VM-2340

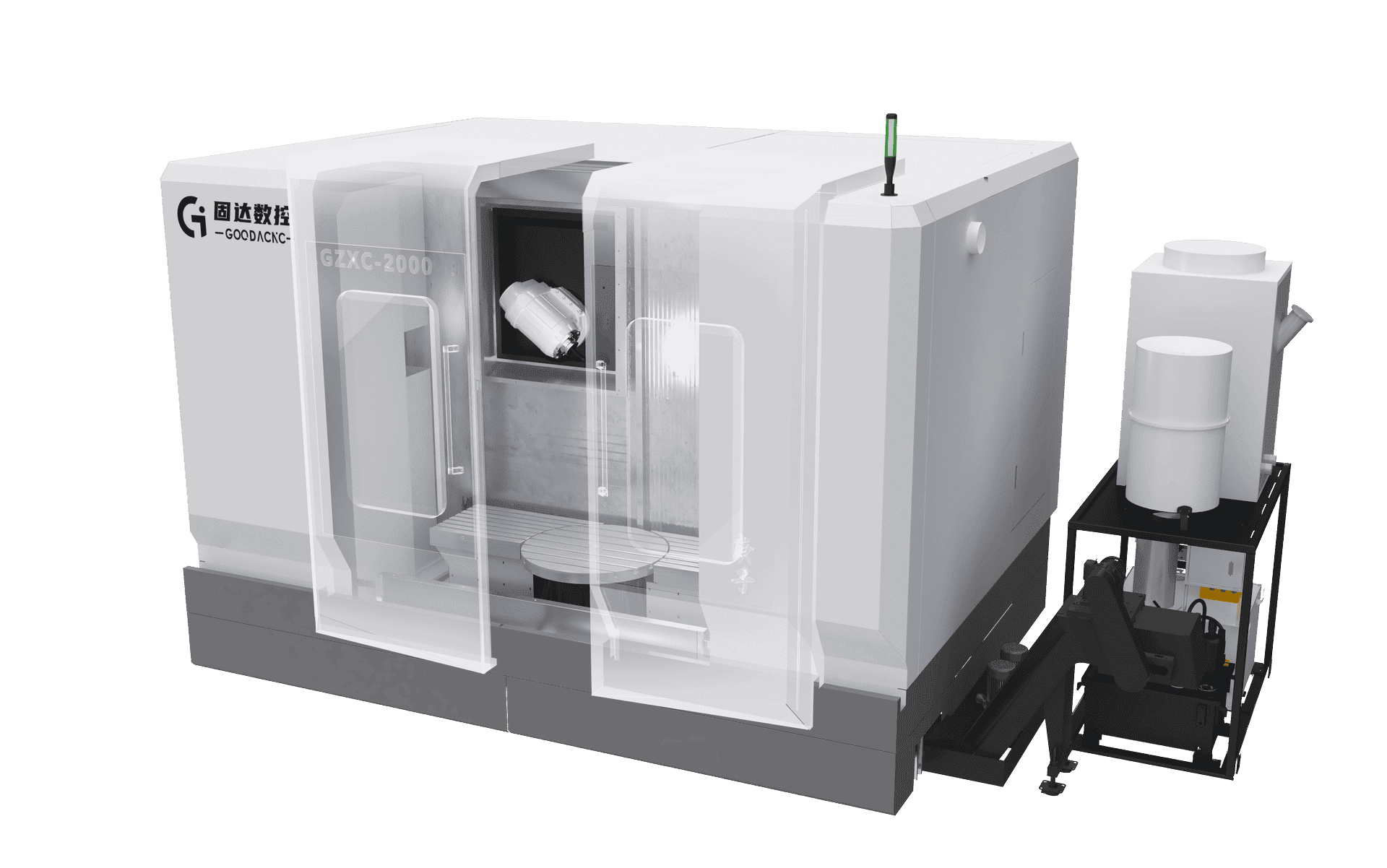

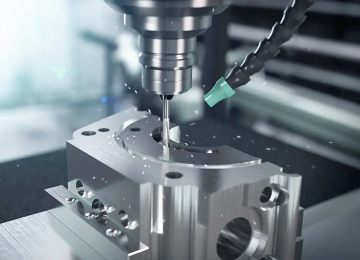

CNC Gantry Milling Machine

Process capacity:1800*4000mm. Gear box type spindles with high torque spindle motors.

