VM-2340

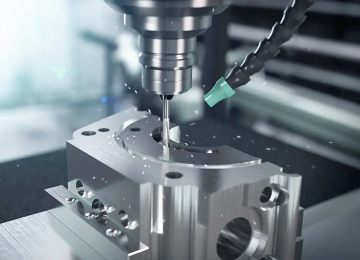

CNC Gantry Milling Machine

Process capacity:1800*4000mm. Gear box type spindles with high torque spindle motors.

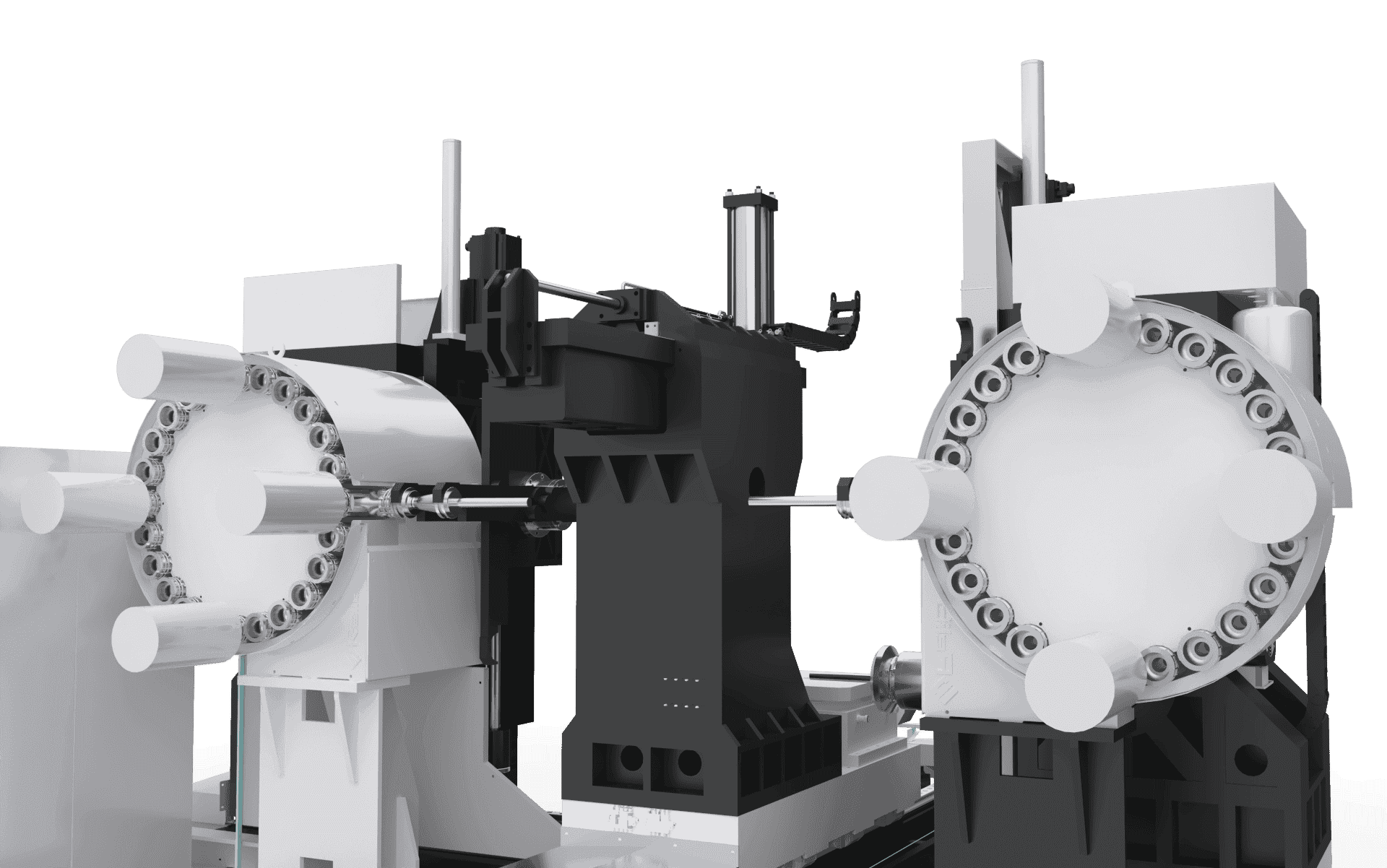

The moving column double-head horizontal milling and drilling machine series is mainly used for efficient milling, drilling, and tapping of workpieces with a thickness within the effective range such as large flat plates, wind power flanges, discs, rings, etc. It can drill through holes and blind holes in single-material parts and composite materials. The machine tool processing process is digitally controlled and the operation is very convenient.

