VM-2340

CNC Gantry Milling Machine

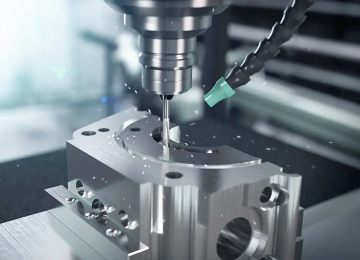

Process capacity:1800*4000mm. Gear box type spindles with high torque spindle motors.

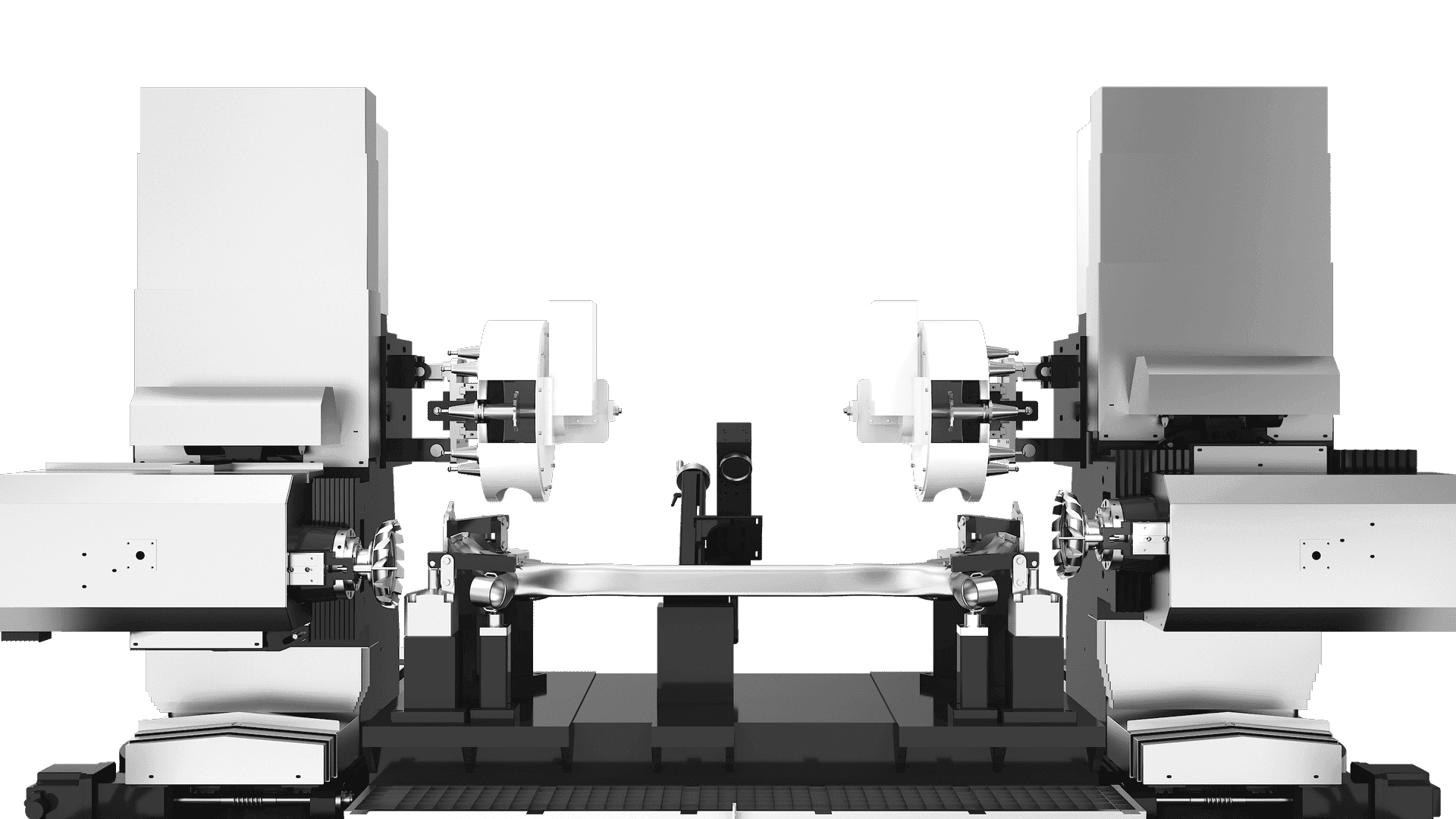

The dual horizontal machining center adopts a composite dual-channel system control and mechanical spindle, which can meet the large torque cutting and high processing efficiency. The overall machine runs smoothly.

