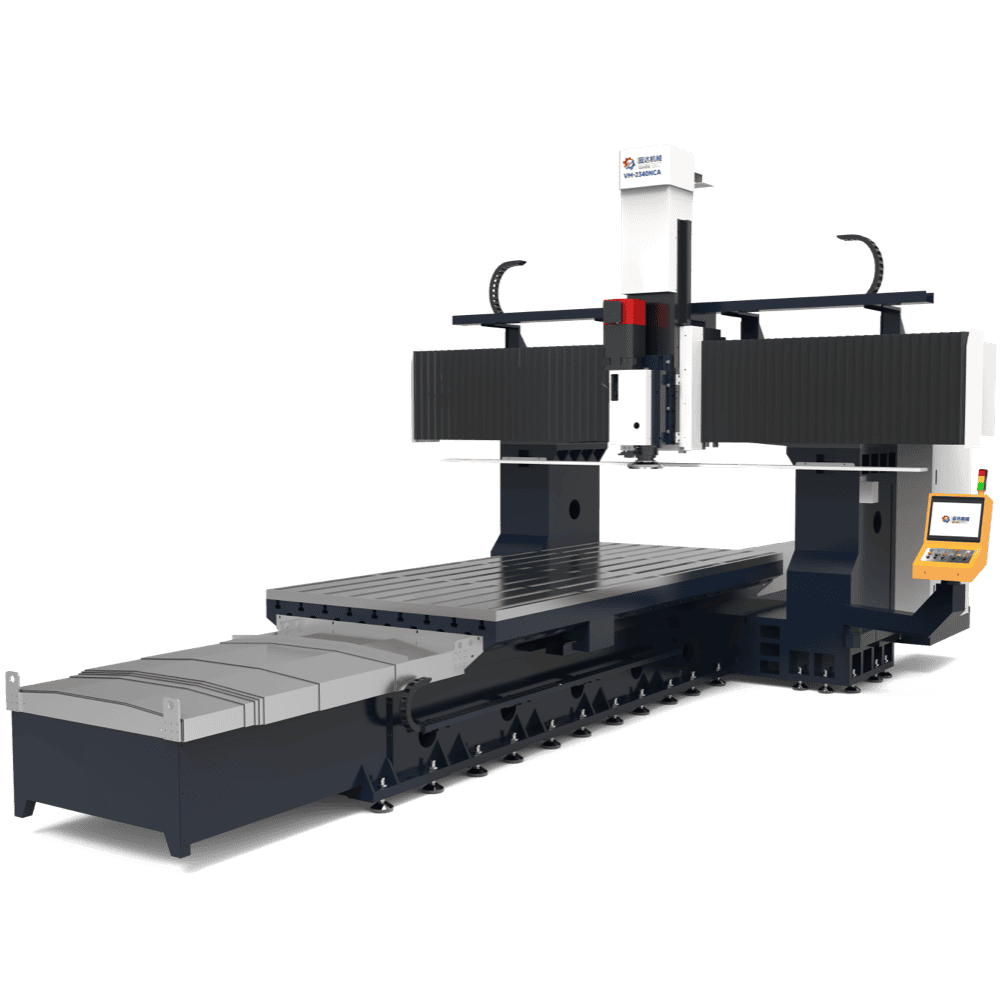

VM-2340

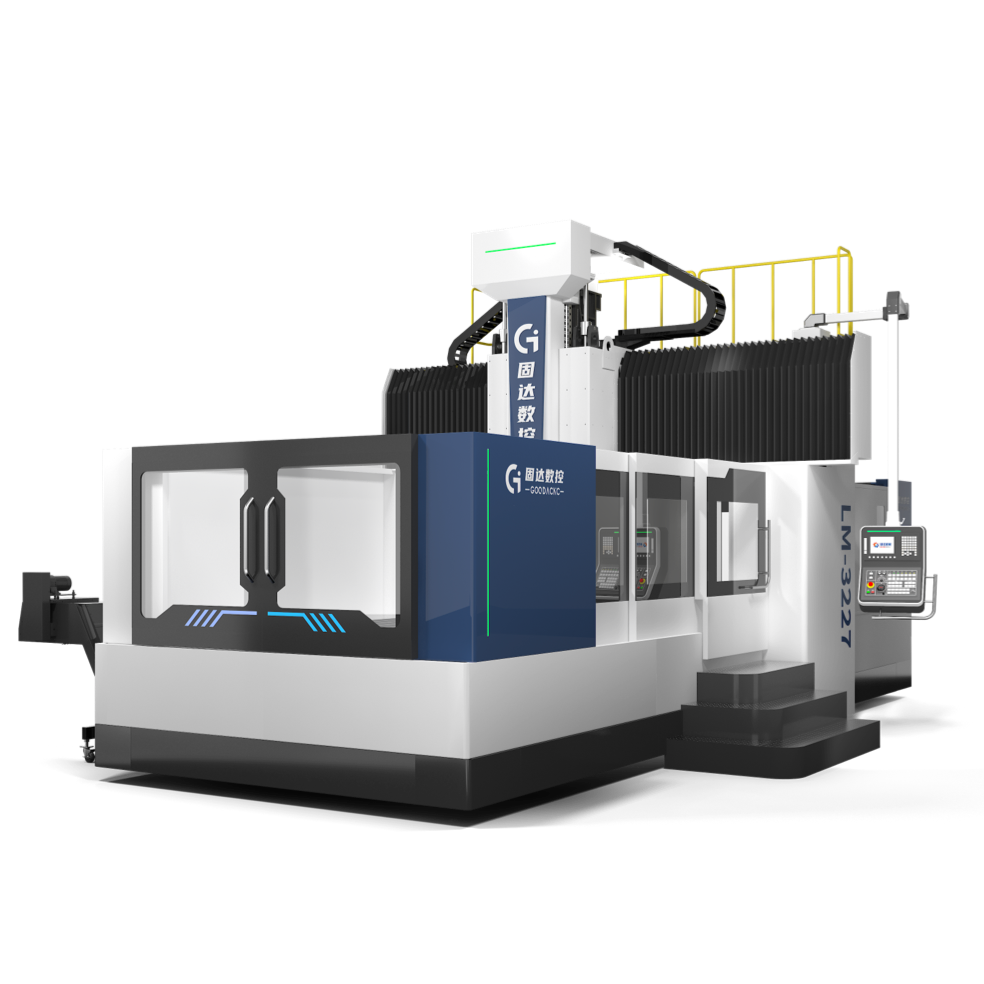

CNC Gantry Milling Machine

Process capacity:1800*4000mm. Gear box type spindles with high torque spindle motors.