The 5-axis multi-tasking machining center comes with a fully digital numerical control device. Integrated with artificial intelligence technology. It includes features such as statistics of screw load in full-lifecycle, intelligent management of tool service life, machine protection functions, QR codes, and self-adjustment of servo parameters, to enhance processing quality, optimize process parameters, and ensure equipment lifespan. It is suitable for fields such as aerospace, automotive, energy, shipbuilding, machine tools, molds, and 3C industries.

Spindle external coolant system

By circulating cooling water with temperature control in the outer cylinder of the spindle bearing part, it suppresses the deformation of the spindle due to the heat generated when it rotates at a high speed, thereby preventing changes in machining accuracy.

Mechanical spindle

The flow of cooling water is managed through strict temperature control in the shaft, which can suppress the heating of the ball screw and the thermal influence from the servo motor.

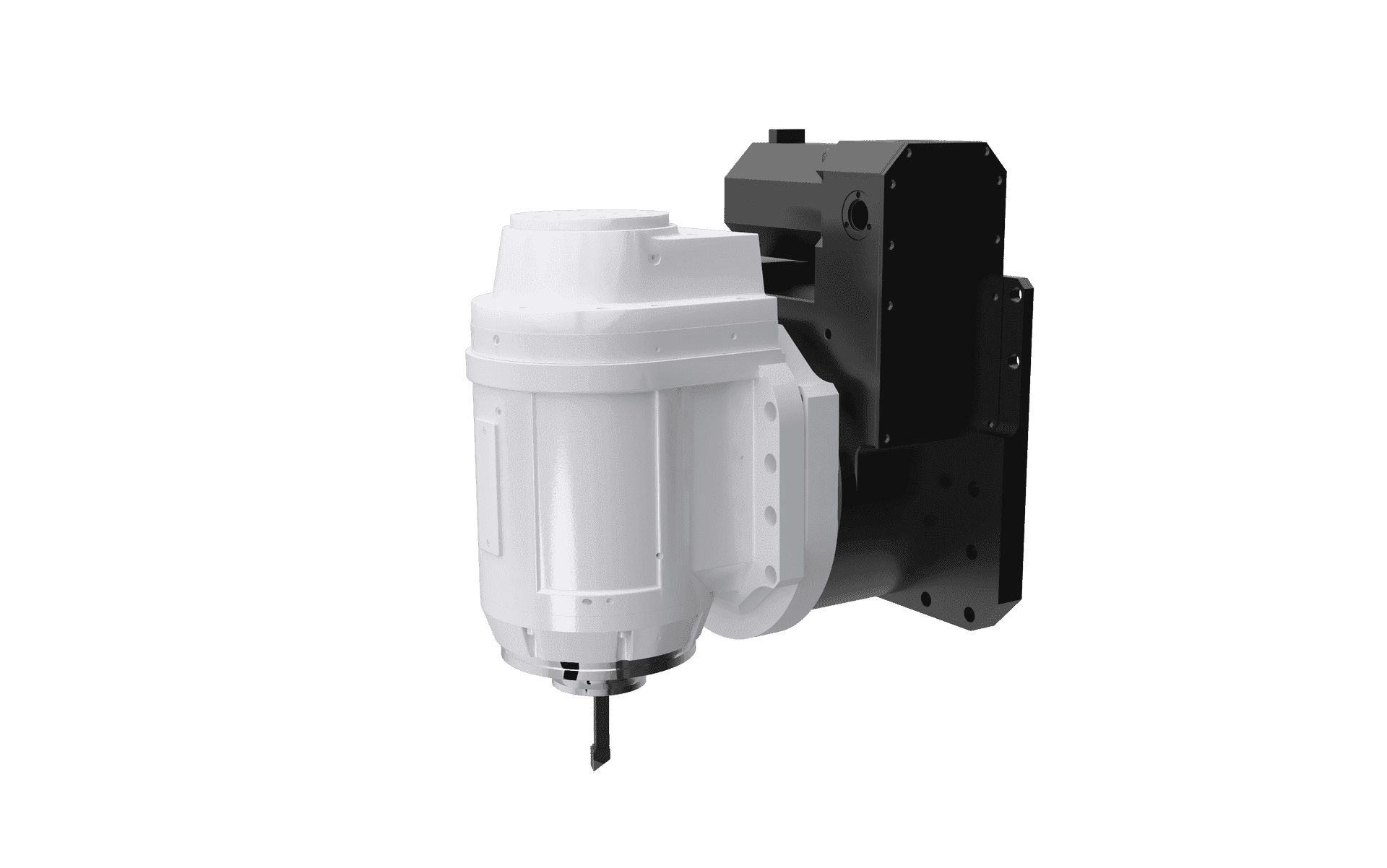

Milling & lathe integrated spindle

It supports the milling & lathe-integrated spindle unit matching the ATC reducer. The compact design is used to reduce interference, and the processing range has also been expanded.

