VM-2340

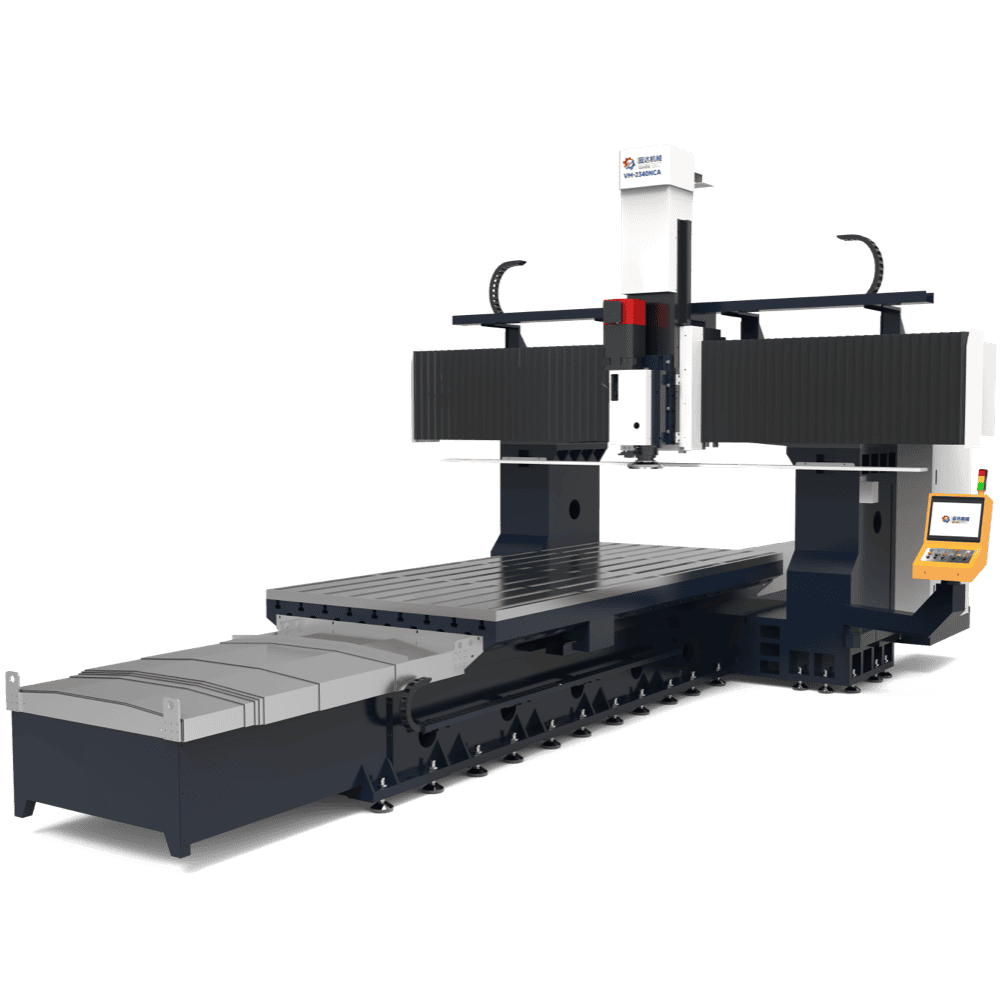

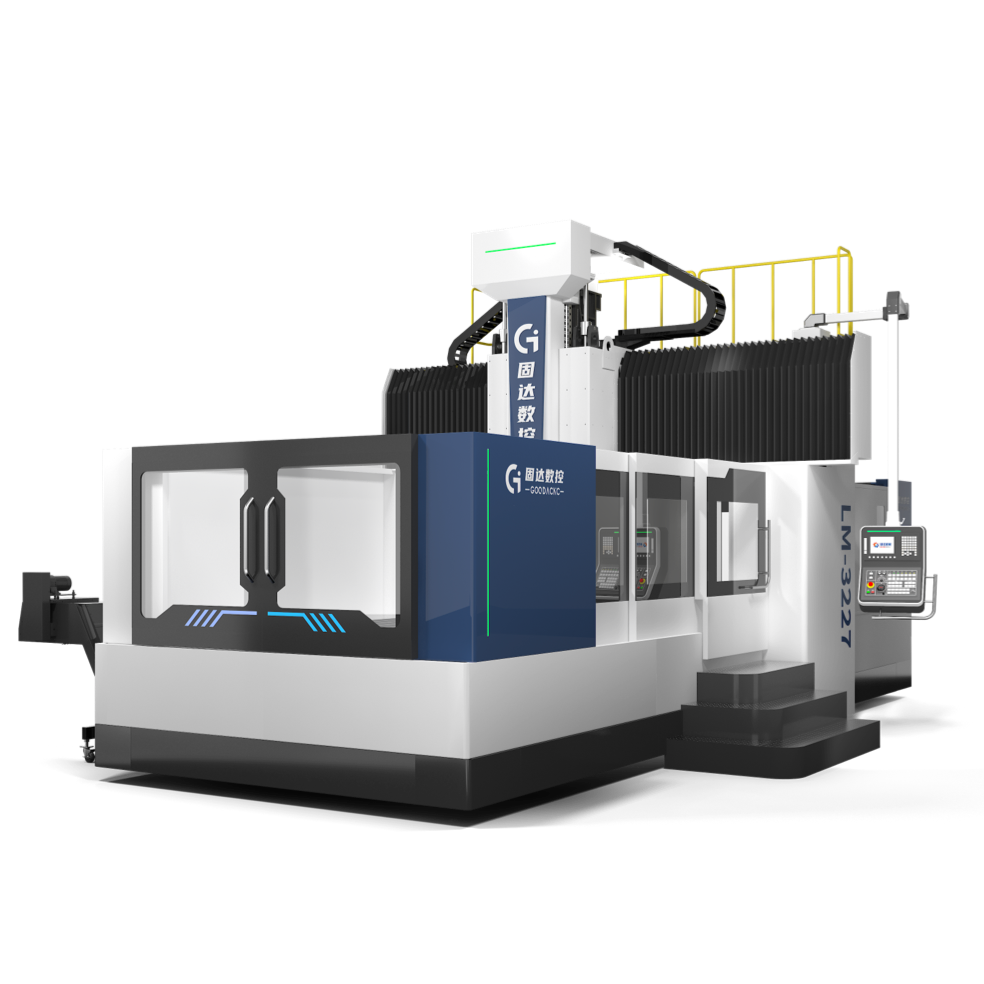

CNC Gantry Milling Machine

Process capacity:1800*4000mm. Gear box type spindles with high torque spindle motors.

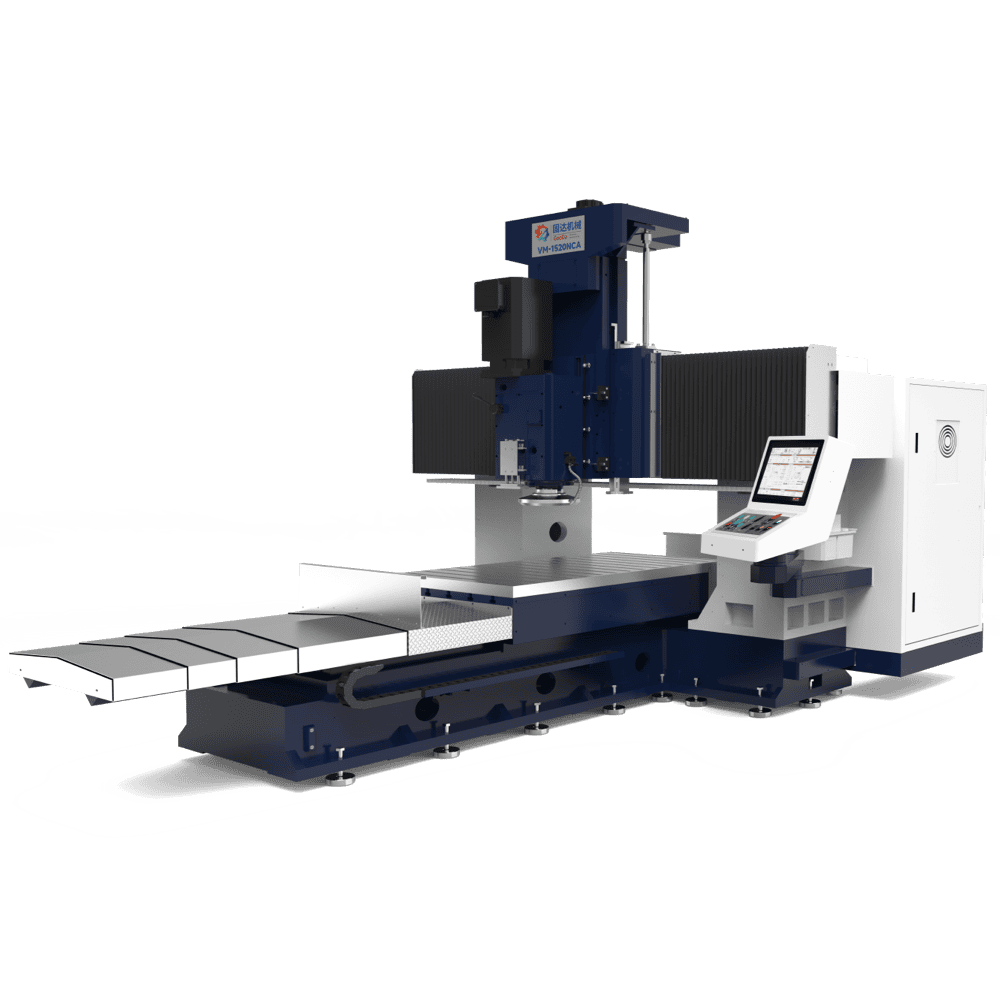

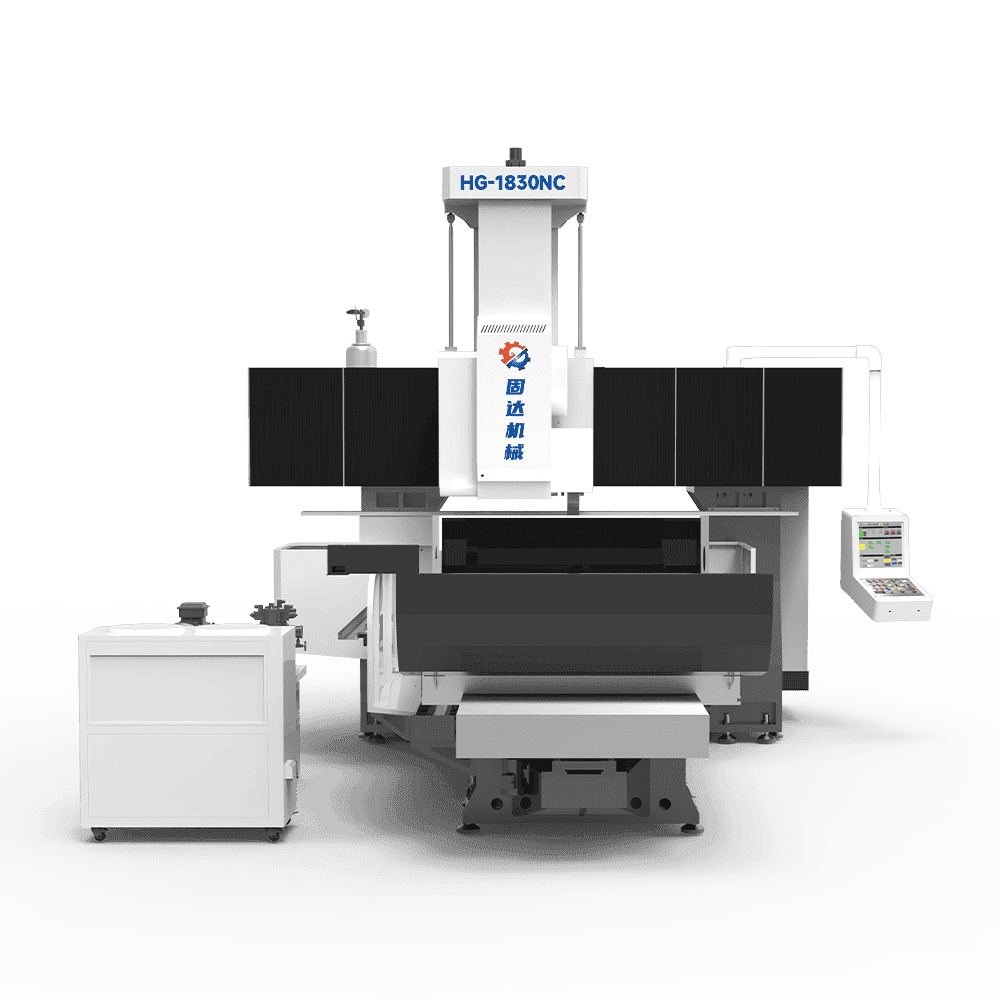

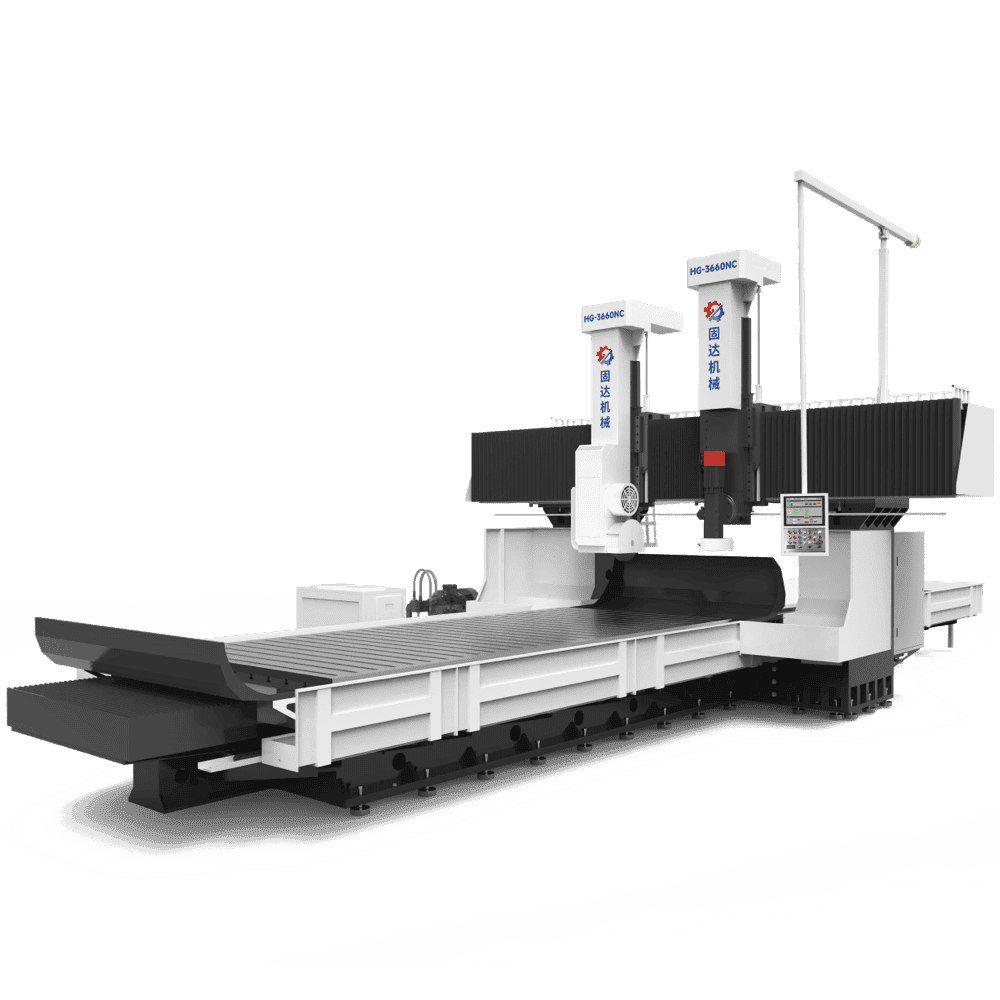

CNC Gantry Milling Machine

Process capacity:1800*4000mm. Gear box type spindles with high torque spindle motors.