Composite dual channel system

Adopting composite dual-channel system control, while simultaneously processing the same features on both ends of the workpiece, it can also process workpieces with different features on both ends, two independent processing units, The application of this control system can bring great help to the production process, improve production efficiency, reduce failure rates, reduce production costs, and improve product quality to meet the diverse processing needs of customers.

Rapid positioning

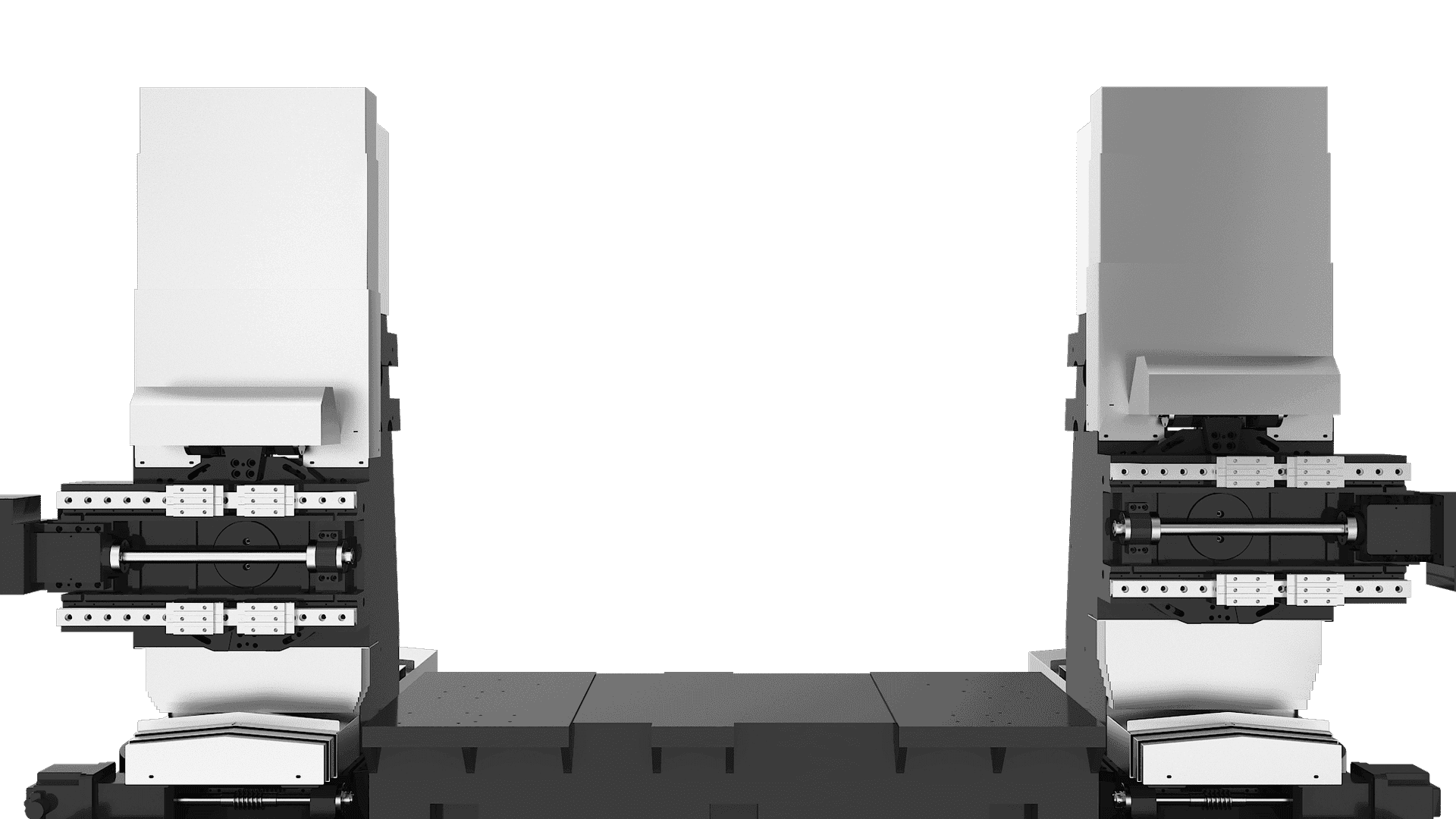

The X, Y, Z, and lead screws of the machine are all high-precision ball screws. The guide rail structure of the X, Y, and Z axes adopts heavy-duty roller guide rails, which are highly energy-efficient, precise positioning, and fast in response, achieving minimal vibration during machine feeding, and no creeping when feeding at low speed.

Dual Z-axis

It adopts a double Z-axis structure design, and the spindle part adopts a mechanical spindle, which can provide large torque cutting and high processing efficiency. And smooth overall operation of the machines.