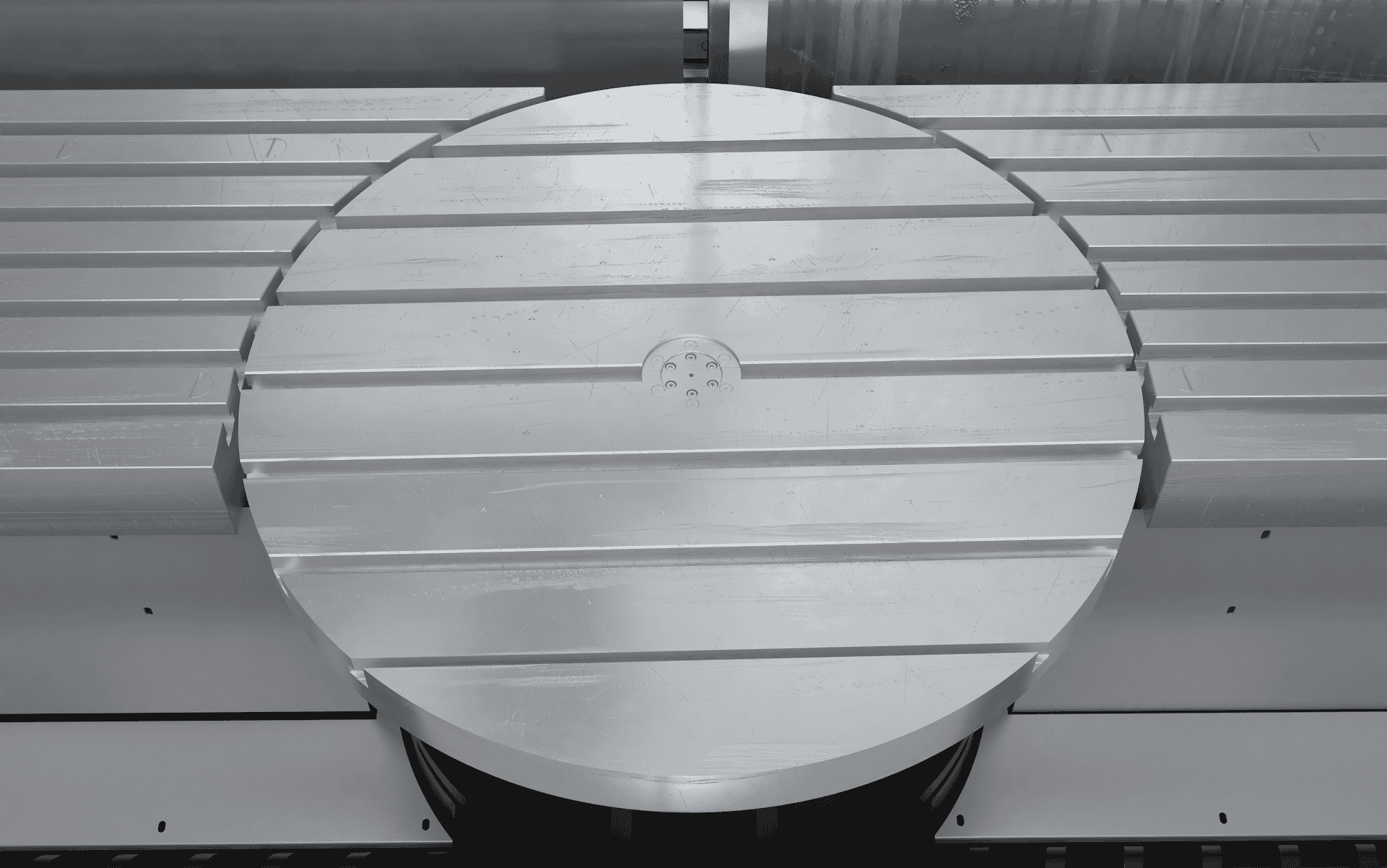

Circular grating

B and C axes are selected circular grating, to ensure the accuracy of the angular position information and improve the position accuracy of the rotary axis.