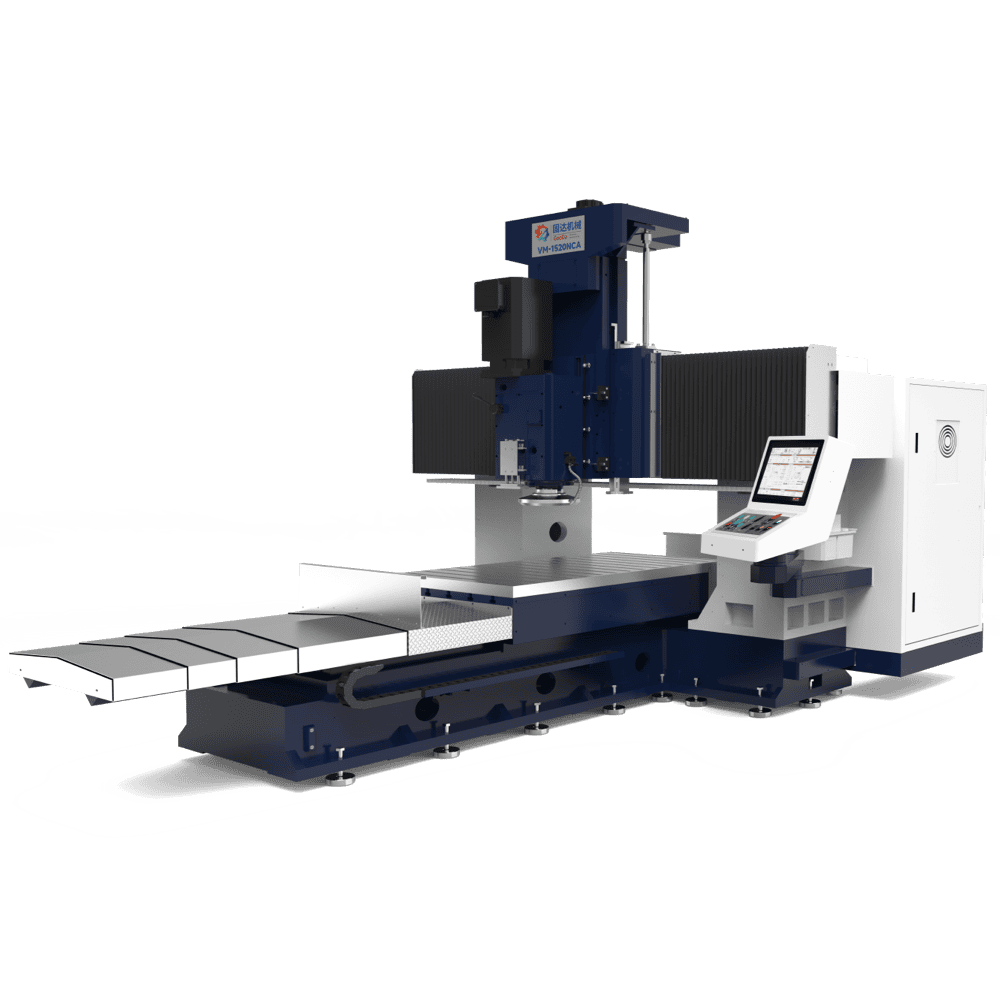

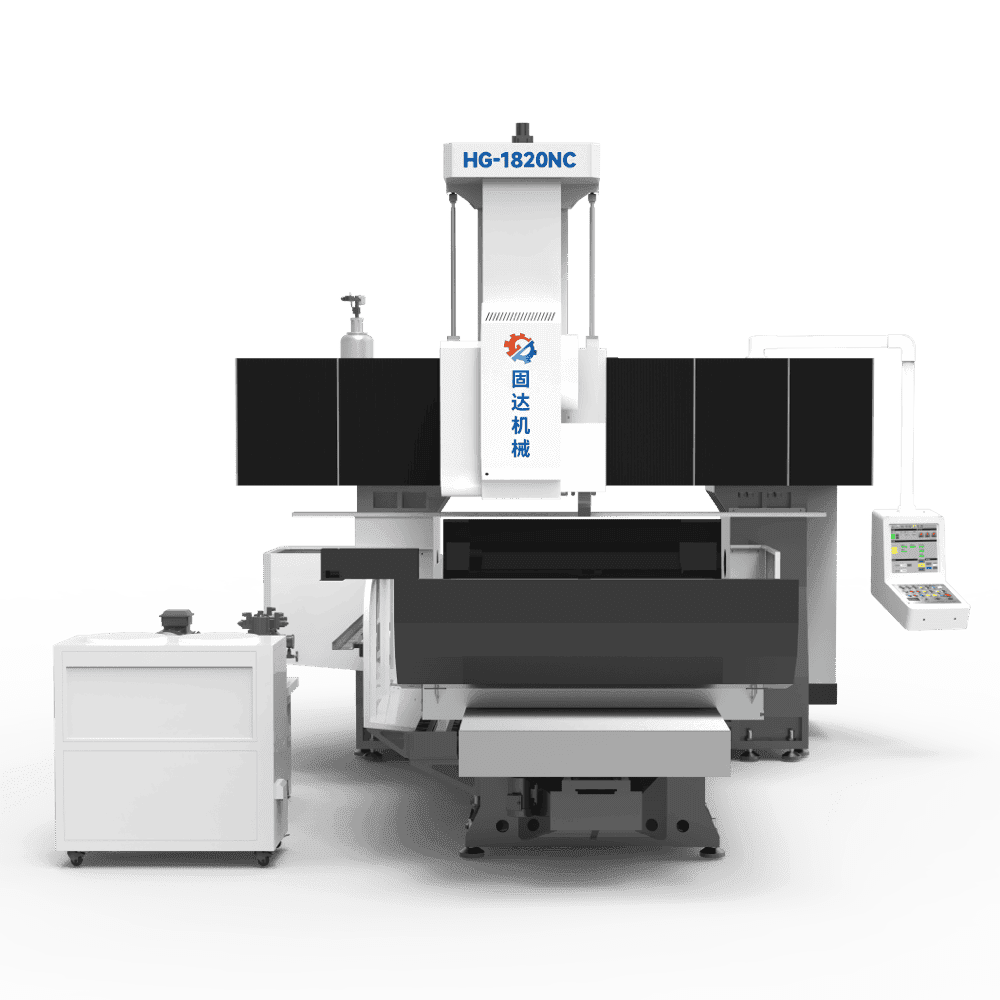

CNC Gantry Milling Machine