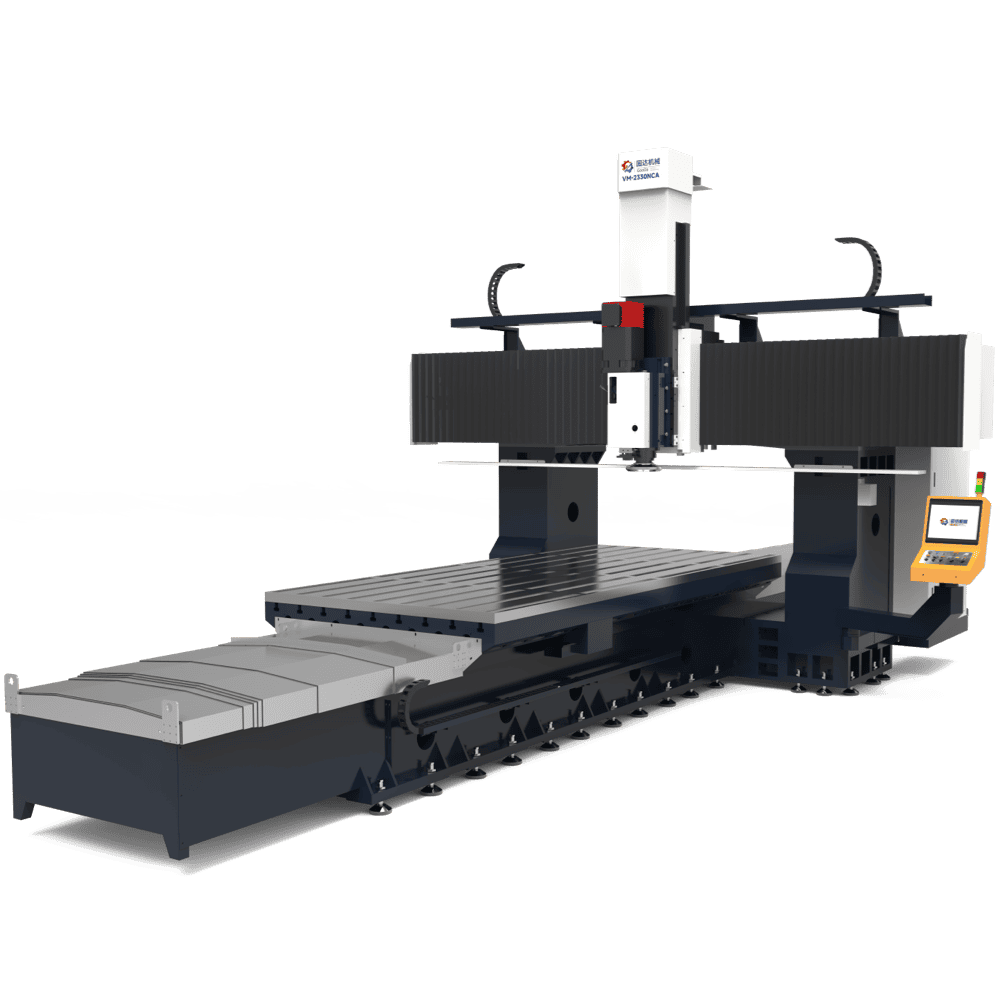

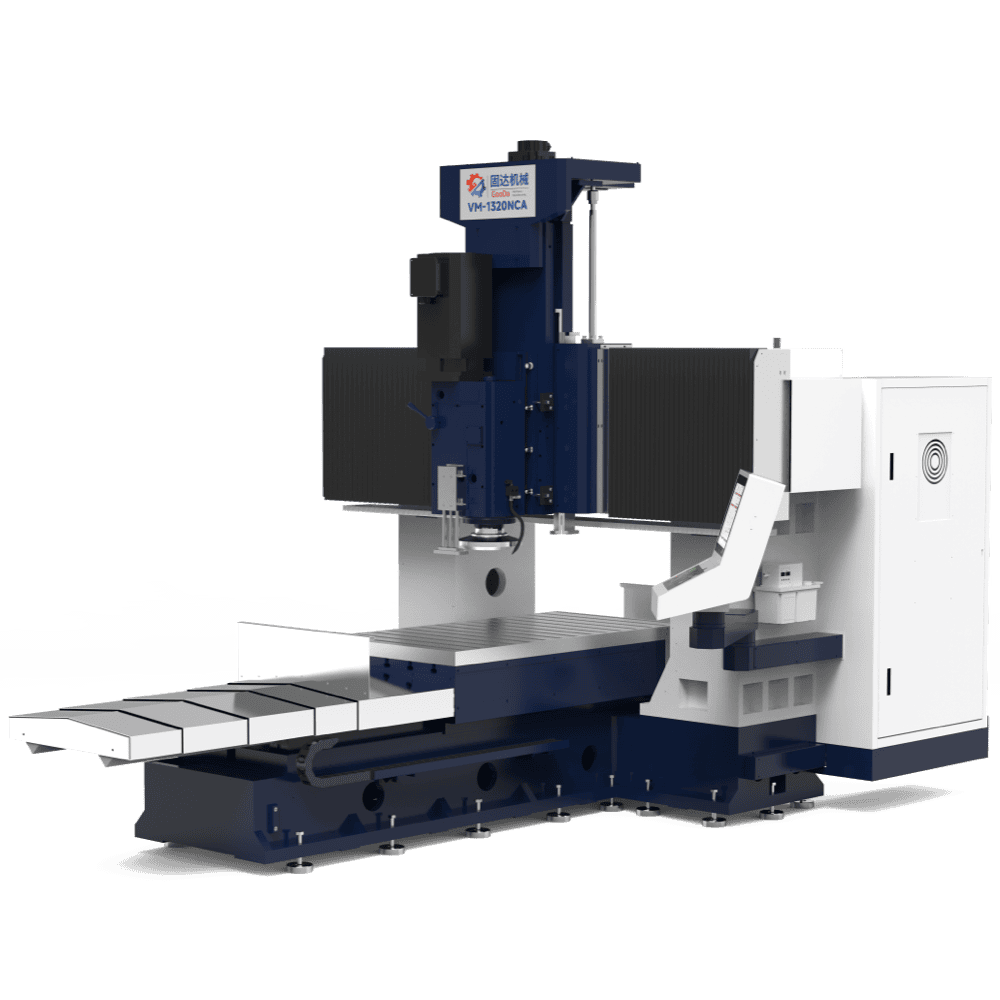

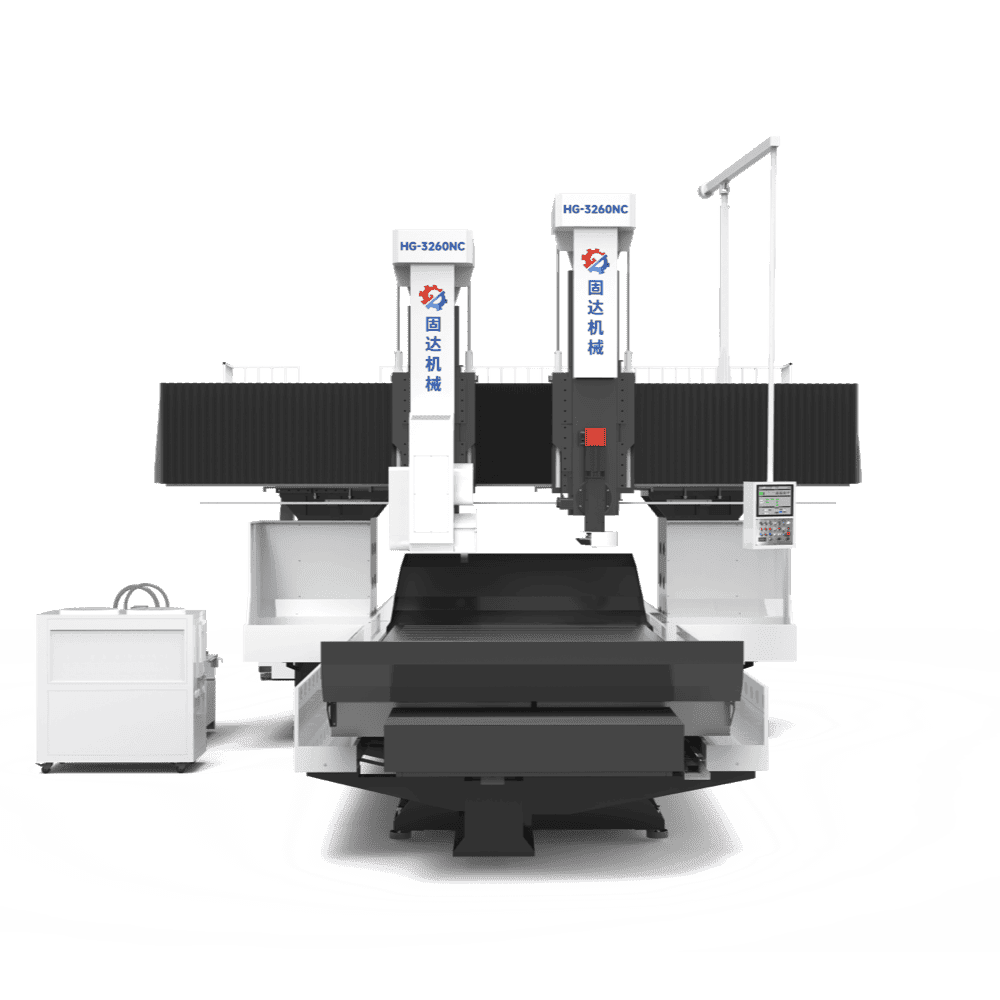

CNC Gantry Milling Machine

Process capacity:1800*3000mm. Gear box type spindles with high torque spindle motors.

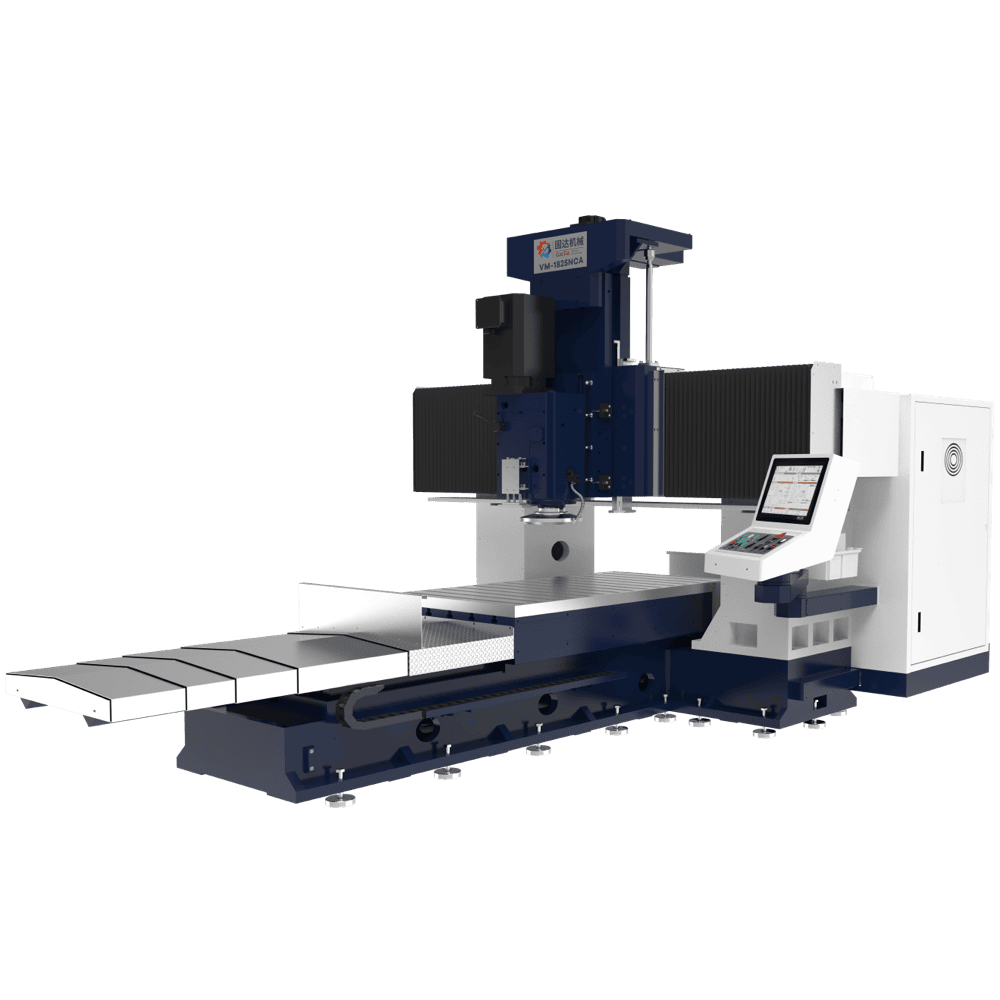

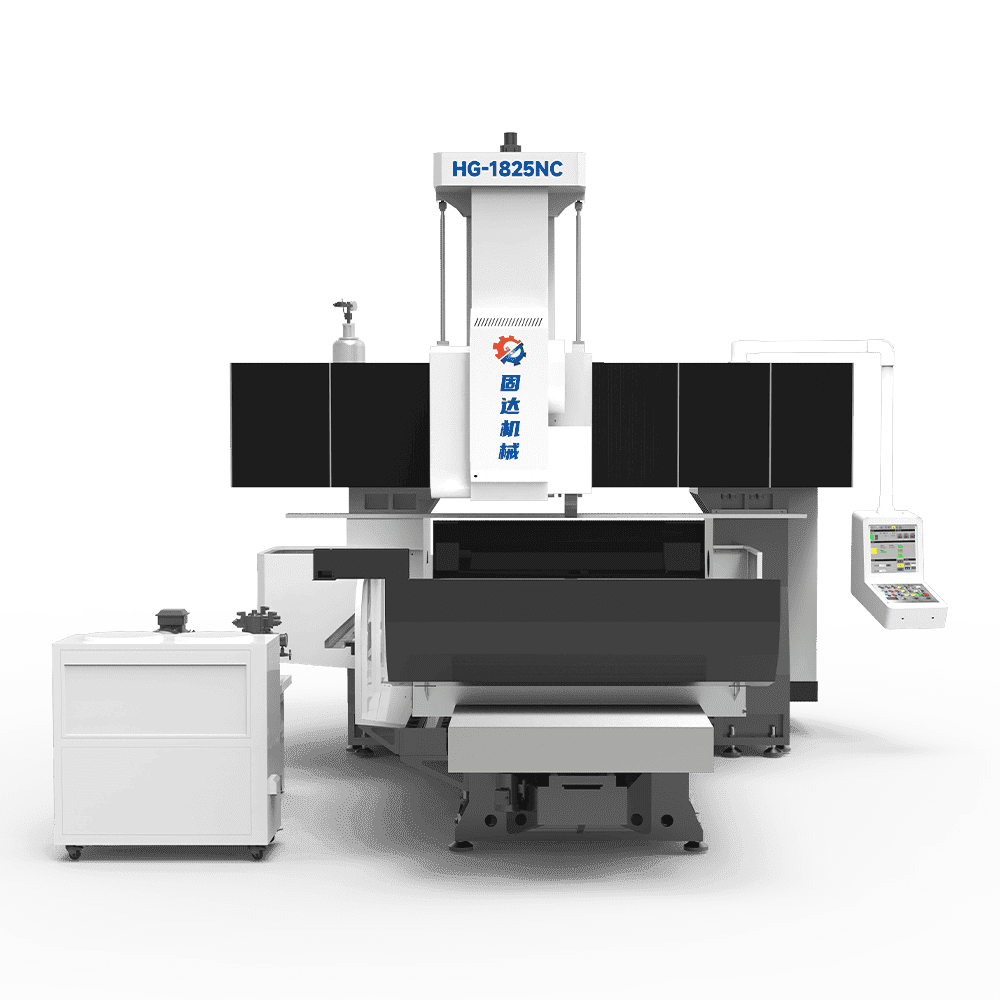

CNC Gantry Milling Machine

Process capacity:1400*2500mm. Gear box type spindles with high torque spindle motors.

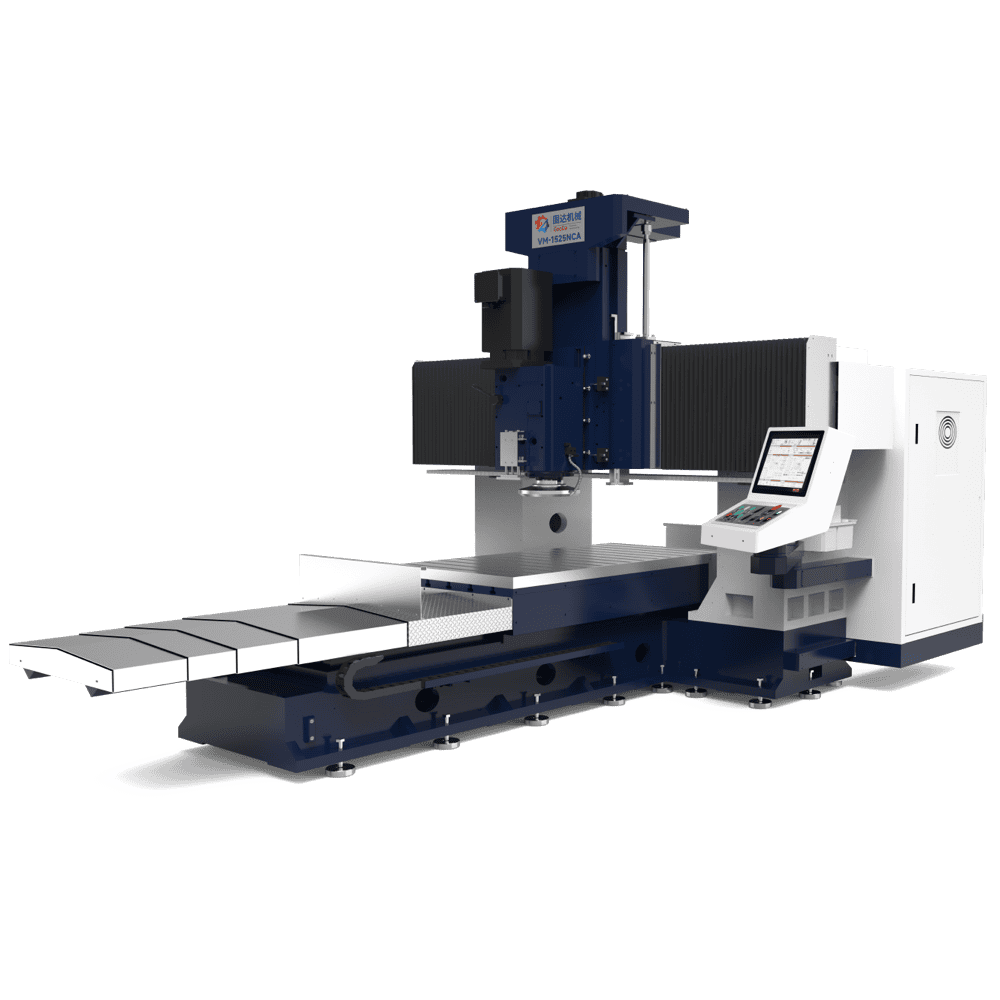

CNC Gantry Milling Machine

Process capacity:1200*2500mm. Gear box type spindles with high torque spindle motors.

CNC Gantry Milling Machine

Process capacity:1200*2000mm. Gear box type spindles with high torque spindle motors.

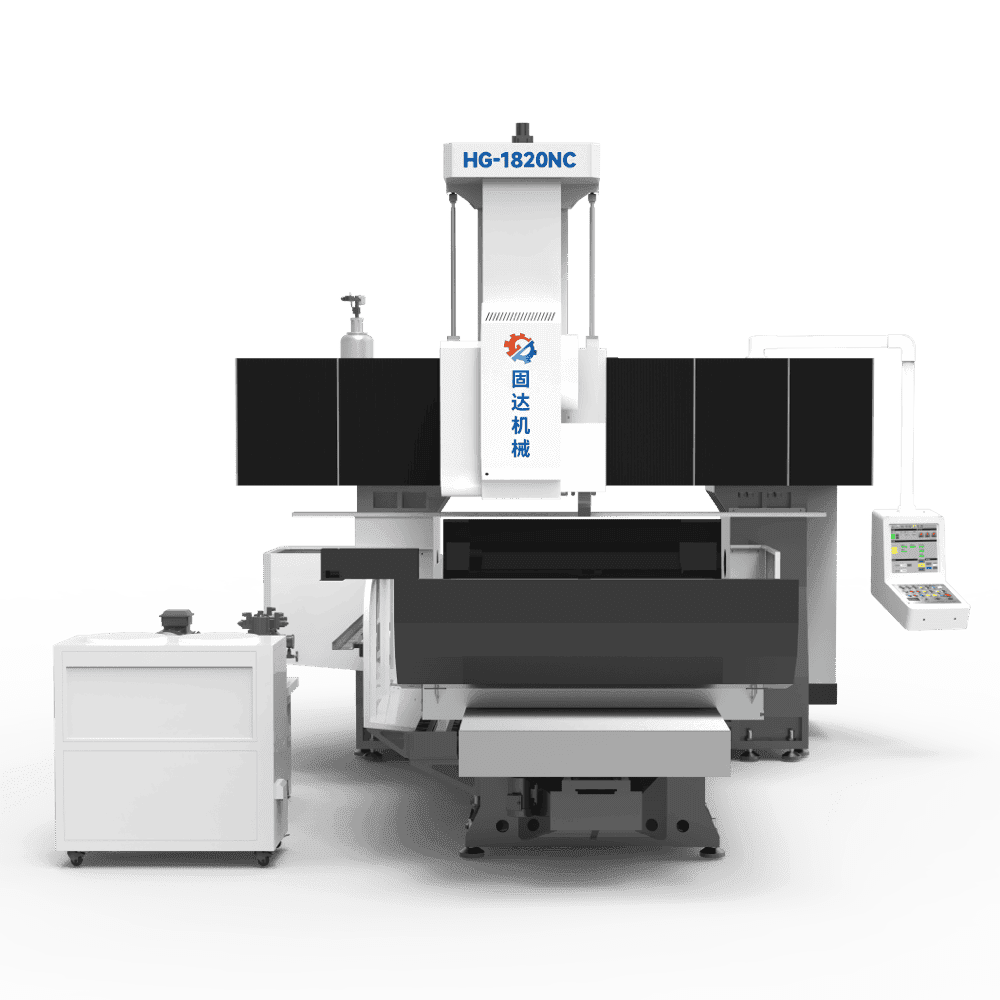

CNC Gantry Milling Machine

Process capacity:1200*2000mm. Gear box type spindles with high torque spindle motors.