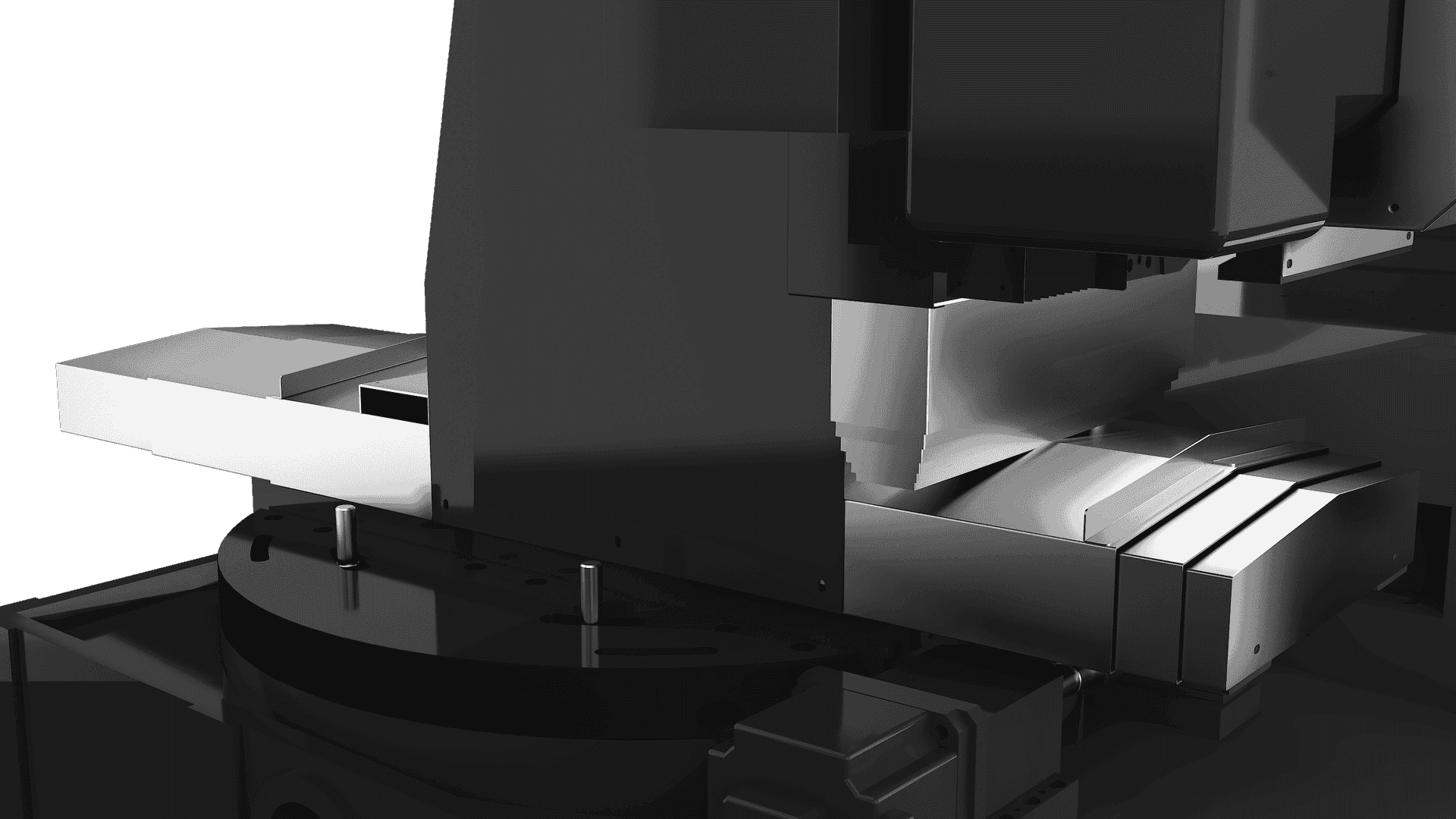

Machine protection

The machine guide rail adopts a special stainless steel guide rail protective cover, which has good sealing performance, is strong and durable, and runs smoothly. Extend the service life of machine guide rails and ensure the precision of machines. The electrical control cabinet is sealed dust-proof and air-conditioned for dehumidification to ensure the long-term stability of the electrical cabinet.

| Items | Value | Unit | ||||

| Travel | X-axis travel | 500 | mm | |||

| Y-axis travel | 500 | mm | ||||

| Z-axis travel | 300 | mm | ||||

| A/C axis | A-axis adjustable angle | ±3° | / | |||

| C-axis adjustable angle | ±3° | |||||

| Spindle | Tool holder specifications | BT50-150 | / | |||

| Spindle speed | 20-3000 | rpm | ||||

| Power | Spindle motor power | 7.5 | KW | |||

| Tool magazine | ATCcapacity | 8 | T | |||

| Tool change time | 8 | S | ||||

| Max.tool weight | 8 | KG | ||||

| Feed | X, Y, Z axis fast moving speed | 10/10/10 | m/min | |||

| Feed speed (MAX.) X/Y/Z | 8/8/8 | |||||

| Accuracy | Positioning accuracyGB/T 17421.2-2000 | 0.02/1000 | mm | |||

| Repeat positioning accuracyGB/T 17421.2-2000 | 0.015/1000 | |||||

| Source | Total machine power | 60 | KW | |||

| Air source | 6-8 | kg/cm² | ||||

| Size & weight | Machine space | 5980*3380*2850 | mm | |||

| Machine weight | 15 | T | ||||

Contact us for more information on our Custom Made Machine Tools Solutions for complex workpieces. When you need high rigidity, efficiency and powerful machines,GooDa Machinery gets you going!

To meet your different processing needs, we provide three widely used systems on the market for you to choose.

Mitsubishi

Programming language: Mainly uses G code, supports MELDAS programming. Compatibility: Compatible with many automation devices, suitable for integration.

Fanuc

Programming language: Widely uses G code and macro programming, supports Fanuc proprietary language. Compatibility: Highly compatible, suitable for a variety of machine tools and equipment.

Siemens

Programming language: Uses G code, supports ShopMill/ShopTurn with advanced functions. Compatibility: Highly integrated with other Siemens systems, suitable for complex manufacturing environments.Our relationship with clients doesn't end with the sale. We offer comprehensive after-sales support that encompasses everything from expert installation services to hands-on training sessions, ensuring your team is fully equipped to operate and maintain our machinery. Our responsive customer service and technical support are always at your disposal, providing solutions and assistance to keep your operations running smoothly