Guide

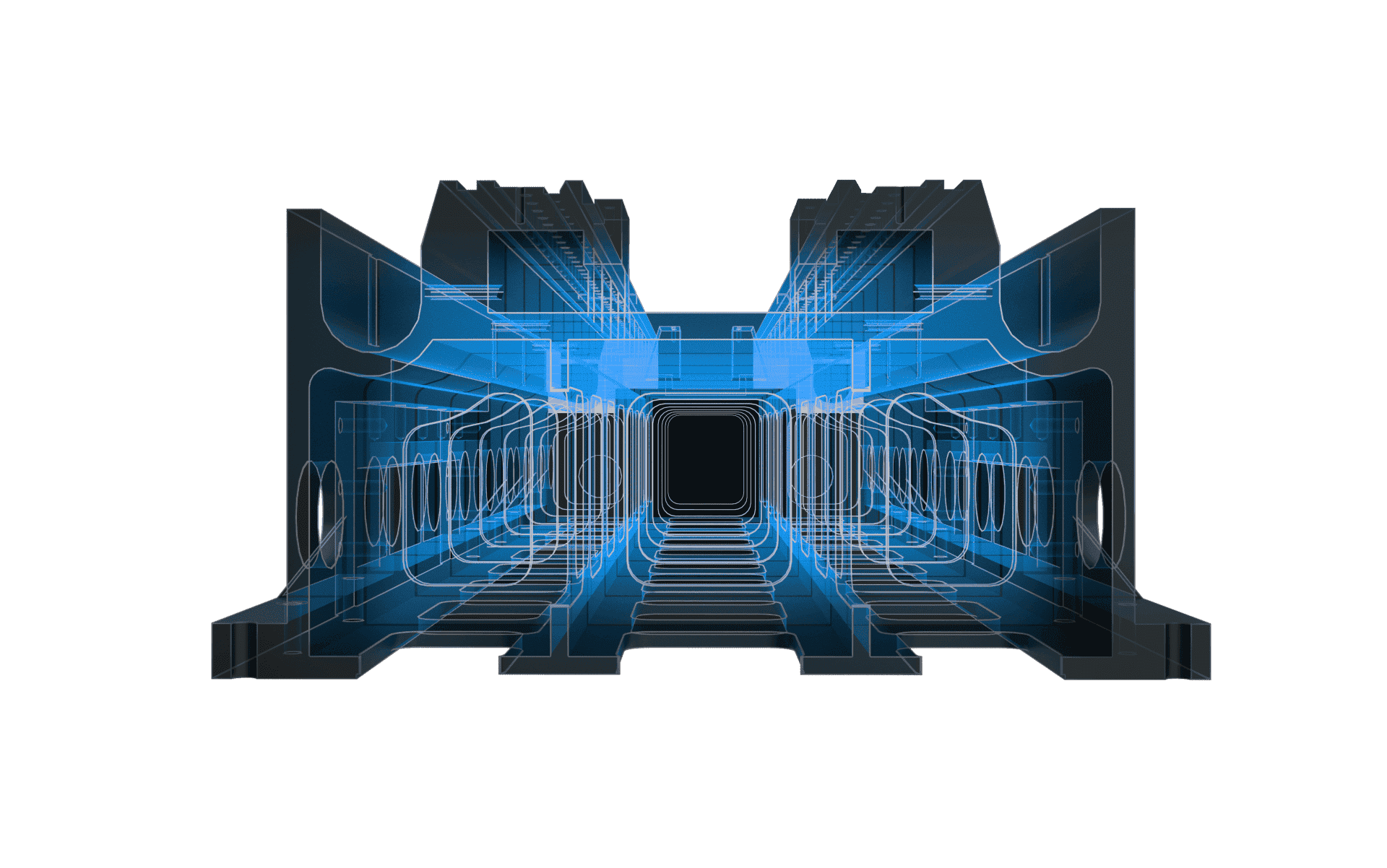

Two lines and one hard structure, the Z-axis uses high-rigidity hard rails, and the X and Y-axis use high-speed Mobile linear roller guides, suitable for heavy-duty cutting, high-rigidity-product processing, and engineering.