| Items | Value | Unit | ||||

| Fixed worktable | Worktable size | 2000*500 | mm | |||

| Max. load capacity | 1500 | KG | ||||

| T-slot | 7-20*63 | / | ||||

| X/Y/Z-axis | X-axis travel | 1800 | mm | |||

| Y-axis travel | 500 | |||||

| Z-axis travel | 600 | |||||

| Rapid traverse speed(X/Y/X) | 20/20/20 | mm/min | ||||

| Feed rate | 16/16/16 | |||||

| Positioning accuracy | 0.015/1000 | mm | ||||

| Repeat positioning accuracy | 0.01/1000 | |||||

| Turntable | Outer diameter | 800 | mm | |||

| Max. load | 850 | KG | ||||

| T-slot | 7*18*100 | mm | ||||

| Min. speed/Max. speed | 60/100 | rpm/min | ||||

| Positioning accuracy | ±7 | arc-sec | ||||

| Repeat positioning accuracy | ±5 | |||||

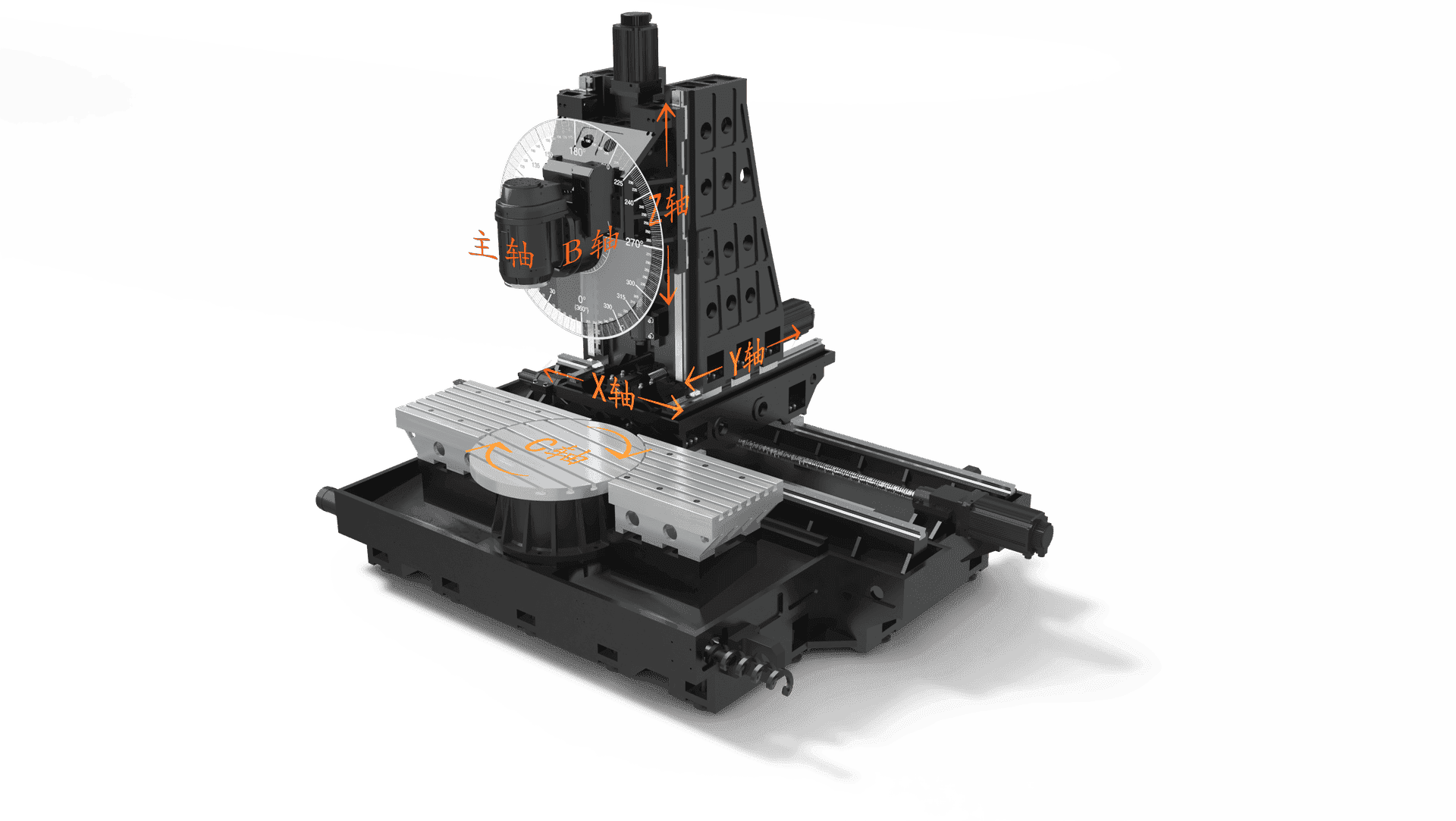

| B-axis | B-axis travel | -30°~+210° | ° | |||

| B-axis speed | 500 | rpm/min | ||||

| Positioning accuracy | 6 | sec | ||||

| Repeat positioning accuracy | -30~210° | |||||

| Spindle | Tool holder specifations | HSK-63A | / | |||

| Distance from spindle nose to table | 150 | mm | ||||

| Spindle speed(MAX.) | 45~12000 | r/min | ||||

| Tool magazine parameters | ATC capacity | 40 | T | |||

| Tool size(full tool)*tool length | ∅125*300 | mm | ||||

| Tool Dia(adjacent empty)*tool length | ∅220*300 | |||||

| Max. tool weight | 8 | KG | ||||

| Power requirement | Rated voltage | AC380V±10% | V | |||

| Total power | 80 | KW | ||||

| Air pressure | 0.6-0.7 | Mpa | ||||

| Space & weight | Machine weight | 18 | T | |||

| Maching size (L*W*H) | 7400*4400*3000 | mm | ||||

Contact us for more information on our Custom Made Machine Tools Solutions for complex workpieces. When you need high rigidity, efficiency and powerful machines,GooDa Machinery gets you going!

To meet your different processing needs, we provide three widely used systems on the market for you to choose.

Mitsubishi

Programming language: Mainly uses G code, supports MELDAS programming. Compatibility: Compatible with many automation devices, suitable for integration.

Fanuc

Programming language: Widely uses G code and macro programming, supports Fanuc proprietary language. Compatibility: Highly compatible, suitable for a variety of machine tools and equipment.

Siemens

Programming language: Uses G code, supports ShopMill/ShopTurn with advanced functions. Compatibility: Highly integrated with other Siemens systems, suitable for complex manufacturing environments.Our relationship with clients doesn't end with the sale. We offer comprehensive after-sales support that encompasses everything from expert installation services to hands-on training sessions, ensuring your team is fully equipped to operate and maintain our machinery. Our responsive customer service and technical support are always at your disposal, providing solutions and assistance to keep your operations running smoothly