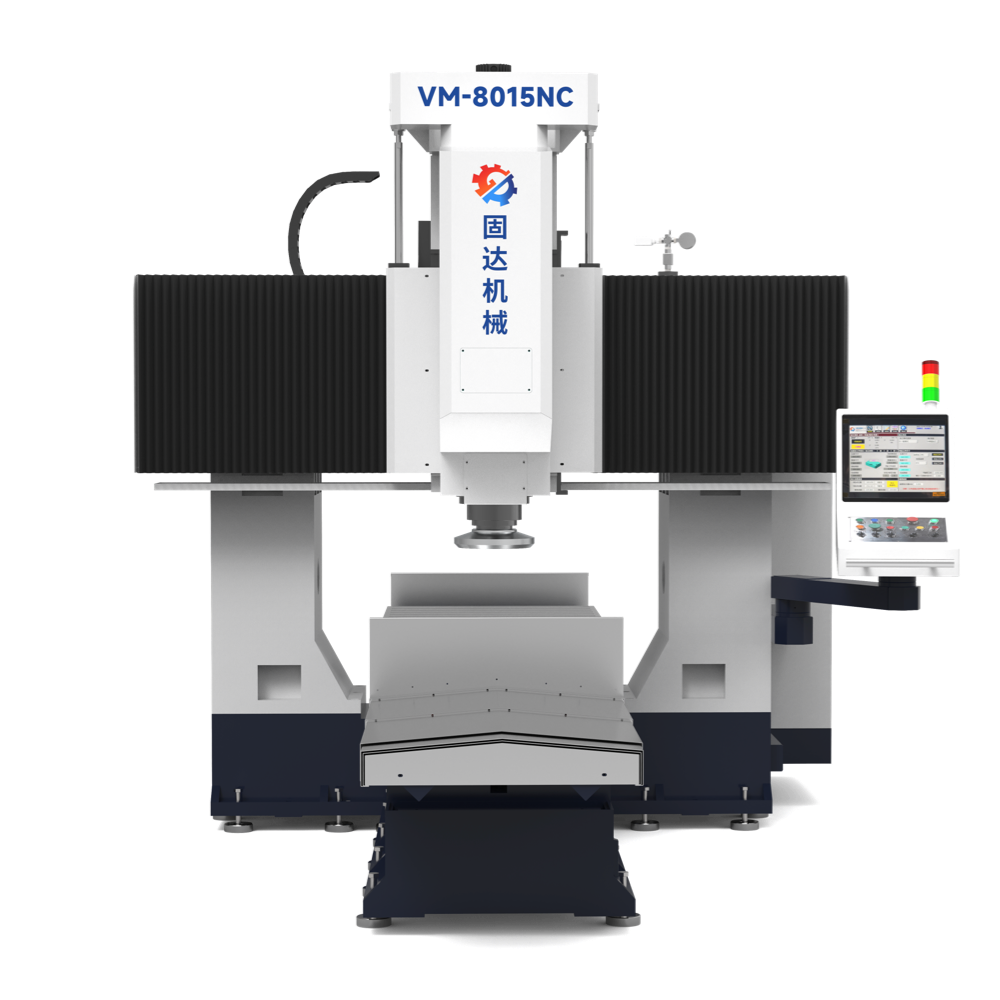

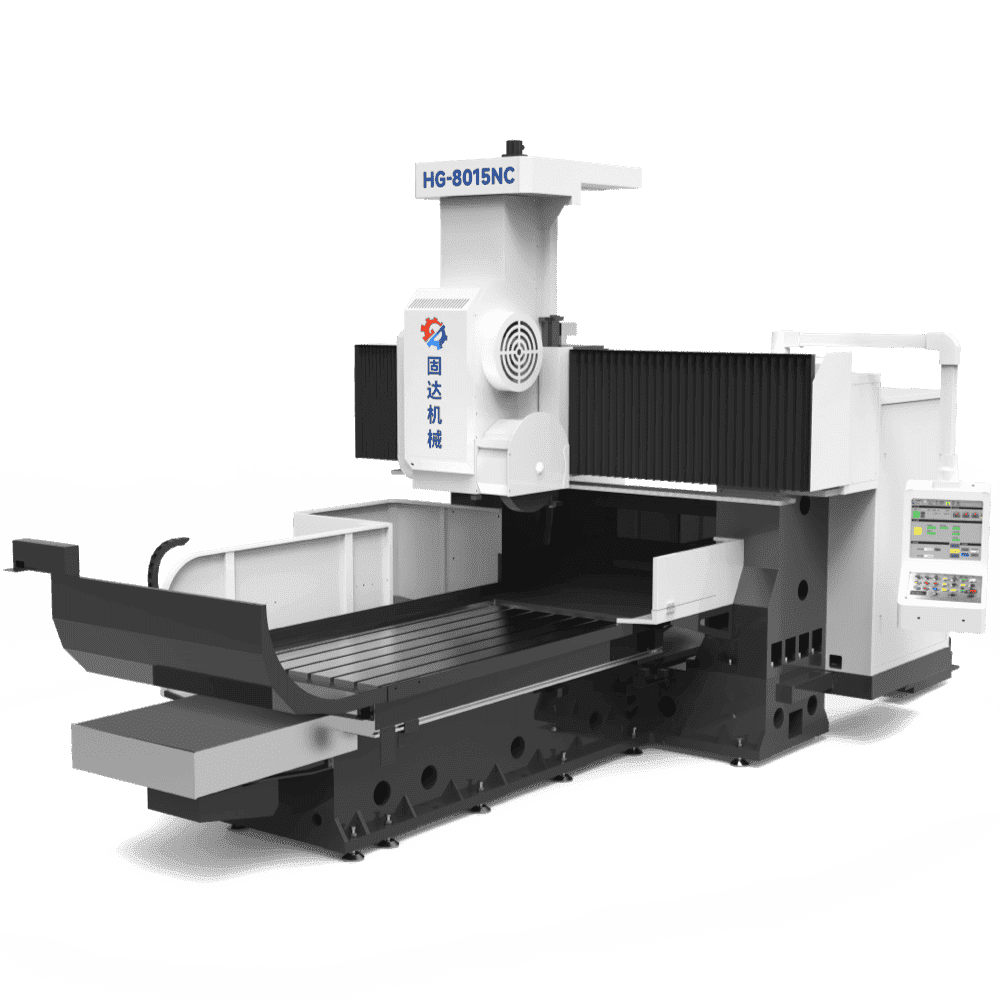

CNC Gantry Milling Machine

Process capacity:800*1500mm. Gear box type spindles with high torque spindle motors.

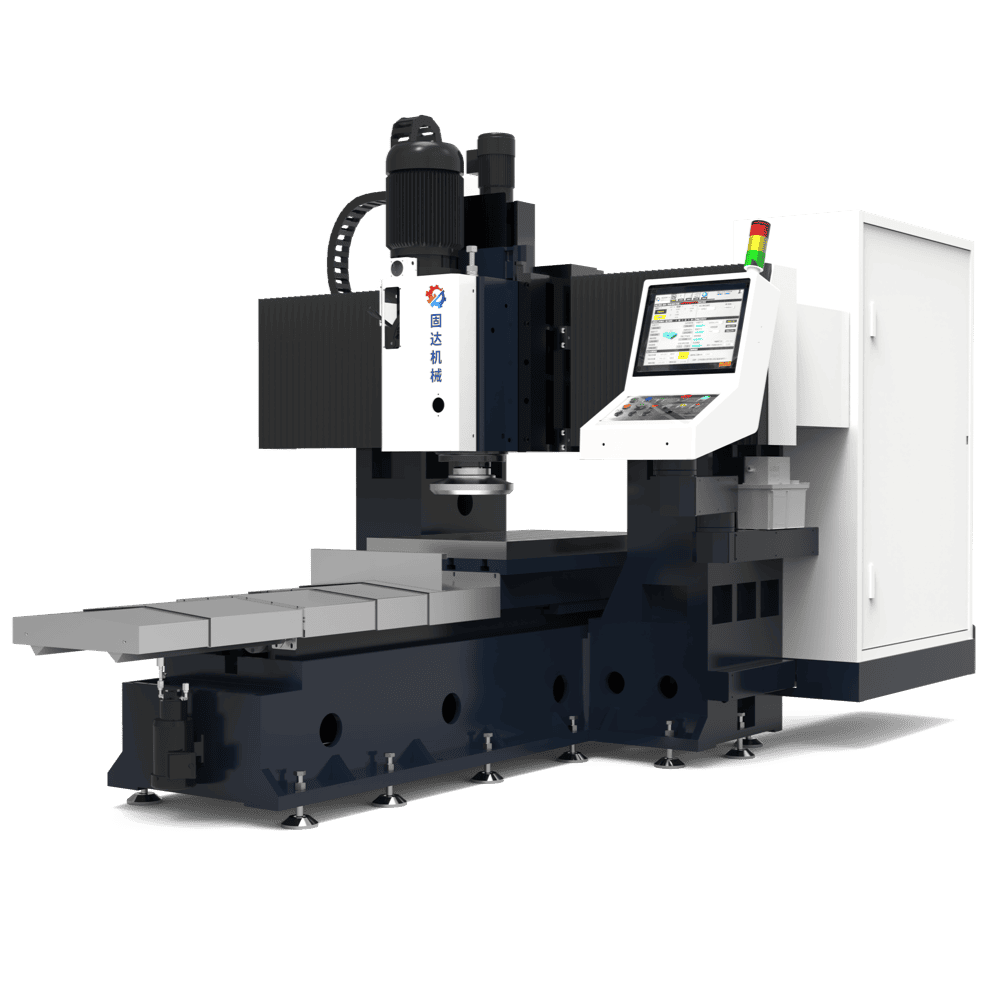

CNC Gantry Milling Machine

Process capacity:600*1000mm. Gear box type spindles with high torque spindle motors.

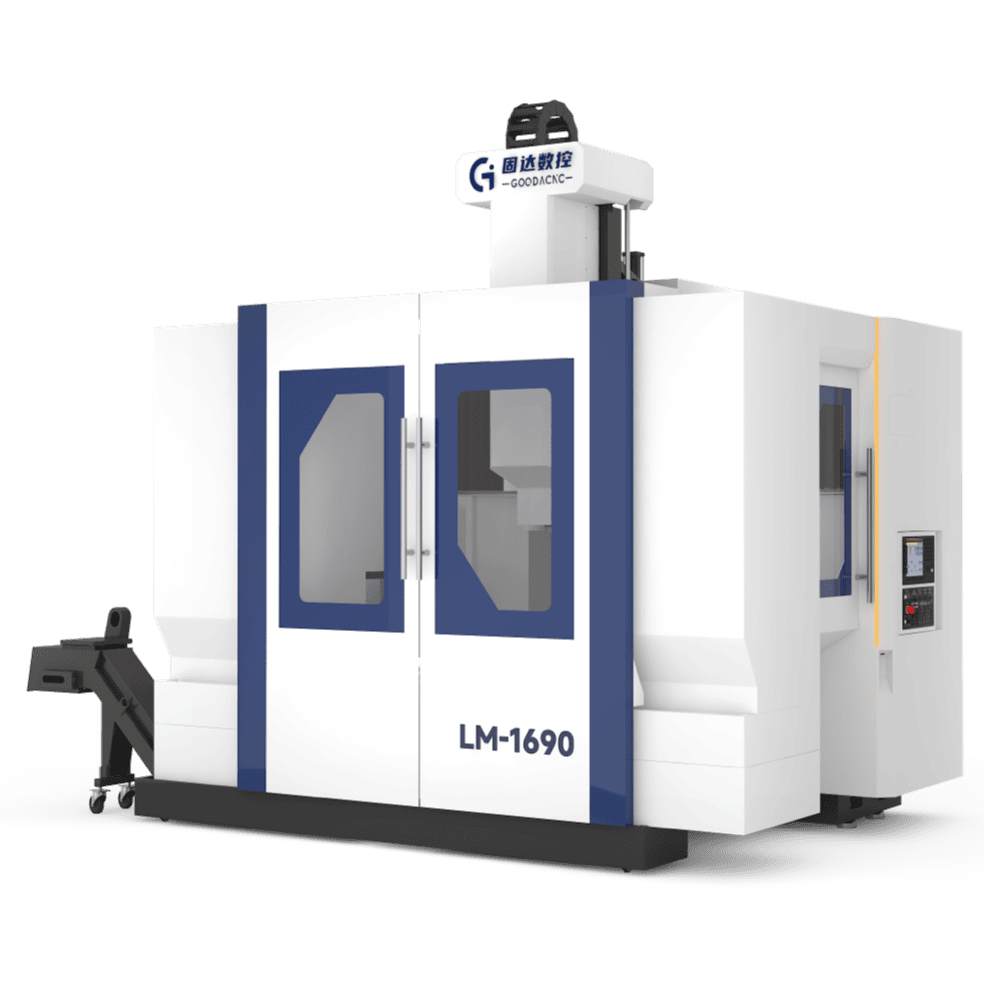

CNC Vertical Milling Machine

Process capacity:1000*600mm One-timedata setting, automatic positioning & measurement,automatic processing.

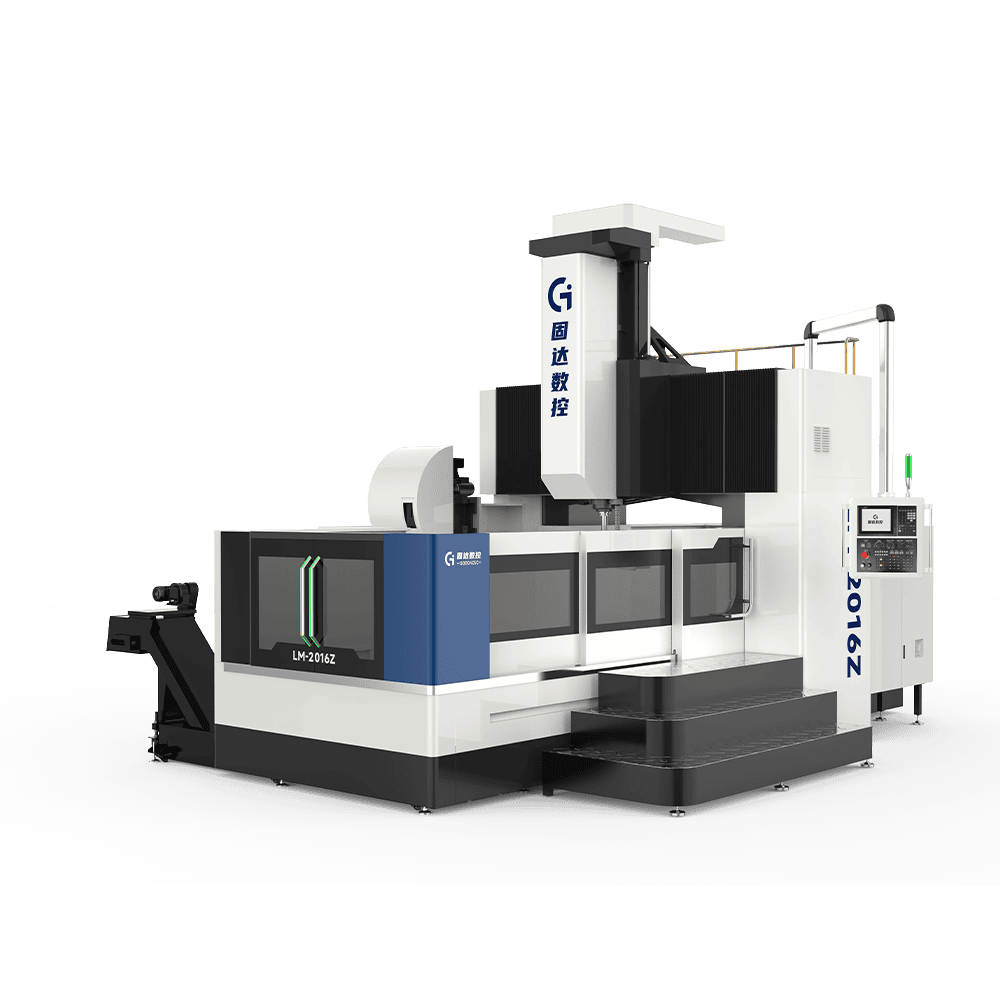

CNC Gantry Machining Center

Process capacity:245*500mm One-timedata setting, automatic positioning & measurement,automatic processing.

CNC Gantry Machining Center

Process capacity:390*800mm One-timedata setting, automatic positioning & measurement,automatic processing.

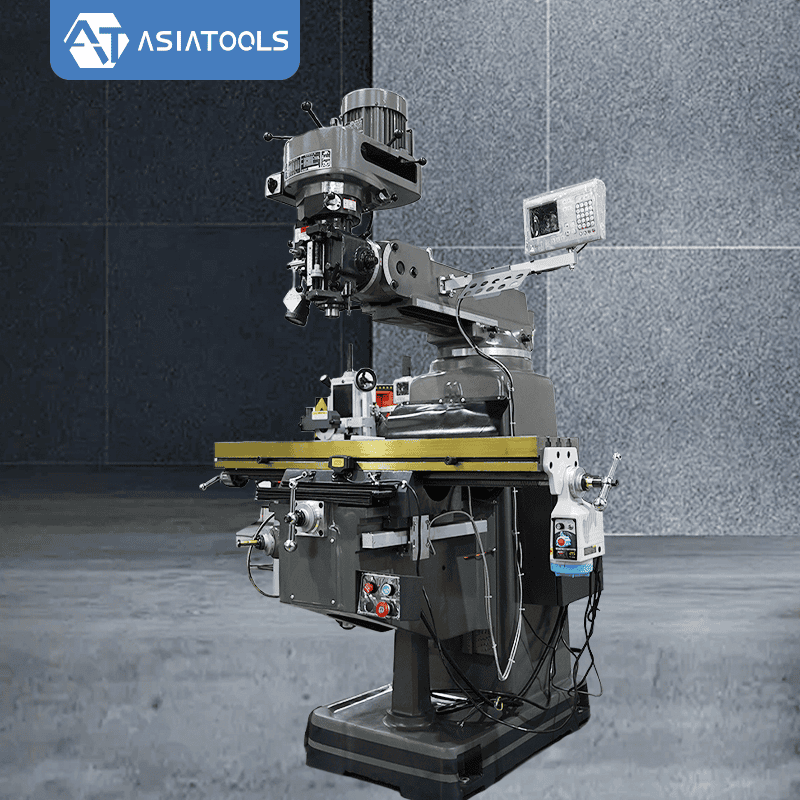

Turret Milling Machine

Spindle speed: 80-5440 rpm Its universally tilting head can tilt from 90° to the left and right, and 45° forward and backward, providing flexible positioning.