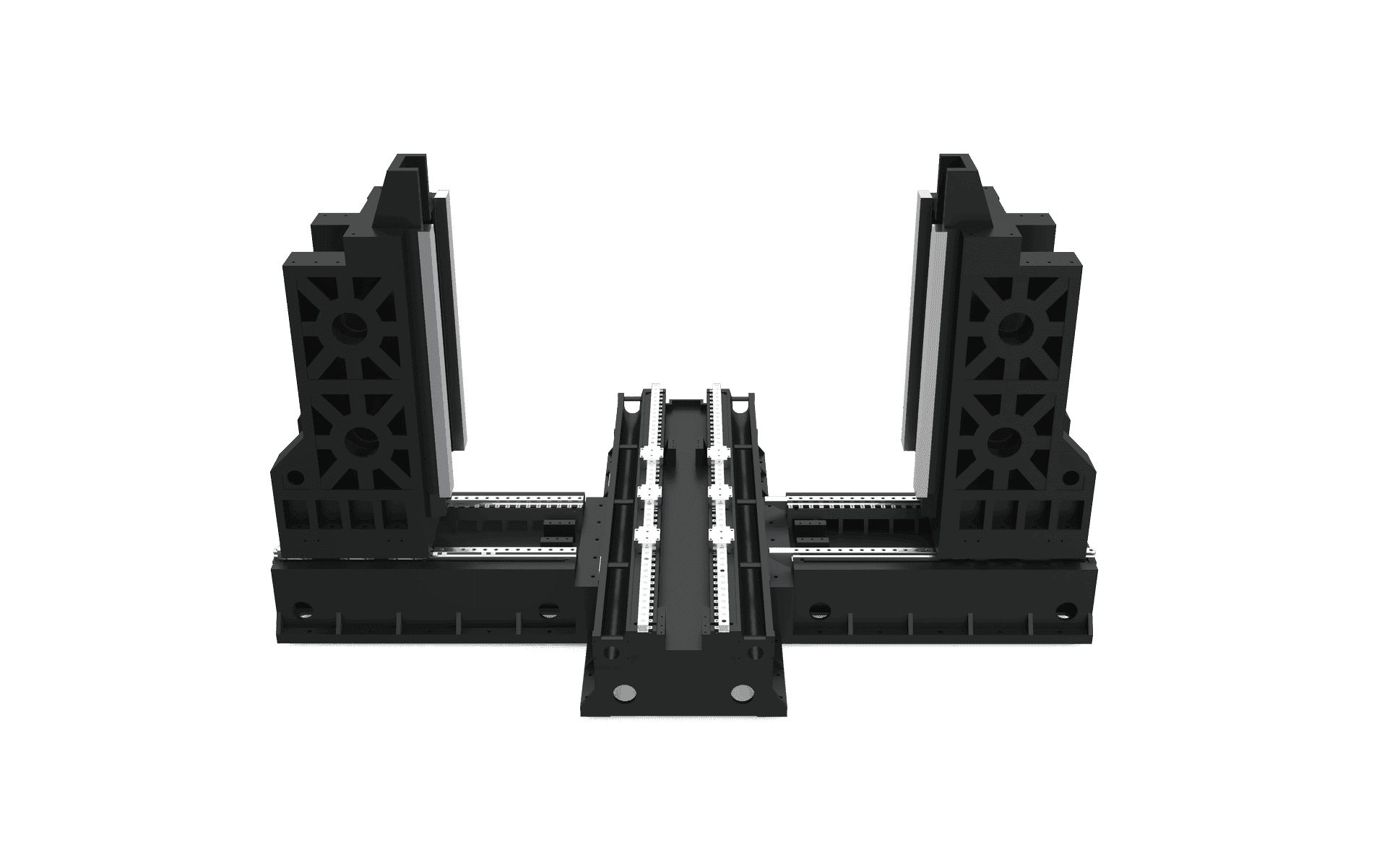

Casting

The bed is cast from HT300, and the internal ribs are reinforced and subjected to secondary annealing and aging treatment. High stability and not easy to deform. Large-span base effectively disperses gravity and processing endurance.

