rough machining, CNC part machining, and shaft machining, etc.

Learn More

Complete Production Line for Cubic Workpiece Machining

Our machine lineup covers the entire process—from sawing, six-sided milling & grinding, to machining centers for drilling and advanced operations. Each stage is supported by specialized equipment, designed for heavy cutting, fast surface milling, and maximum efficiency. With this integrated solution, you can achieve precise machining, reduced setup time, and significantly improved productivity.

Learn More

Extensive CNC Accessory Resources at Your Service

We provide a wide selection of CNC machine accessories, ranging from tool carts, fixtures, and measuring instruments to air guns and more. Every accessory is carefully sourced and strictly tested to ensure consistent quality and reliability. With our comprehensive accessory solutions, you gain the resources needed to enhance productivity and streamline your machining operations.

Learn More

Steel for Mold Industry with Full Machining Service

If you are looking for affordable mold steel that comes with reliable machining services, we are your best choice. With our own in-house machines, we provide a full range of processing solutions—including surface milling, frame cutting, rough machining, CNC part machining, and shaft machining, etc.

Complete Production Line for Cubic Workpiece Machining

Our machine lineup covers the entire process—from sawing, six-sided milling & grinding, to machining centers for drilling and advanced operations. Each stage is supported by specialized equipment, designed for heavy cutting, fast surface milling, and maximum efficiency. With this integrated solution, you can achieve precise machining, reduced setup time, and significantly improved productivity.

Extensive CNC Accessory Resources at Your Service

We provide a wide selection of CNC machine accessories, ranging from tool carts, fixtures, and measuring instruments to air guns and more. Every accessory is carefully sourced and strictly tested to ensure consistent quality and reliability. With our comprehensive accessory solutions, you gain the resources needed to enhance productivity and streamline your machining operations.

Our process goes beyond mere transactions; it's about establishing a lasting relationship founded on trust and understanding. We are dedicated to understanding our users' needs and offering comprehensive CNC solutions that match those requirements,ensuring both satisfaction and long-term success.

Needs Analysis & Market Reserch

Needs Analysis & Market Reserch

Function & Performance Evaluation

Function & Performance Evaluation

Supplier Evaluation

Supplier Evaluation

Testing and Verification

Testing and Verification

Continuous Evaluation & Feedback

Continuous Evaluation & Feedback

ASIATOOLS is backed by GOODA MACHINERY, a formidable influencer in the CNC industry. This strategic partnership provides us with robust financial support and abundant resources, enabling us to maintain our leading position in the market. With GOODA MACHINERY's backing, we have access to cutting-edge technology, advanced manufacturing facilities, and a wealth of industry expertise. This ensures that we can consistently innovate and deliver high-quality CNC machines and accessories that meet the evolving needs of our customers.

Our extensive global resource network guarantees that our customers have access to a wide variety of high-quality CNC machines and accessories. This robust supply chain allows us to meet the dynamic needs of the market, ensuring that you always have the right products at the right time, enhancing both efficiency and reliability in your operations. With ASIATOOLS, you benefit from unparalleled product diversity and supply stability, making us your ultimate partner in the CNC industry.

Our expert evaluation team, comprising over 100 industry specialists, strictly tests each product to ensure the highest quality. These professionals bring a wealth of experience and technical expertise, enabling them to understand the critical factors in the CNC industry, from CNC machines to CNC accessories.

At ASIATOOLS, we understand that exceptional service doesn't end at the point of sale. Our comprehensive after-sales support system is designed to ensure your continued satisfaction and operational success. From installation and training to maintenance and troubleshooting, our dedicated team is always ready to assist. We offer worldwide service support, providing timely and efficient solutions to any issues you may encounter, making your purchasing experience truly worry-free.

At ASIATOOLS, we believe in building strong, mutually beneficial partnerships.

We are happy to keep you informed with the latest company updates and industry news. Our news section will be regularly updated with important announcements, product launches, technological advancements, and insights into market trends. Stay tuned to remain at the forefront of the CNC machines and tool accessories industry with ASIATOOLS.

CNC Grinding Machine: Troubleshooting & Tips for Hard Material Grinding

Master CNC grinding machine tips for hard materials, solve common issues like surface burns, and boost precision in mold & mechanical part finishing.

CNC Duplex Milling Machine: Precision Machining of Four Side Faces

CNC duplex milling machines deliver fast, accurate four-side machining, boosting parallelism, perpendicularity, and efficiency for mold and steel blocks.

Horizontal Milling Machine Guide: Boosting Production Efficiency

Learn why horizontal milling machines offer superior rigidity, chip control, and multi-face machining for mass production.

Three plate mold structure and working process guide

A quick guide to three-plate mold structure, opening sequence, advantages, and common applications in injection molding.