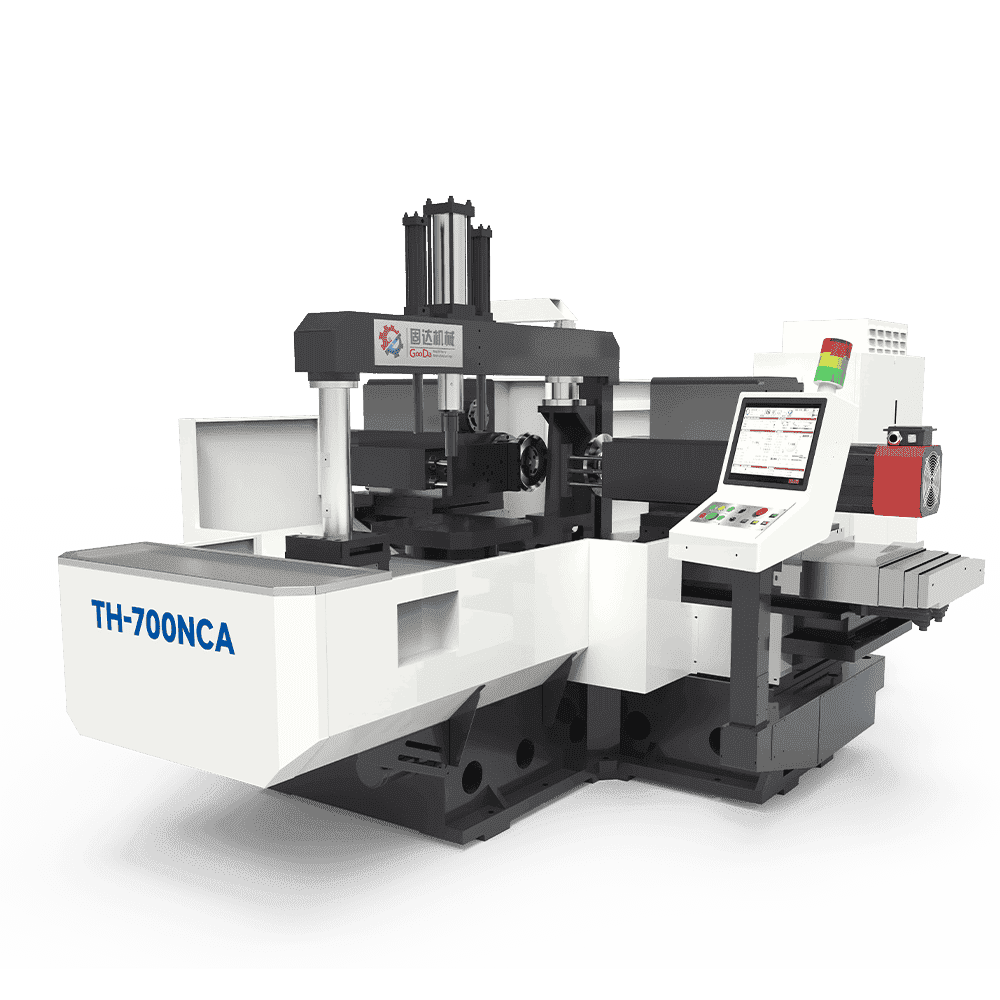

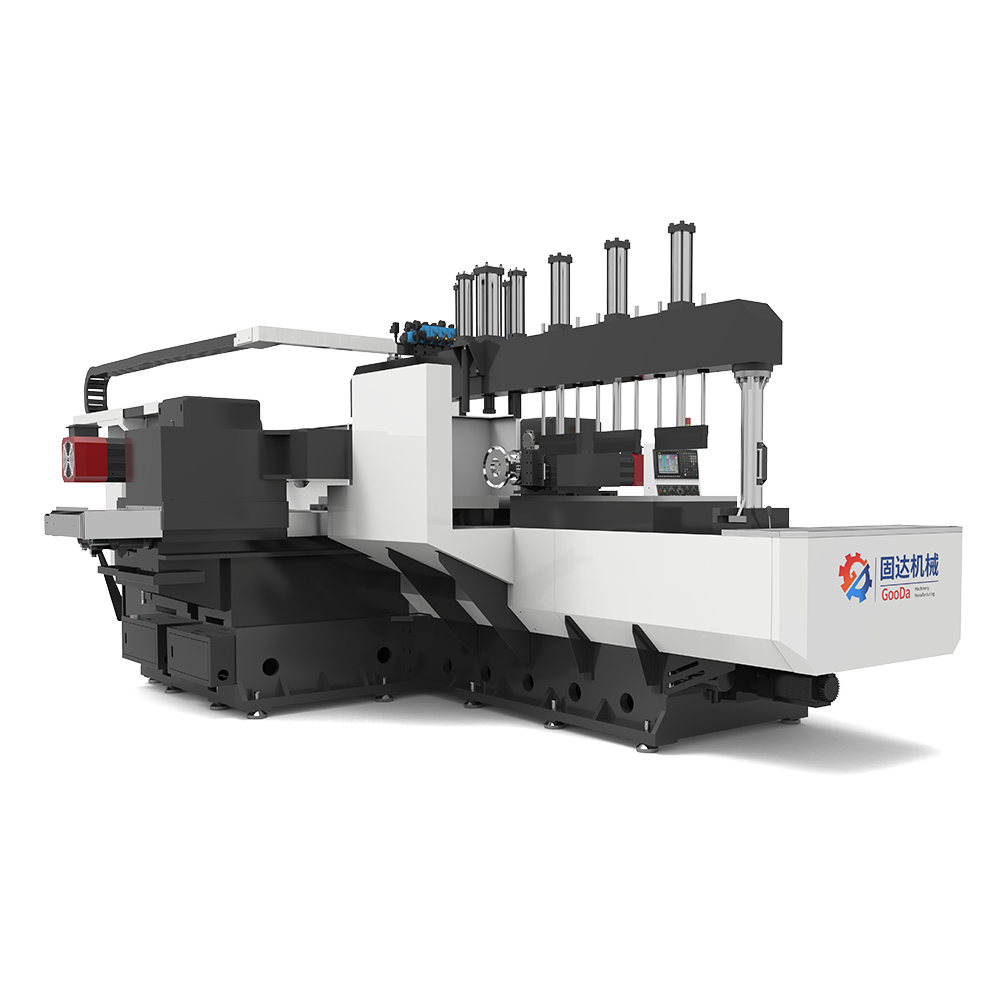

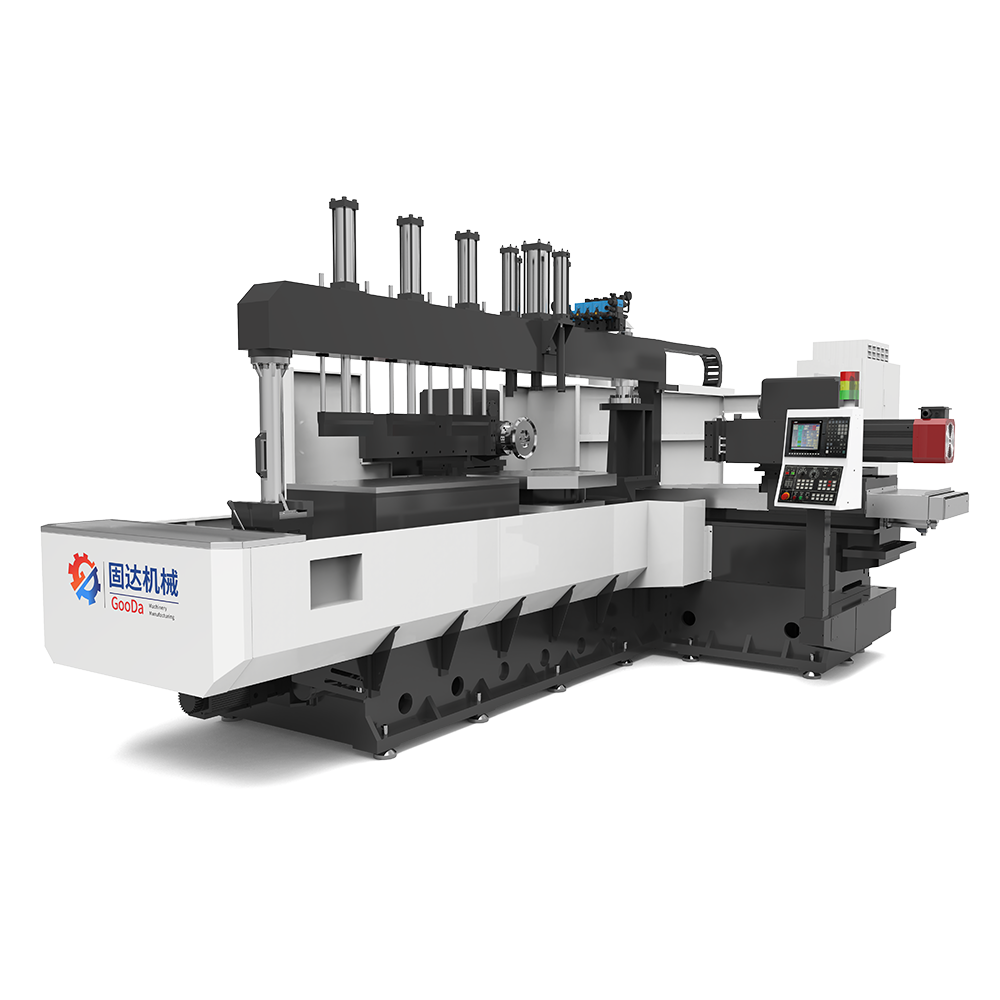

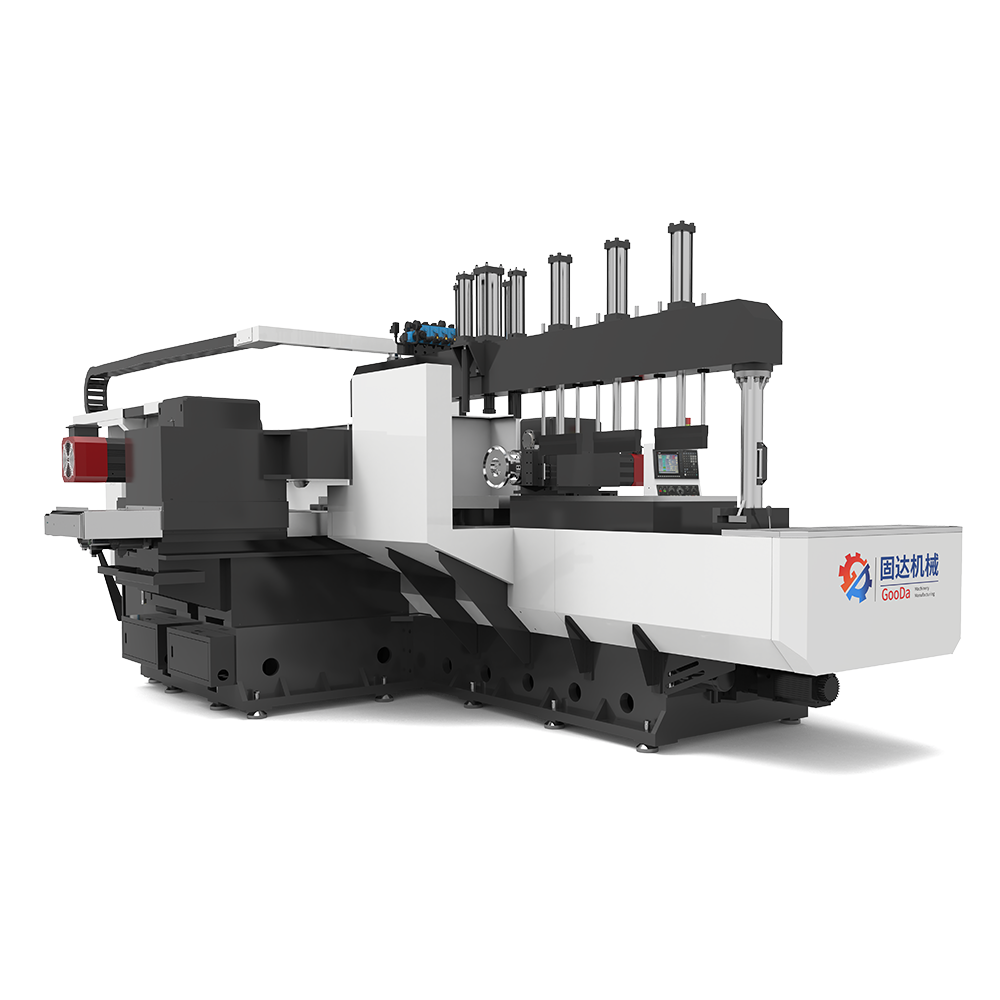

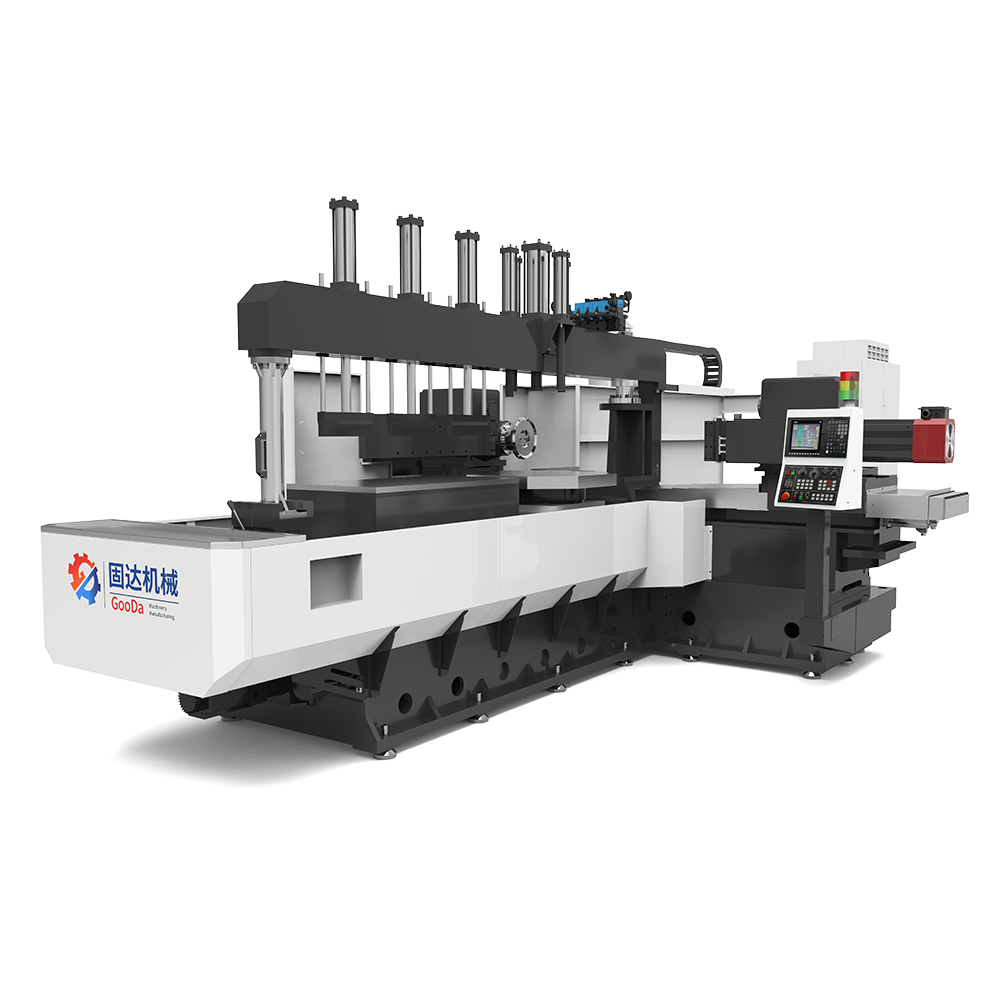

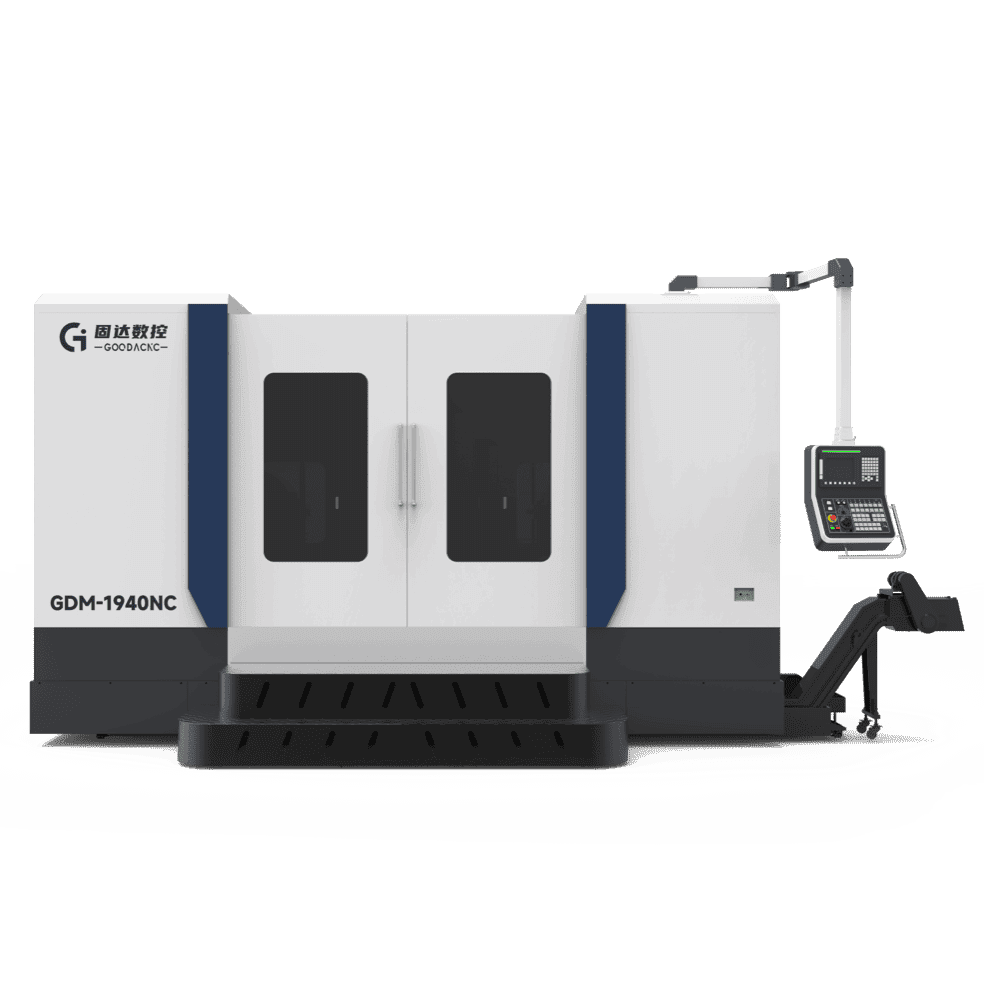

CNC Duplex Milling Machine

Process capacity:20-350mm. Complete four sides machining from rough milling to finished milling.