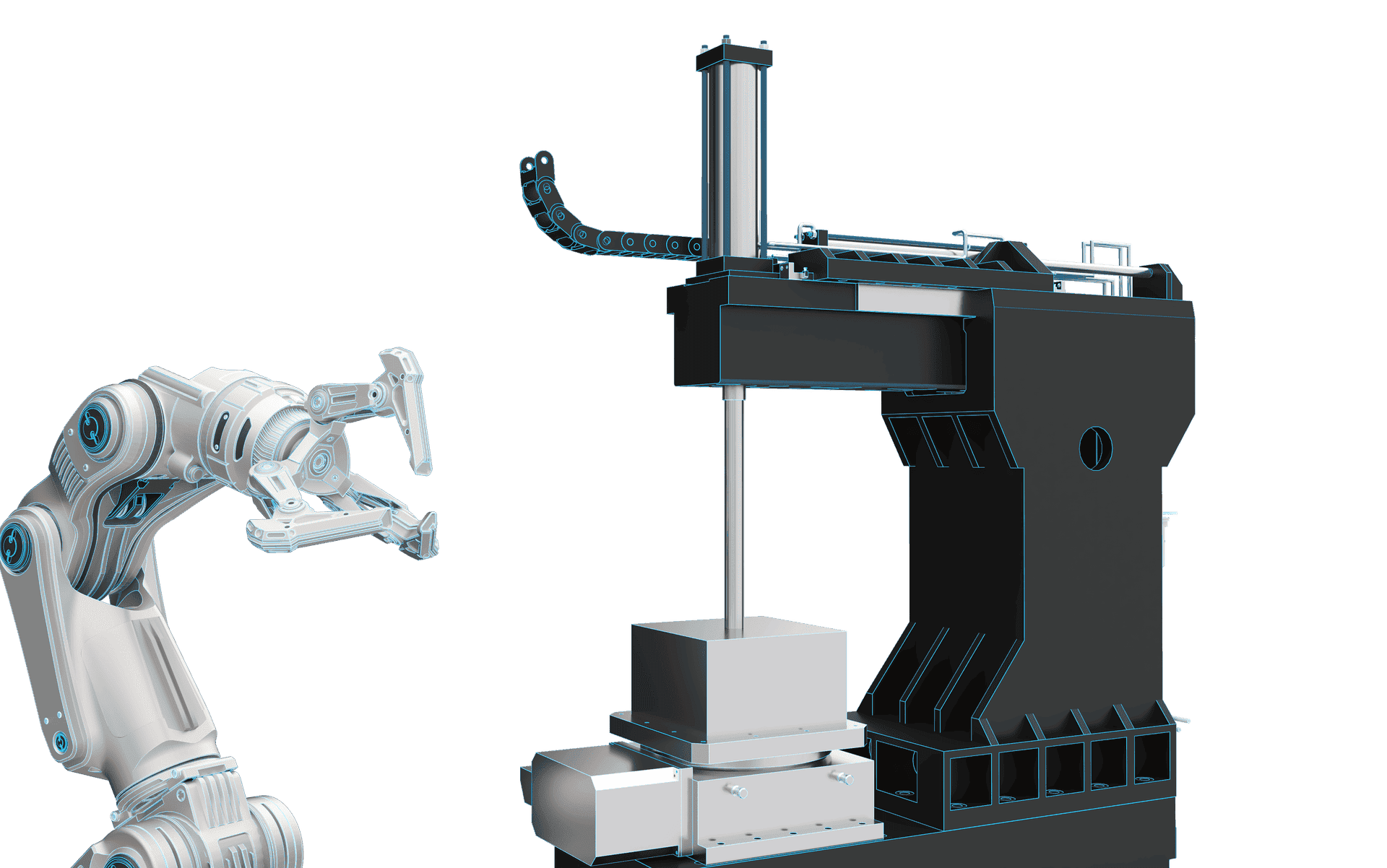

Assisting equipments

The workpiece clamping adopts the telescopic pressing method. When loading, the pressing device automatically returns. Convenient for loading. After loading is completed, the pressing device automatically extends to press the workpiece tightly. Lt can be matched with a Fully automatic manipulator that realizes high-efficiency automated processing.

Double tool magazine

It has a double-tool magazine structure and is equipped with a high-speed automatic ATC tool-changing system. After one clamping, It can realize multi-process processing of milling, drilling, and tapping at one time, suitable for large and medium-sized, Multiple workstations for batch parts, and drilling. Drilling, and tapping in multiple coordinate directions at the same time. It can greatly improve production efficiency.

| Items | Value | Unit | ||||

| Feed speed | X/Y/Z maximum rapid feed rate | 8000 | mm/min | |||

| Processing capacity | Machine length | 600 | mm | |||

| Machine height | 600 | mm | ||||

| Cutting size | 550 | mm | ||||

| Worktable | Max. load capacity | 2000 | KG | |||

| Spindle | Spindle | Φ190 | / | |||

| Spindle motor | 2*18.5 | KW | ||||

| Tool holder specifations | BT50 | / | ||||

| Spindle speed | 50-500 | rpm | ||||

| Tapping(steel) | M12-M24 | / | ||||

| Drilling diameter | 10-20 | mm | ||||

| Max. cutting chip | 2*1.5 | mm | ||||

| Cutter diameter | Φ150 | mm | ||||

| The longest cutter | 280 | mm | ||||

| Motor power | X/Y/Z servo motor | 3/3/3/3/3/3 | KW | |||

