Mold Semi-finished Product

Processing Solution

For clients with low daily production volumes, the cost of purchasing CNC machine tools for mold processing is often high. This not only involves the cost of purchasing the equipment but also includes expenses for installation, commissioning, daily maintenance, and training of operators. For such clients, the investment return period for mold processing is relatively long, and the usage frequency of the equipment may not be sufficient to cover its high costs.

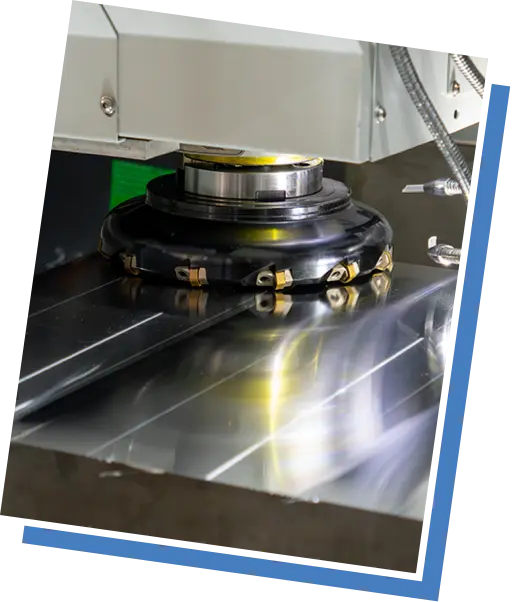

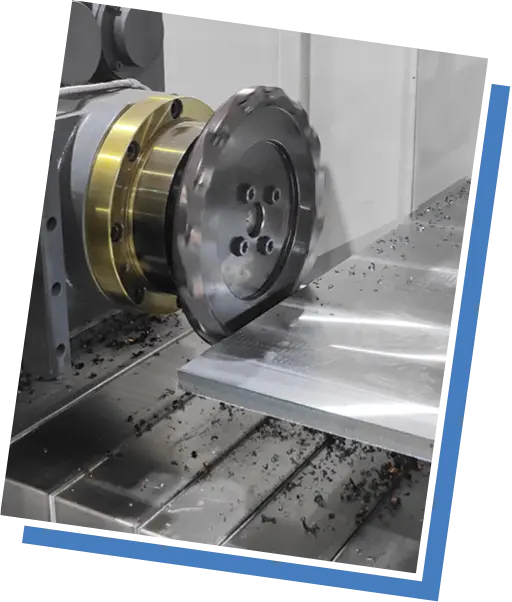

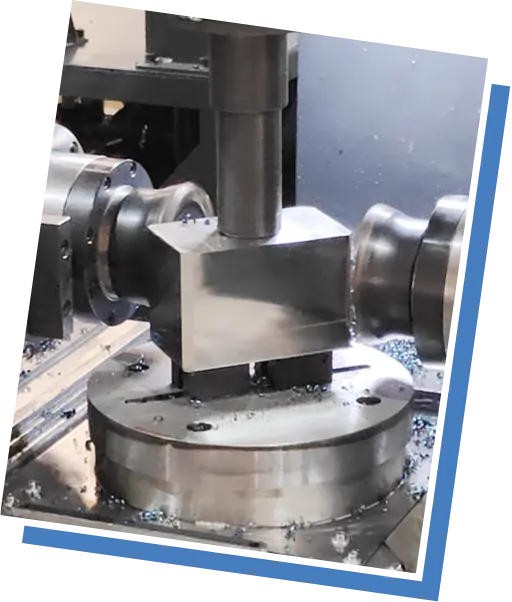

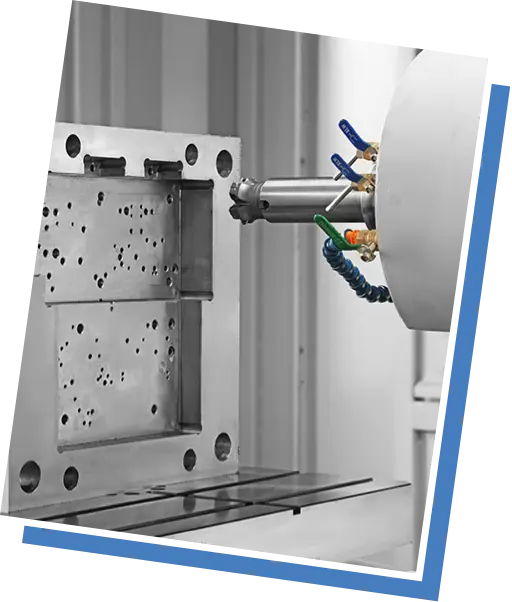

As a result, many clients prefer to purchase pre-processed mold semi-finished products directly to reduce investment and risk. ASIATOOLS can provide this solution. We offer high-quality mold semi-finished processing services, including rough machining, precision machining, and lifting hole machining of mold templates. This way, clients can obtain high-quality mold semi-finished products without investing in expensive equipment and technical personnel, thus reducing costs, shortening production cycles, and improving production efficiency.

Free Consultation

Demonstration of the Mold

Processing Procedure

Comprehensive Mold

Template Processing Service

By the end of this workflow, you’ll receive a ready-for-finishing mold module—laying a solid foundation for your production success.

Selection of Metal Materials

Various metal materials are commonly used for mold templates,

typically chosen based on the mold's purpose, processing requirements,

and desired durability. The following are some common materials.

Carbon Steel

Alloy Steel

Stainless Steel

Tool Steel

Aluminum

Brass and Bronze

Why ASIATOOLS

Choosing ASIATOOLS means unlocking greater opportunities for cost reduction and efficiency improvement.

We provide comprehensive mold process services, from rough processing to fine finishing,

ensuring that all your requirements are met with precision and quality. Our pre-sales and after-sales support teams are always ready to assist you,

offering expert guidance before your purchase and seamless service afterward.

Get in touch with our specialists today and experience high-quality solutions tailored to your needs!

Why ASIATOOLS

Choosing ASIATOOLS means unlocking greater opportunities for cost reduction and efficiency improvement.

We provide comprehensive mold process services, from rough processing to fine finishing,

ensuring that all your requirements are met with precision and quality. Our pre-sales and after-sales support teams are always ready to assist you,

offering expert guidance before your purchase and seamless service afterward.

Get in touch with our specialists today and experience high-quality solutions tailored to your needs!