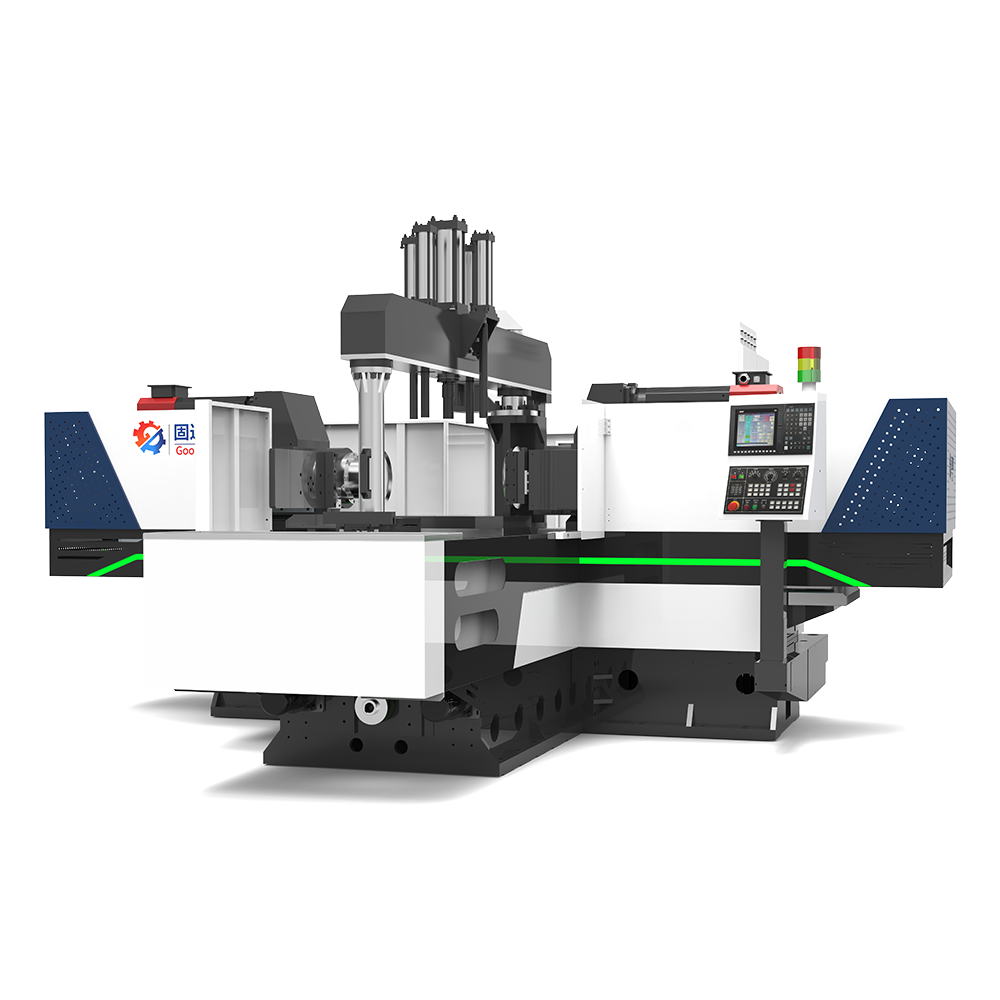

CNC Duplex Milling Machine

Process capacity:20-430mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:20-450mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:30-600mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:30-700mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:60-850mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:800-1000mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:150-1300mm. Complete four sides machining from rough milling to finished milling.

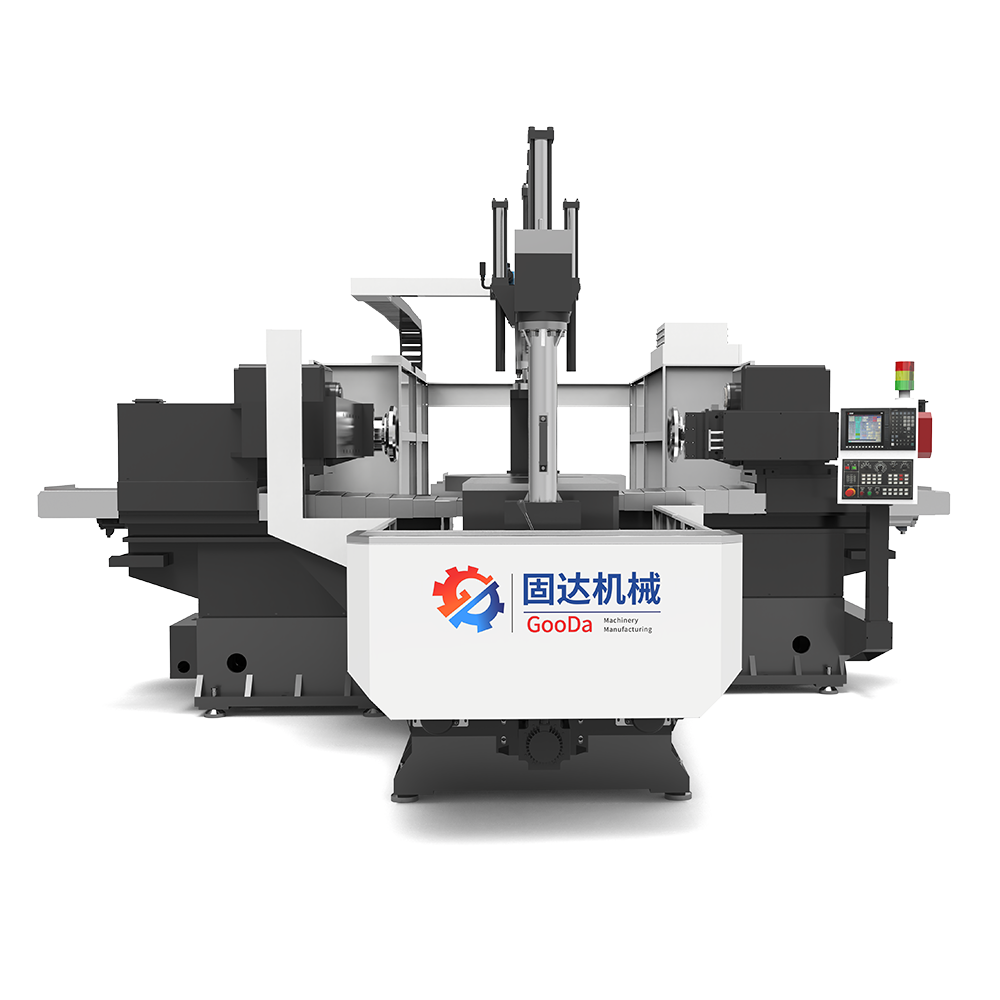

CNC Duplex Milling Machine

Process capacity:200-1500mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:200-1600mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:100-1300mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:700-1300mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:700-1500mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:850-1500mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:1300-2500mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Feed rate X/Y/Z:5000/2000/500mm/min Single-column lifting precision milling machine, with a large processing range of end milling machines.

CNC Duplex Milling Machine

Feed rate X/Y/Z:5000/2000/500mm/min Single-column lifting precision milling machine, with a large processing range of end milling machines.

Vertical Machining Center

Feed speed (X*Y*Z-axis travel):800*500*500mm. Can provide single-setup complete part machining such as milling, drilling, boring, tapping, and thread milling.

Vertcal Machining Center

Feed speed (X*Y*Z-axis travel):1100*650*600mm. Can provide single-setup complete part machining such as milling, drilling, boring, tapping, and thread milling.

Vertcal Machining Center

Feed speed (X*Y*Z-axis travel):1200*700*700mm. Can provide single-setup complete part machining such as milling, drilling, boring, tapping, and thread milling.

Vertcal Machining Center

Feed speed (X*Y*Z-axis travel):1300*700*700mm. Suitable for machining parts such as medium and small-sized hardware, box, plate, disk, and shell-type components.

Double Column Machining Center

Travels X/Y/Z:1000/ 2000/800mm It comes standard with a Taiwan BT50-6000rpm spindle for both roughing and finishing operations.

Vertcal Machining Center

Travels X/Y/Z:1000/ 2000/800mm It integrates multiple processes including milling, boring, drilling, and tapping.

Vertcal Machining Center

Travels X/Y/Z:3000/2000/1000mm A single clamping of the workpiece can complete various processes such as milling, boring, drilling, and tapping.

Vertcal Machining Center

Travels X/Y/Z:3200/2760/1000mm A single clamping of the workpiece can complete various processes such as milling, boring, drilling, and tapping.

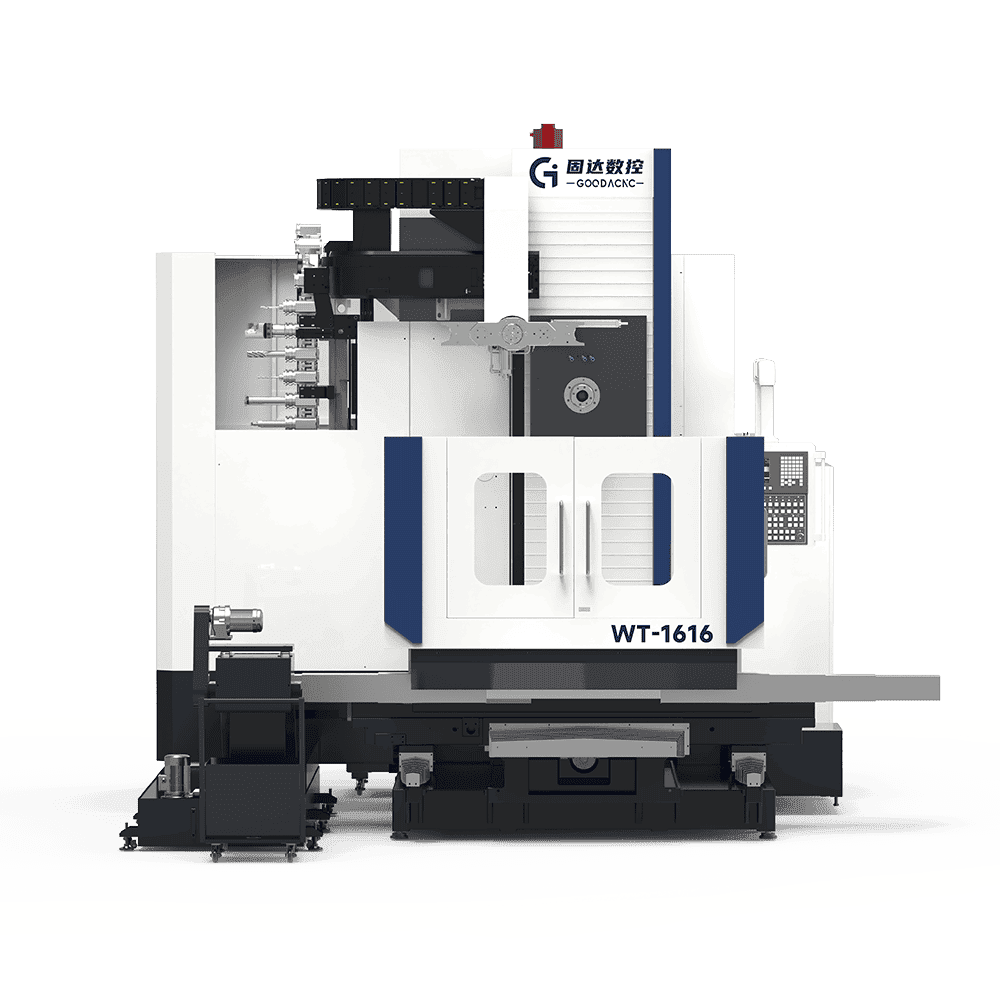

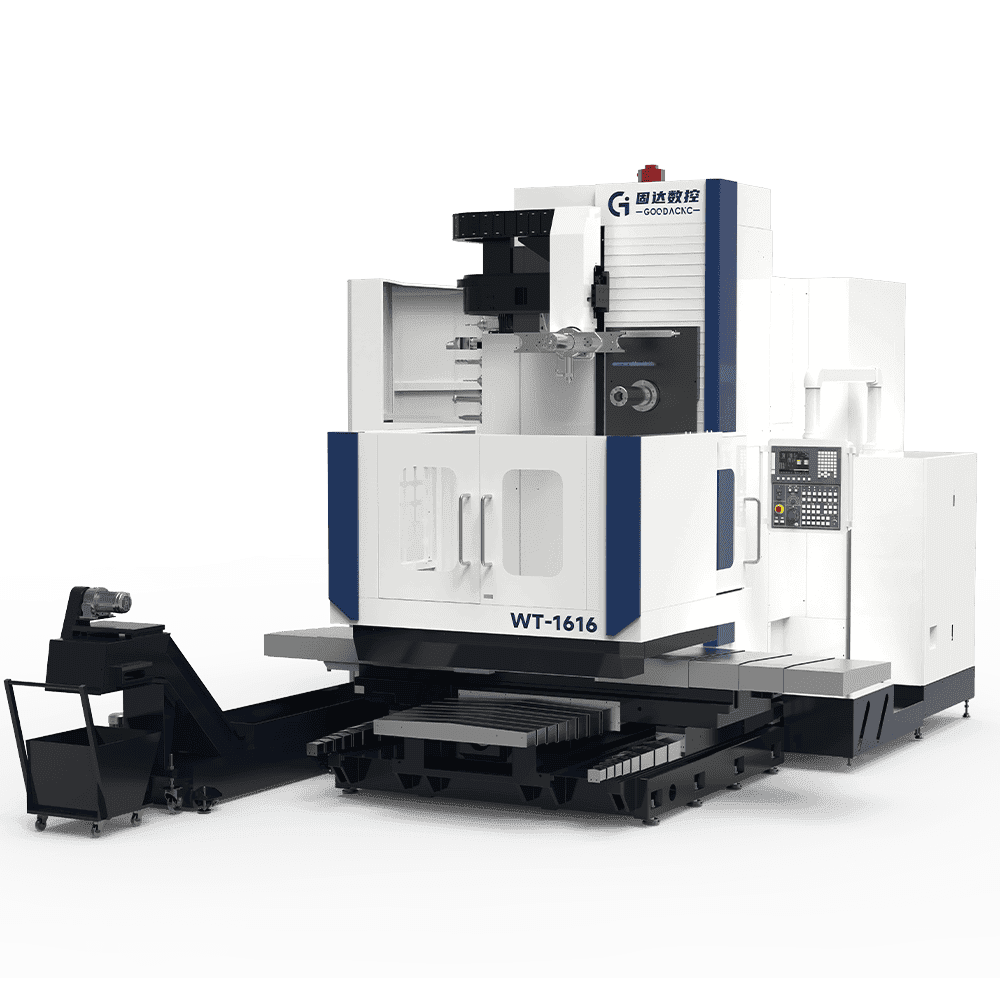

Twin Spindle Horinzontal Machining Center

Travels X/Y/Z:800/ 350/400mm It has multi-process processing technologies such as surface milling, driling and tapping, and can achieveone-time clamping & forming processing technology.

Twin Spindle Horinzontal Machining Center

Travels X/Y/Z:500/500/300mm It has multi-process processing technologies such as surface milling, driling and tapping, and can achieveone-time clamping & forming processing technology.

Twin Spindle Horinzontal Machining Center

Feed speed:8000mm/min It can achieve drilling through-holes and blind holes on single-material parts or composite materials, and can achieve large-scale production with automation and high precision.

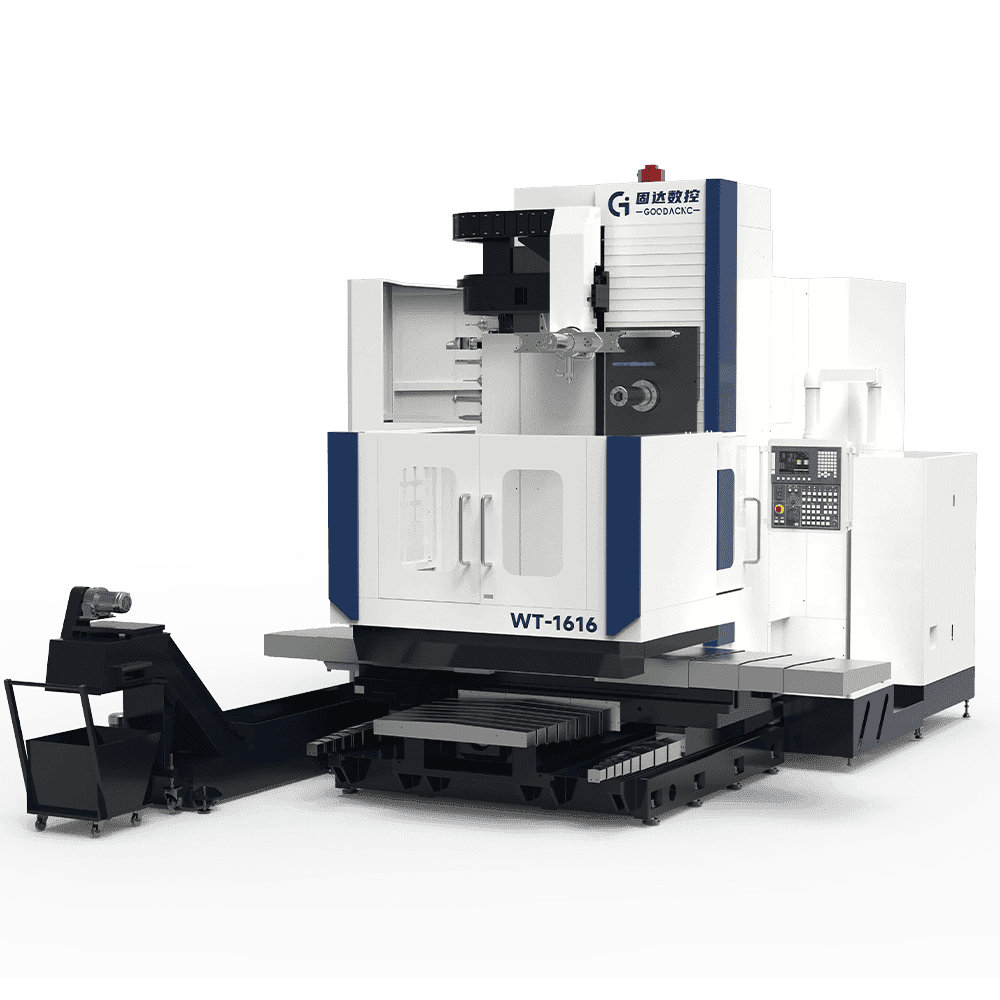

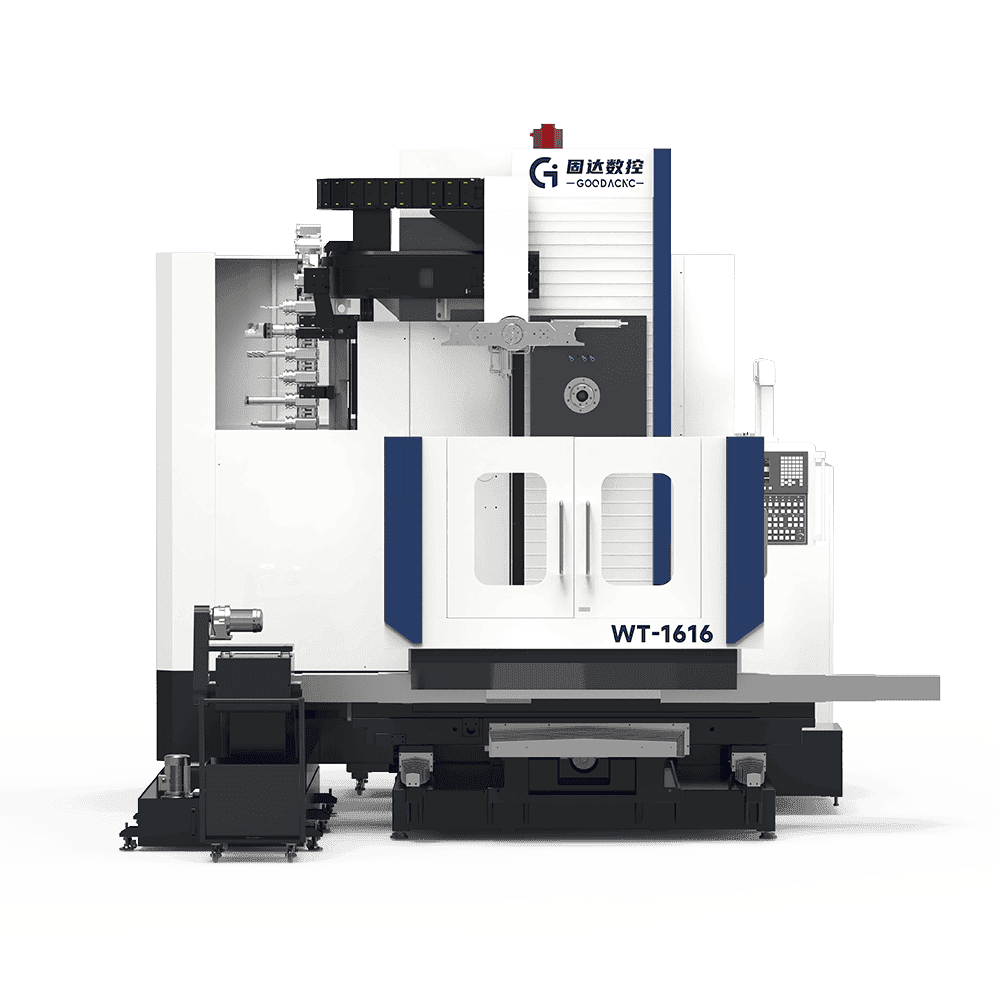

CNC Horizontal Machining Centers

Process capacity:1800*1500*850mm. It is heavy-duty cutting and heavy-load, and is a durable tool for rough and finish machining.