| Accuracy | Squareness | 0.02 | mm/300mm | |||

| Accuracy for dimension | 0.05 | mm/300mm | ||||

| Tool magazine | ATC capacity | 24T | / | |||

| Space & weight | Machine weight | About 16000 | KG | |||

| Machine size (L*W*H) | 5563*4325*3207 | mm | ||||

Contact us for more information on our Custom Made Machine Tools Solutions for complex workpieces. When you need high rigidity, efficiency and powerful machines,GooDa Machinery gets you going!

To meet your different processing needs, we provide three widely used systems on the market for you to choose.

Mitsubishi

Programming language: Mainly uses G code, supports MELDAS programming. Compatibility: Compatible with many automation devices, suitable for integration.

Fanuc

Programming language: Widely uses G code and macro programming, supports Fanuc proprietary language. Compatibility: Highly compatible, suitable for a variety of machine tools and equipment.

Siemens

Programming language: Uses G code, supports ShopMill/ShopTurn with advanced functions. Compatibility: Highly integrated with other Siemens systems, suitable for complex manufacturing environments.Our relationship with clients doesn't end with the sale. We offer comprehensive after-sales support that encompasses everything from expert installation services to hands-on training sessions, ensuring your team is fully equipped to operate and maintain our machinery. Our responsive customer service and technical support are always at your disposal, providing solutions and assistance to keep your operations running smoothly