After-Sales Guarantee

Our commitment to clients extends well beyond the purchase of CNC accessories. We provide comprehensive after-sales support, including expert installation guidance and hands-on training sessions, to ensure your team is fully prepared to use and maintain our products effectively. Our dedicated customer service and technical support teams are always available to assist you, offering solutions and advice to ensure your operations remain efficient and uninterrupted.

-

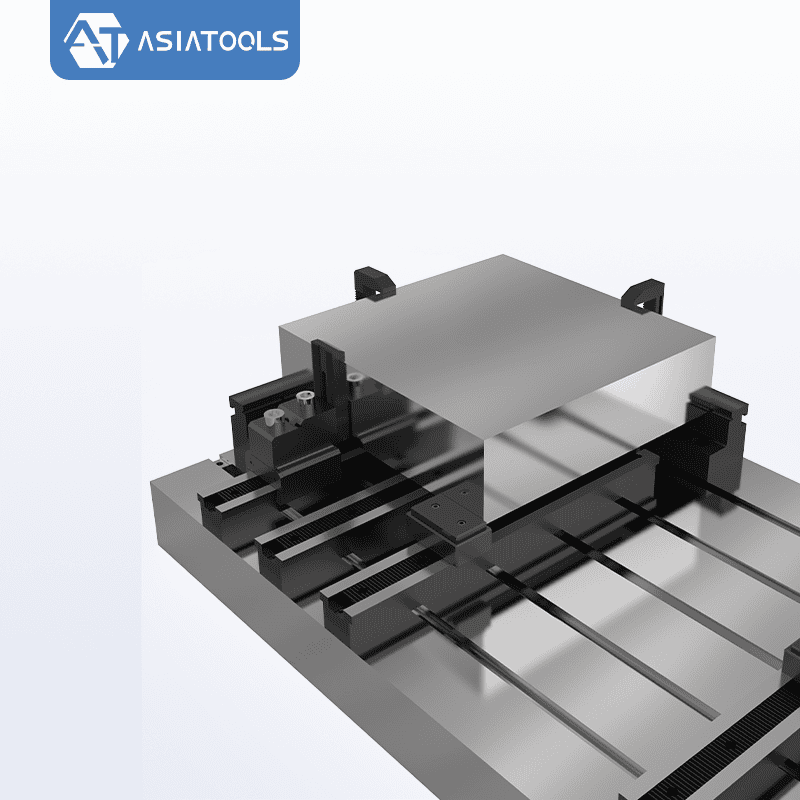

Q: What is a CNC milling fixture?

A: A CNC milling fixture is a tool used to securely hold a workpiece in place during the milling process. It ensures the workpiece remains in the correct position and orientation while being machined.

-

Q: Why are fixtures important in CNC milling?

A: Fixtures are crucial because they provide stability and precision. By holding the workpiece securely, they help achieve accurate and repeatable results, reduce errors, and enhance safety during machining operations.

-

Q: How do you choose the right fixture for a CNC milling operation?

A: Choosing the right fixture depends on several factors, including the size and shape of the workpiece, the type of milling operation, the precision required, and the production volume. It's essential to select a fixture that can accommodate these needs while ensuring stability and ease of use.

-

Q: What are the different types of CNC milling fixtures?

A: There are several types of fixtures, including modular fixtures, dedicated fixtures, hydraulic fixtures, and pneumatic fixtures. Each type has its specific applications and advantages, such as flexibility, ease of use, or high clamping force.

-

Q: Can fixtures be customized for specific applications?

A: Yes, fixtures can be custom-designed to meet specific requirements of a particular workpiece or machining process. Custom fixtures are often used when standard solutions do not provide the necessary precision or efficiency.

-

Q: What are the maintenance requirements for CNC milling fixtures?

A: Regular maintenance involves cleaning the fixture to remove debris, checking for wear and tear, lubricating moving parts, and ensuring all components are functioning correctly. Proper maintenance helps extend the life of the fixture and maintain its performance.