CNC Horizontal Machining Centers

Process capacity:2000*1500*850mm. It is heavy-duty cutting and heavy-load, and is a durable tool for rough and finish machining.

CNC Horizontal Machining Centers

Process capacity:2500*1500*850mm. It is heavy-duty cutting and heavy-load, and is a durable tool for rough and finish machining.

CNC Horizontal Machining Centers

Process capacity:3000*1500*850mm. The machine tool adopts floor-type structure with an X-axis moving column, surrounded by guideways on three sides.

CNC Horizontal Machining Centers

Process capacity:3000*2000*850mm. The machine tool adopts floor-type structure with an X-axis moving column, surrounded by guideways on three sides.

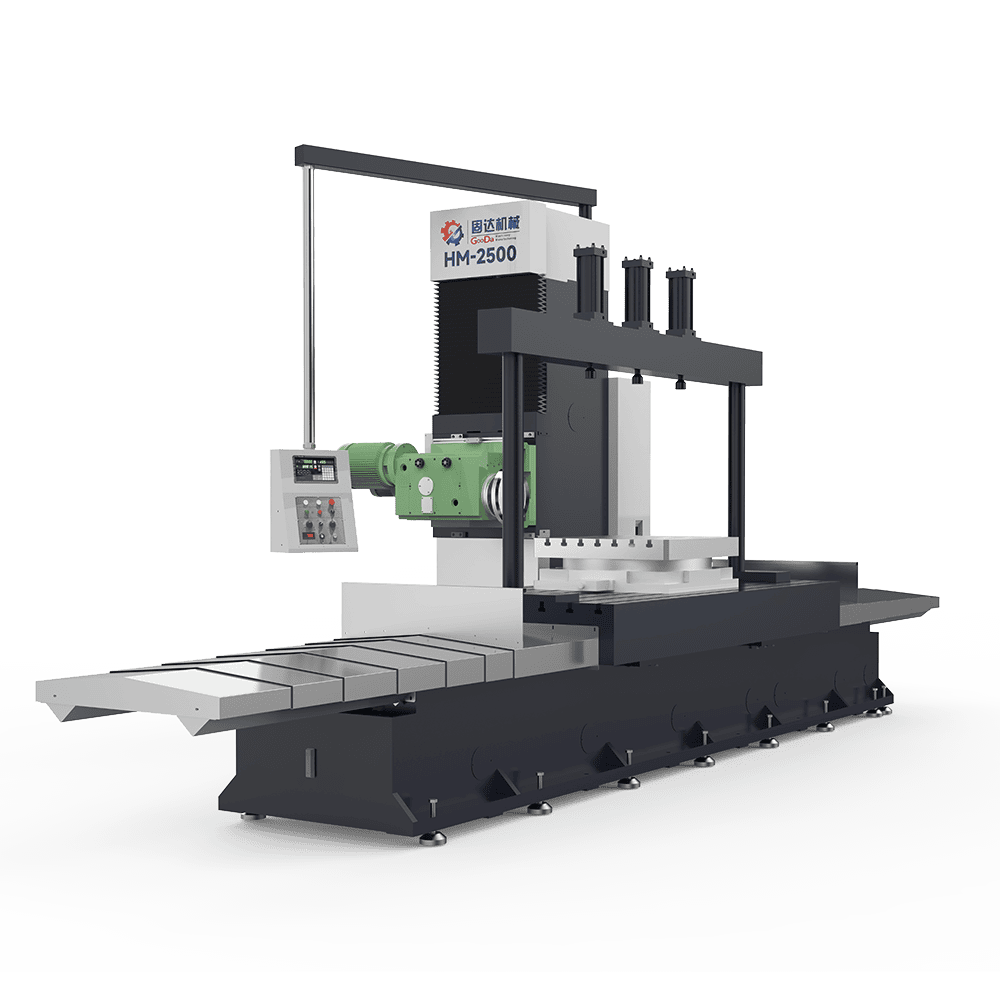

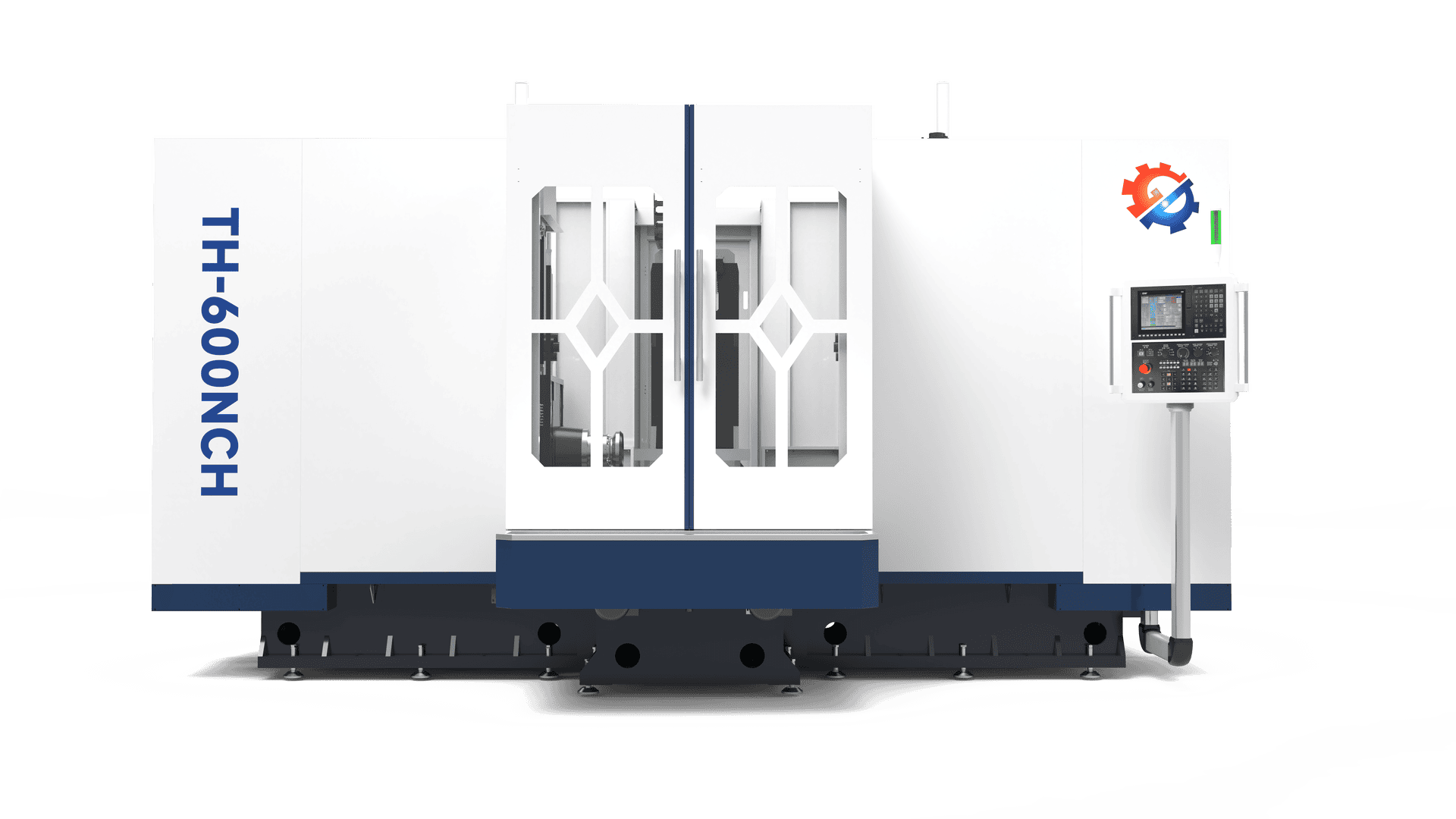

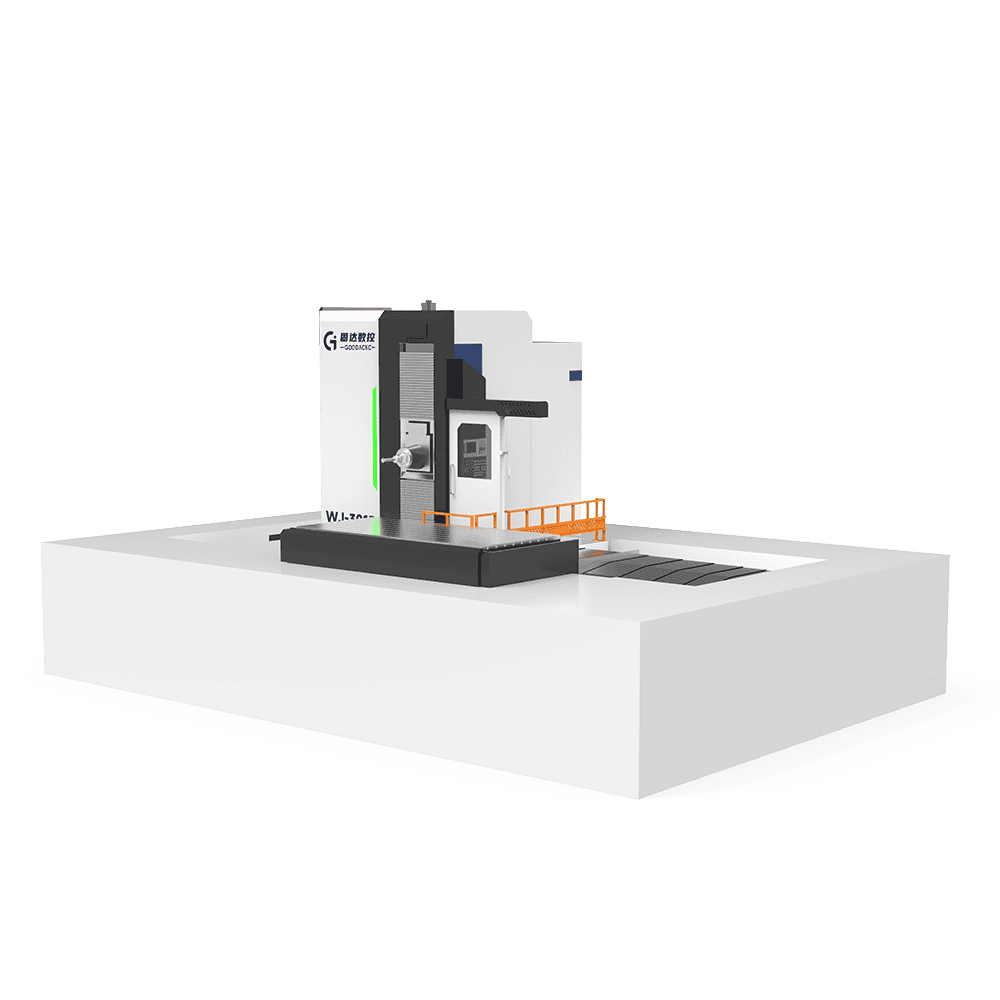

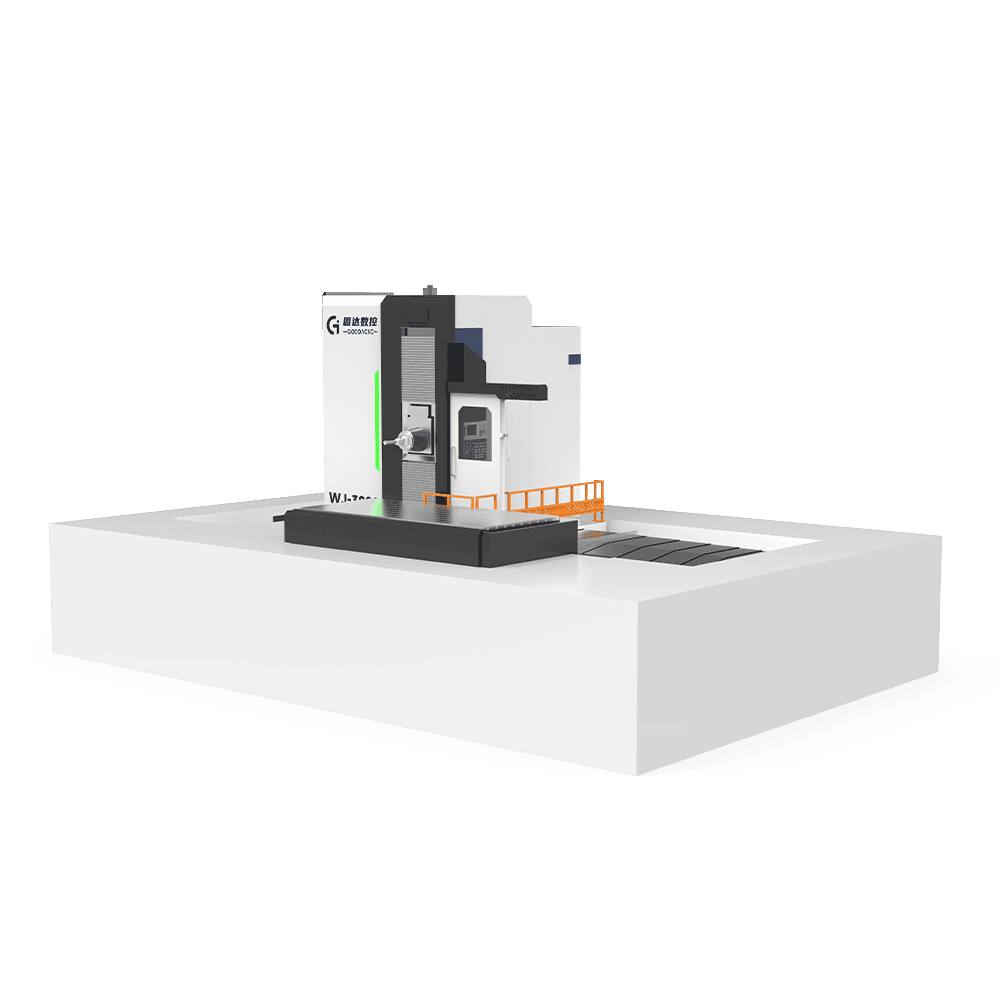

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

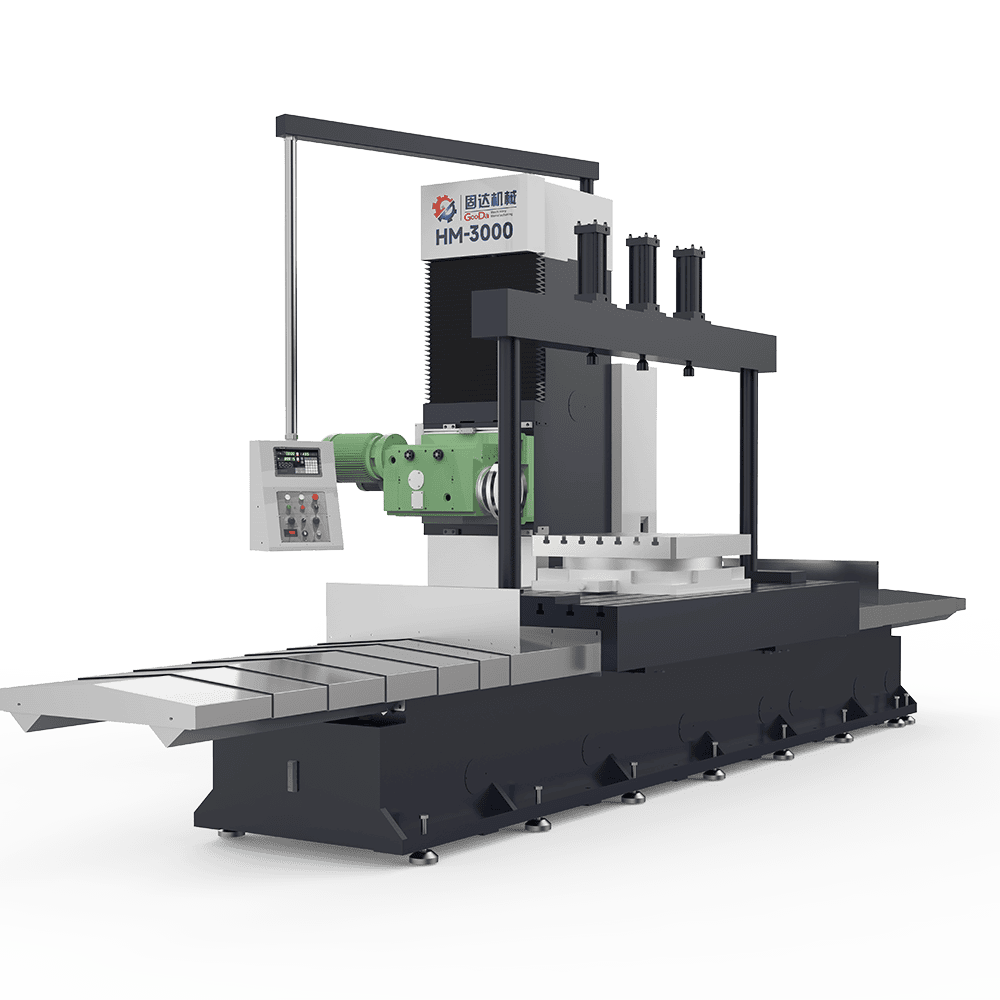

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

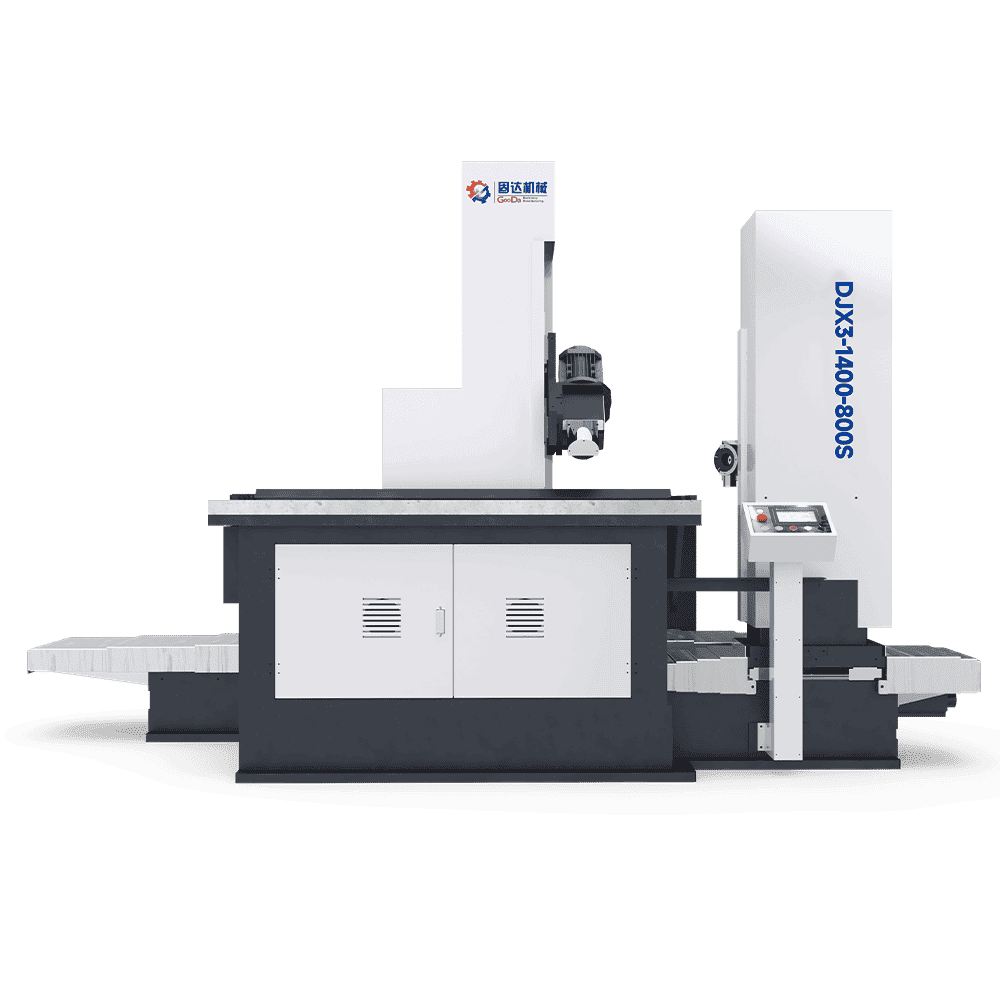

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):1500*900*450mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):2000*1000*450mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):2000*1600*600mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):3000*1600*600mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):2500*1600*600mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):6000*2800*1200mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):6000*3200*1200mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

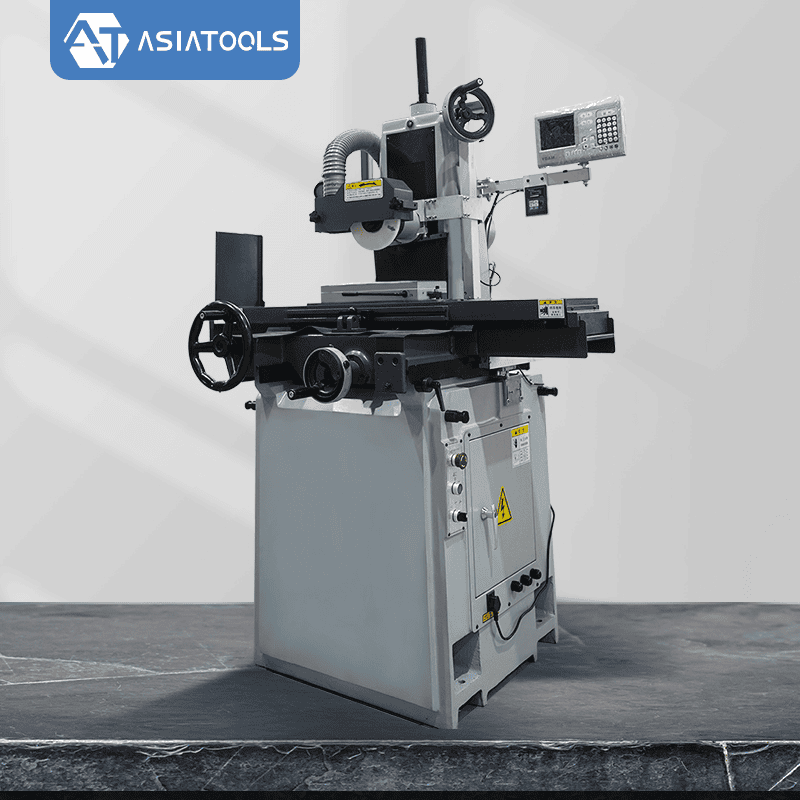

AGM-450G

Max. Table Travel: 475mm The table uses hardened steel linear rails with precision ball bearings for smooth, effortless hand-feeding

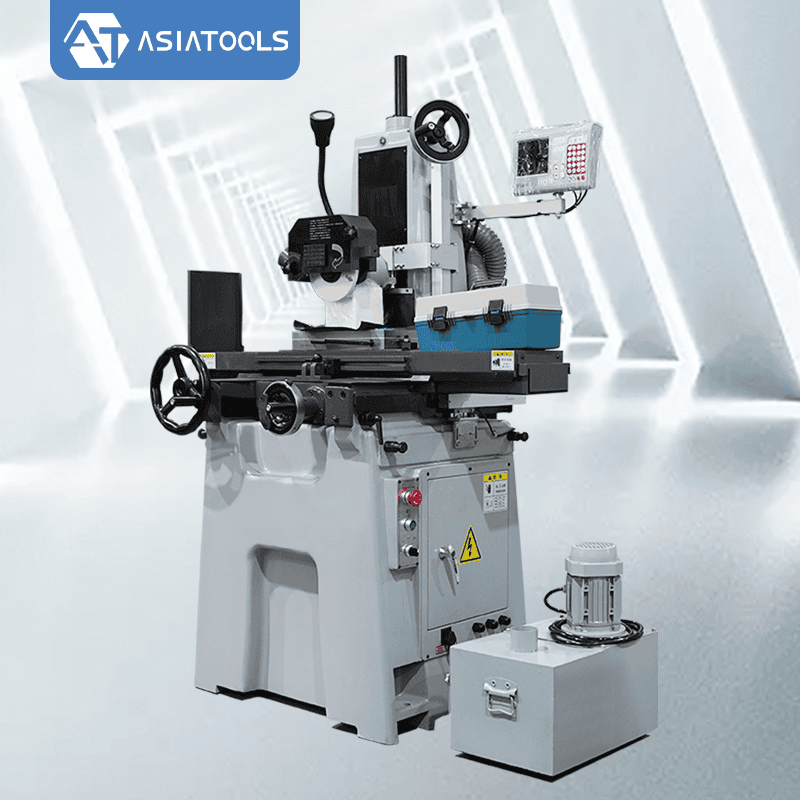

AGM-618S

Max. Table Travel: 475mm The table uses hardened steel linear rails with precision ball bearings for smooth, effortless hand-feeding

CNC Chamfering Machine

Process capacity:(20-300)*(150-600)*(150-1000)mm It's suitable for metal cutting industriesinvolving mold steel, aluminum, and mold processing.

CNC Surface Grinding Machine

Process capacity:(20-300)*(150-700)*(150-1200)mm It's suitable for metal cutting industriesinvolving mold steel, aluminum, and mold processing.

CNC Surface Grinding Machine

Process capacity:(20-300)*(150-800)*(150-1400)mm It's suitable for metal cutting industriesinvolving mold steel, aluminum, and mold processing.

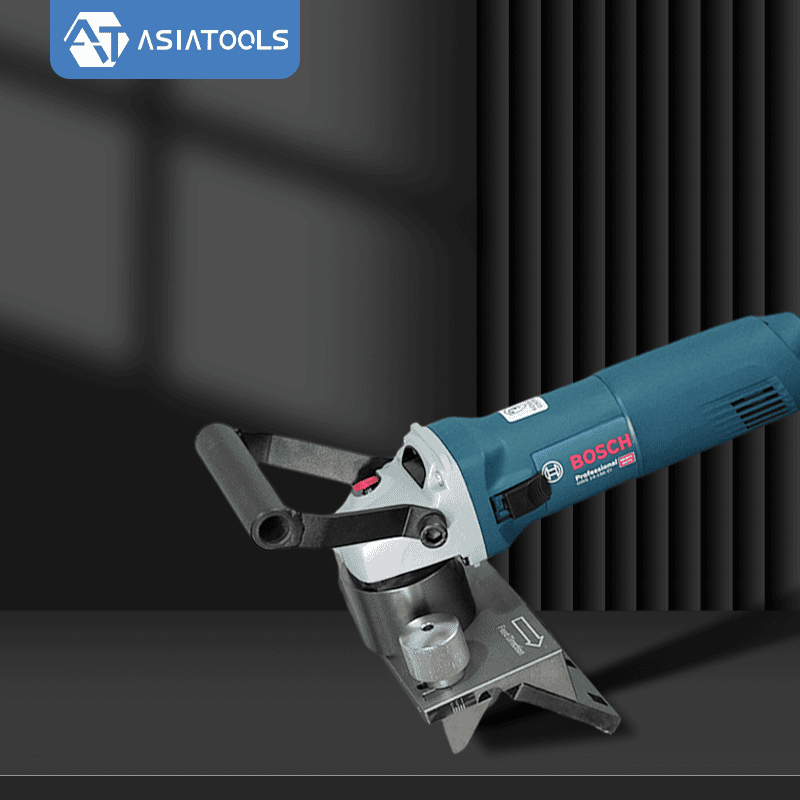

Compound Chamfering Machine

Rated Power: 750W This machine can chamfer and deburr various materials, such as iron, aluminum, copper, etc.

Compound Chamfering Machine

Rated Power: 750W This machine can chamfer and deburr various materials, such as iron, aluminum, copper, etc.

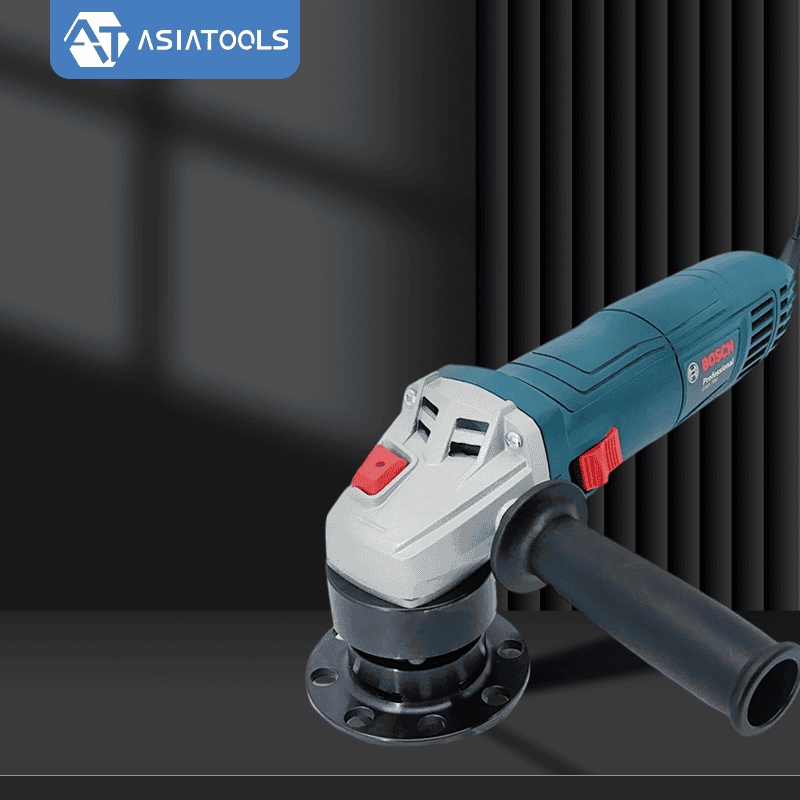

Portable Chamfering Machine

Blade model: AGF-390A Curved edges and round holes chamfering.

Portable Chamfering Machine

Blade model: AGF-390A Straight edge chamfering without guide wheel wear.

Portable Chamfering Machine

Rated Power: 750W This machine can chamfer and deburr various materials, such as iron, aluminum, copper, etc.

Portable Chamfering Machine

Rotating Speed: 12000rmp This handheld chamfering machine features a dual-purpose blade switch, allowing it to process both 45° angles and R angle.

Portable Chamfering Machine

Rotating Speed: 12000rmp The portable machine can process 45° angle with options for chamfering depths of 0–2mm.

Portable Chamfering Machine

Rotating Speed: 12000rmp The portable machine can process 45° angle with options for chamfering depths of 0–2mm.

CNC Circular Saw Cutting Machine

Cutting range square (W*H): 700*100mmmm. Suitable for high-strengthstructural steel, tool steel, alloy steel,For the sawing of wear-resistant steel and other metal sheets.

CNC Circular Saw Cutting Machine

Cutting range square (W*H): 1000*100mmmm. Suitable for high-strengthstructural steel, tool steel, alloy steel,For the sawing of wear-resistant steel and other metal sheets.

CNC Circular Saw Cutting Machine

Cutting range square (W*H): 1600*100mmmm. Suitable for high-strengthstructural steel, tool steel, alloy steel,For the sawing of wear-resistant steel and other metal sheets.

CNC Circular Saw Cutting Machine

Cutting range square (W*H): 2600*100mmmm. Suitable for high-strengthstructural steel, tool steel, alloy steel,For the sawing of wear-resistant steel and other metal sheets.

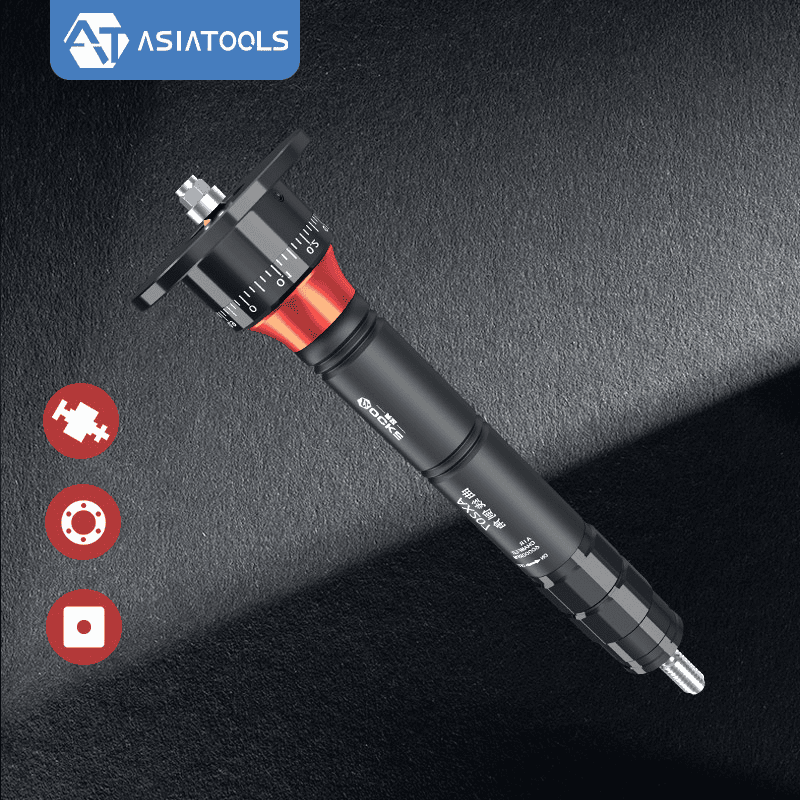

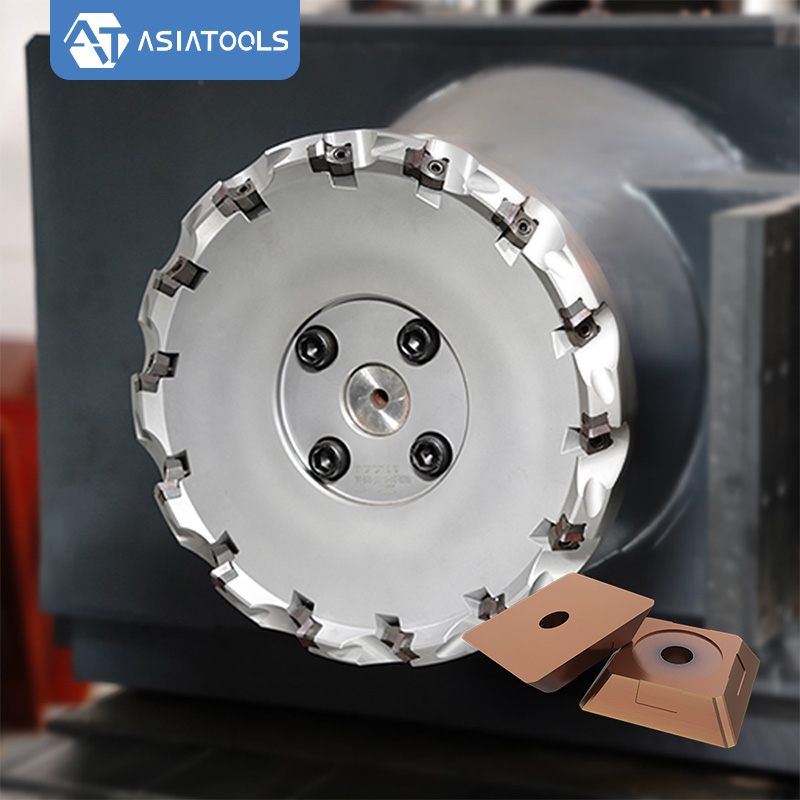

CNC Cutting Tools

Precision-engineered for high performance, our CNC cutting tools ensure clean, accurate cuts for all your machining needs.

Saftey Shoes

Designed for durability and comfort, our safety shoes provide essential protection in demanding work environments.

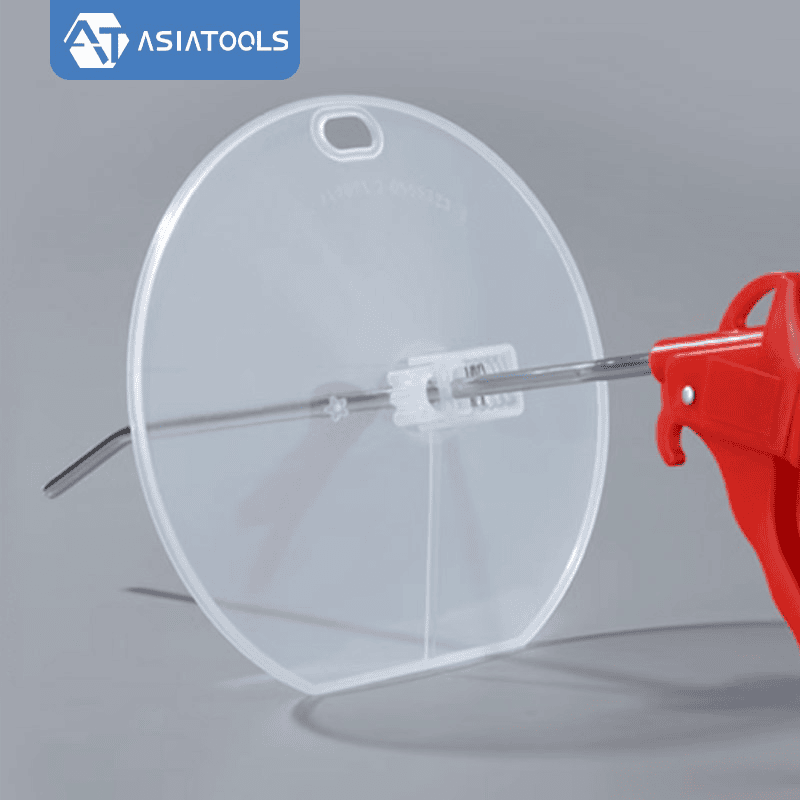

Blow Gun Chip Guarding Shield

Designed for durability and comfort, our safety shoes provide essential protection in demanding work environments.

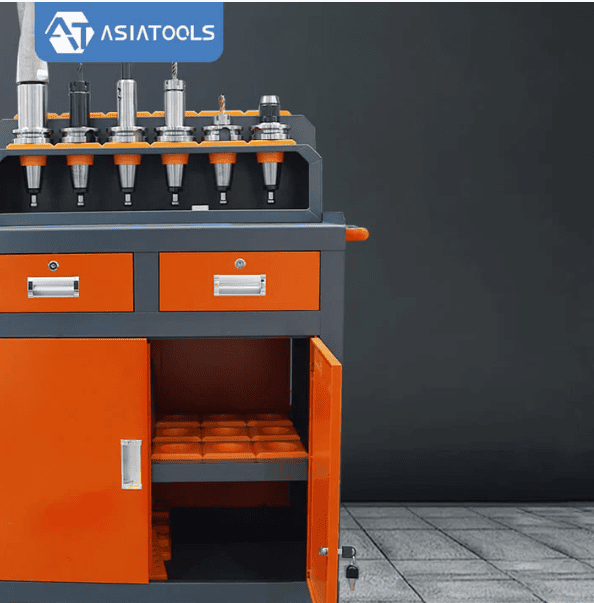

CNC Tool Holder Cart

Our CNC tool holder cart offers convenient, organized storage, and easy mobility for all your essential tools.

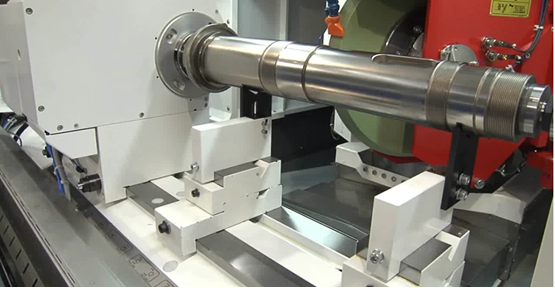

CNC Spindle Pull Claw

Ensure secure and efficient tool changes with our robust CNC spindle pull claw.

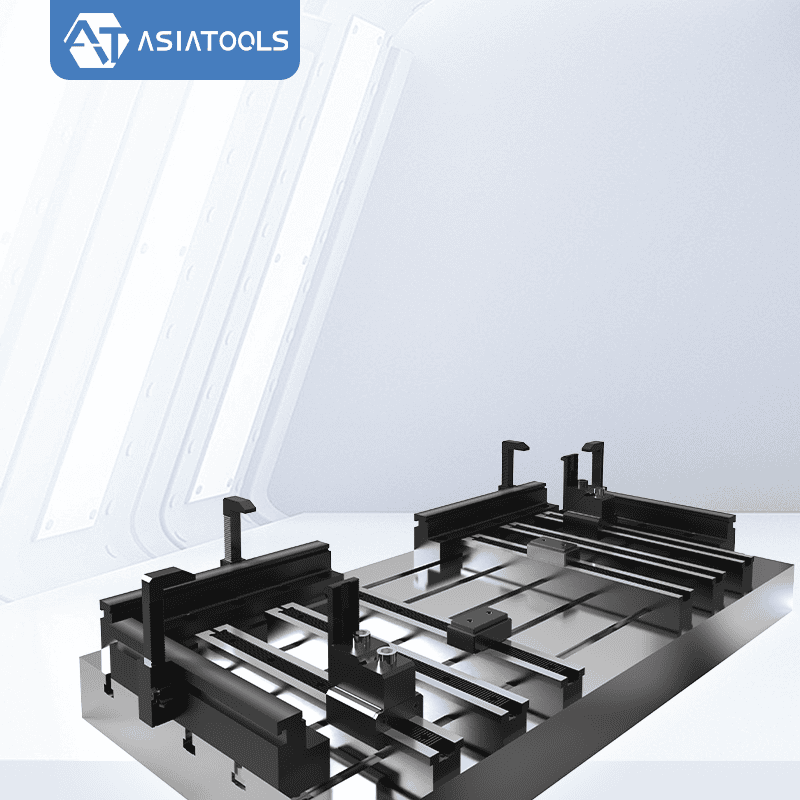

Hydraulic Clamping System

Experience superior workpiece stability and precision with our advanced hydraulic clamping system.

CNC Chip Blower

Maintain a clear and efficient workspace with our CNC chip blower, which effectively removes chips and debris.

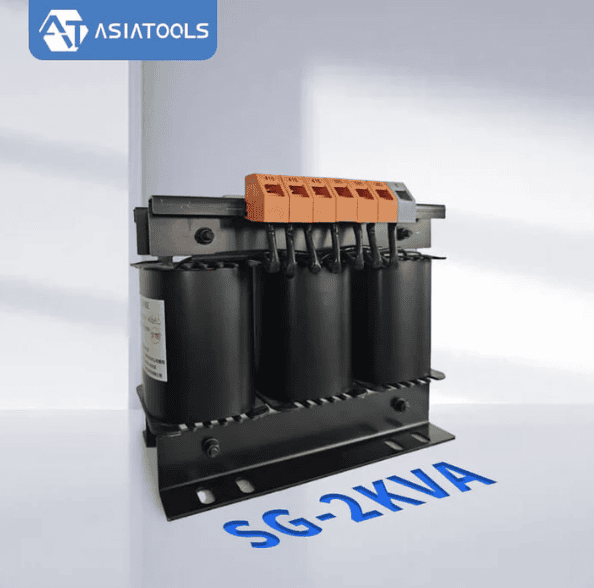

Three Phase Transformer Power Distribution

Deliver reliable and consistent power with our three-phase transformer power distribution system.

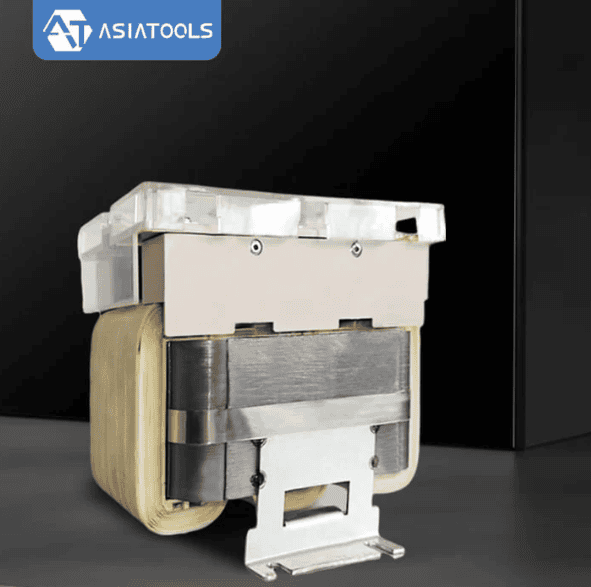

Three Phase Output Line Reactor

Protect your equipment and enhance performance with our three-phase output line reactor, designed to reduce harmonics.

Custom Mold Steel Blocks

Achieve exceptional results with our custom mold steel blocks, tailored to meet your specific design and production requirements.In modern automotive manufacturing, the use of horizontal machining center is becoming increasingly widespread. It not only improves production efficiency, but also enhances product quality and design flexibility. Today, we will delve into the specific applications of horizontal machining center in the automotive industry.

Firstly, from a design perspective, horizontal machining center provide great convenience for automotive manufacturing. Designers can use horizontal machining center for complex 3D model design and simulation analysis. For example, the body, seats, dashboard and other components of a car can be accurately modeled and simulated through horizontal machining center to ensure the rationality and feasibility of the design scheme.

Secondly, from the perspective of the manufacturing industry, horizontal machining center play a crucial role in the manufacturing process of automotive components. For example, the cylinder block, crankshaft, connecting rod and other components of the engine, as well as the gears, bearings, housing and other components of the transmission, can be finely cut and ground through horizontal machining center.

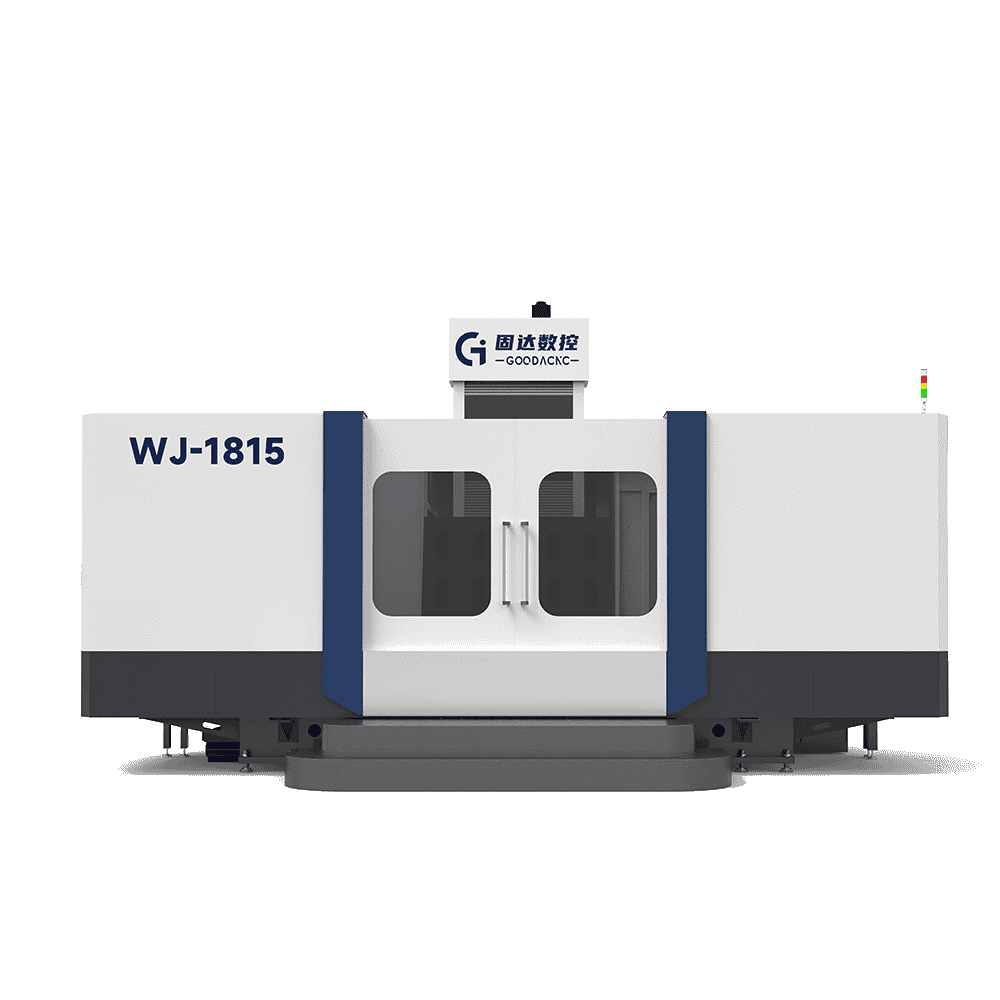

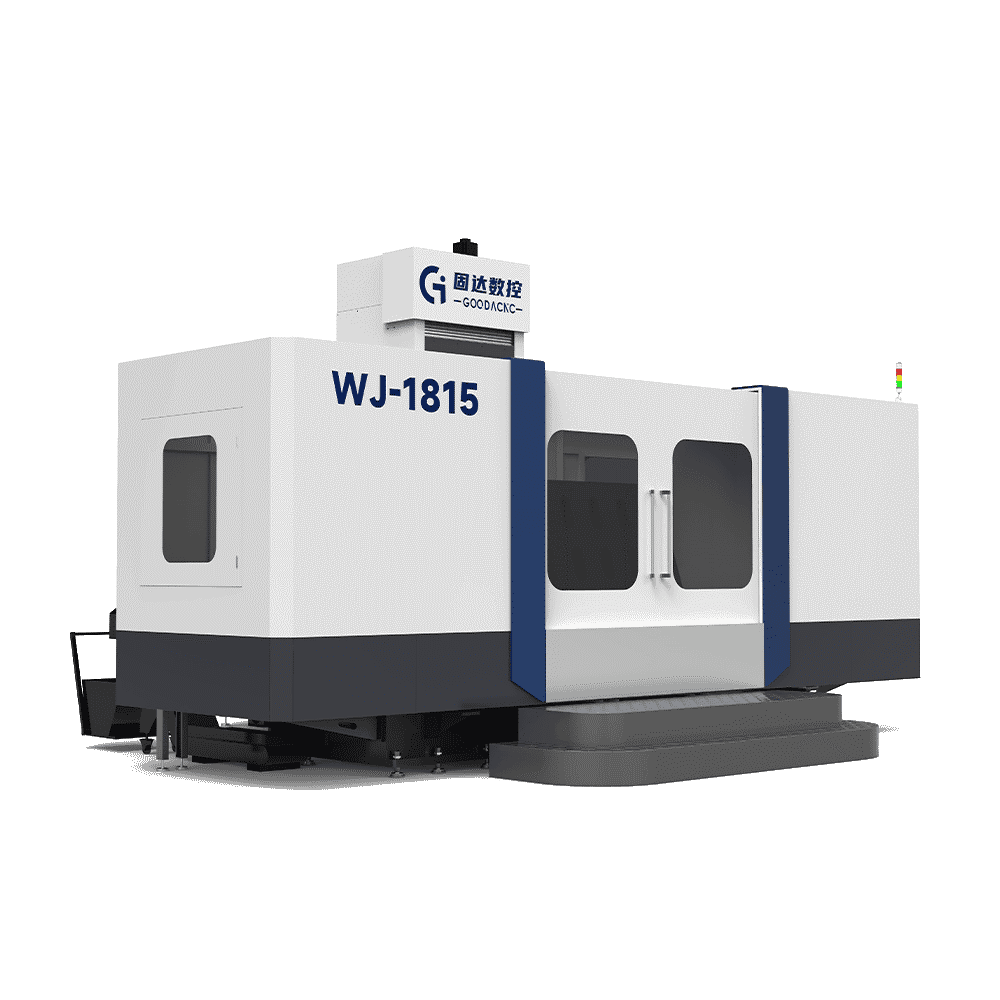

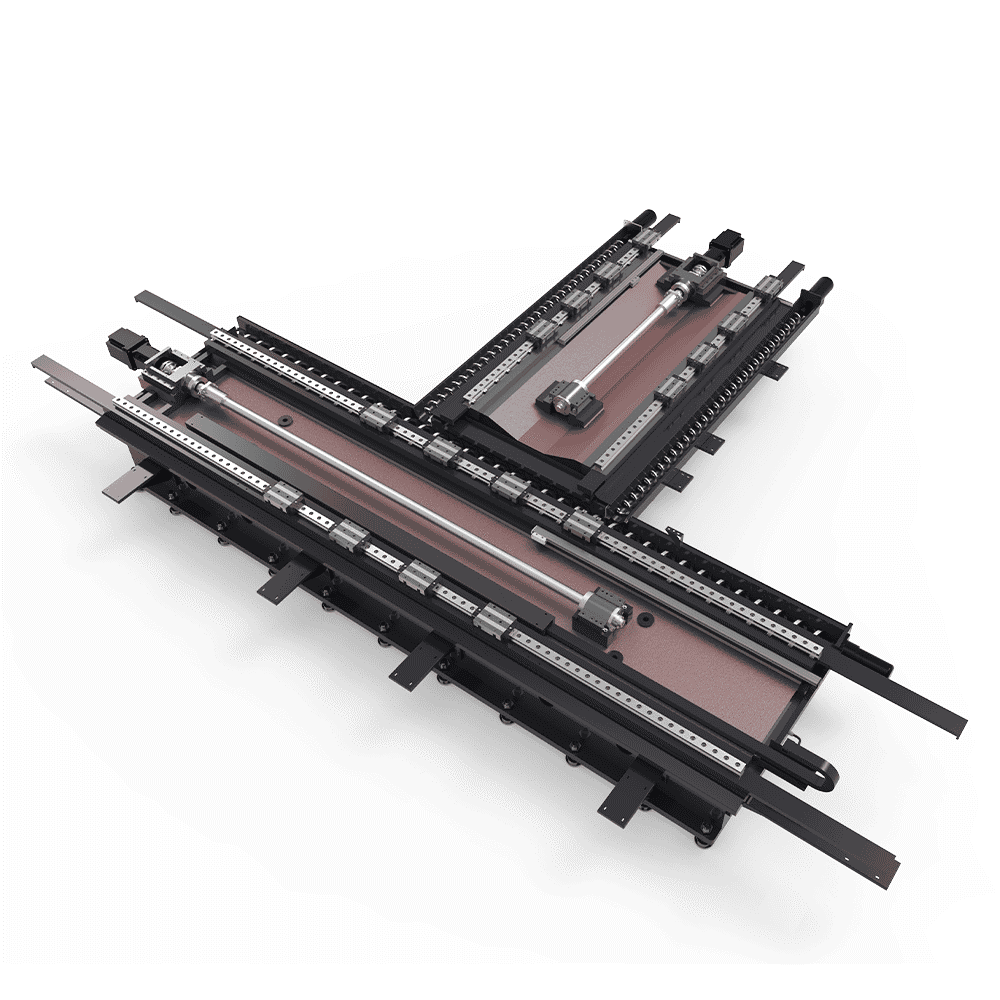

The machine tool features an overs zed invented 'T"-shaped bed base. The Y-axis uses an integrated double-wall moving column design. The spindle box is in a front-mounted configuration.

It is heavy-duty cutting and heavy-load, and is a durable tool for rough and finish machining. In order to strengthen roughing, it adopts a customized thickened spindle and is equipped with a 22kw high-torque motor.

The WJ-1815 horizontal machining center is suitable for precision molds, engineering machinery, automobile power, locomotives, ships, ocean engineering and other industries.

In addition, the equipment also adopts advanced technologies and designs such as high-speed spindles and high-precision control systems, further improving machining accuracy and efficiency.

For example, through real-time monitoring and data analysis of the processing of automotive parts, problems in the production process can be identified and solved, improving production efficiency and product quality.

The WJ-1815 horizontal machining center is widely used in the automotive industry. Its high efficiency, precision, and stability have brought great convenience to the automotive manufacturing industry.

The efficient and precise machining capability of WJ-1815 horizontal machining center not only ensures the dimensional accuracy and surface quality of parts, but also greatly improves production efficiency and reduces production costs. Again, from an optimization perspective, horizontal machining centers have also played an important role in the automotive manufacturing process.

The WJ-1815 horizontal machining center is widely used in the automotive industry. Its high efficiency, precision, and stability have brought great convenience to the automotive manufacturing industry. The WJ-1815 horizontal machining center sets a new standard for horizontal machining and provides support for users to achieve sustainable, efficient, and competitive CNC manufacturing in the future.

The WJ-1815 horizontal machining center is designed for high demand components in tool and mold manufacturing, as well as energy and green technology fields, including drive technology for electric vehicles. With its stability, precision, and versatility in processing, it has become the perfect foundation for transformation at all levels of processing. They allow for high process integration, flexible automation, and optimal preparation for digital transformation. In the future, with the further development of the automotive manufacturing industry, we look forward to horizontal machining centers playing a greater role in promoting the progress of the automotive industry.