Process capacity:1800*4000mm. Gear box type spindles with high torque spindle motors.

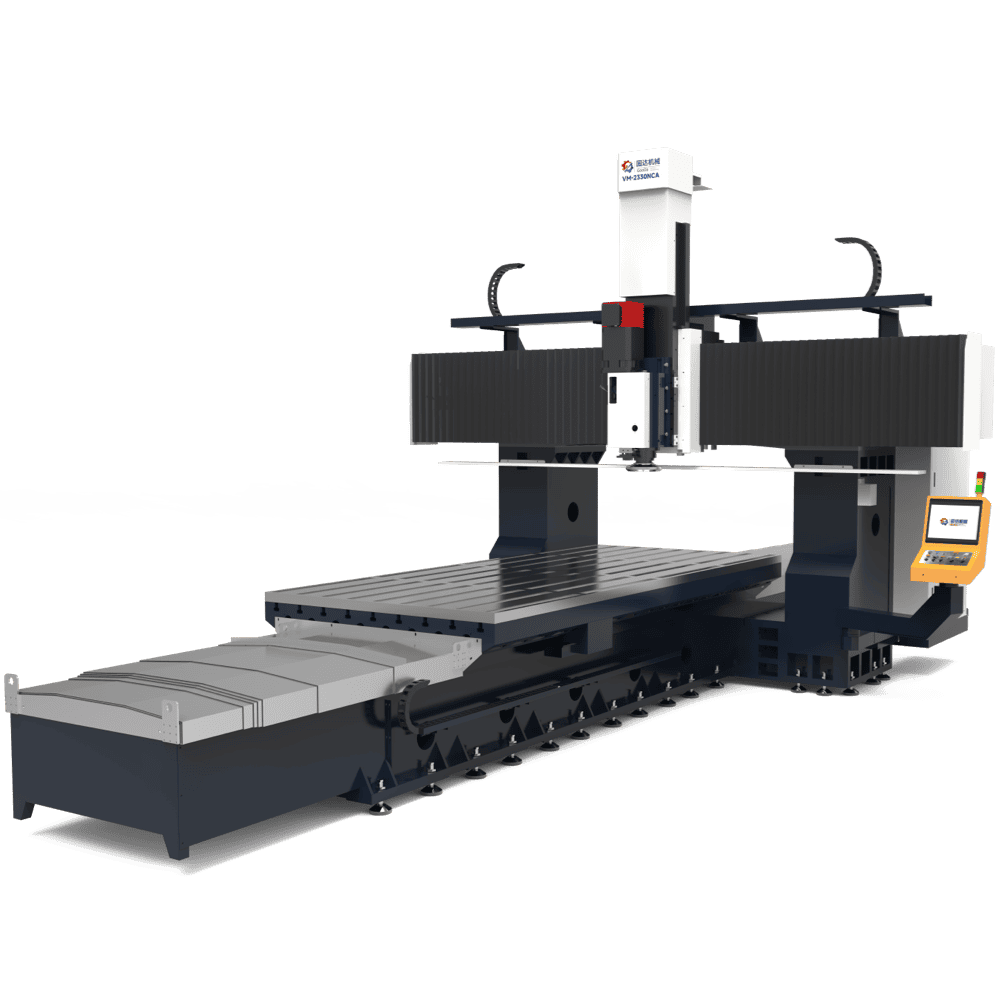

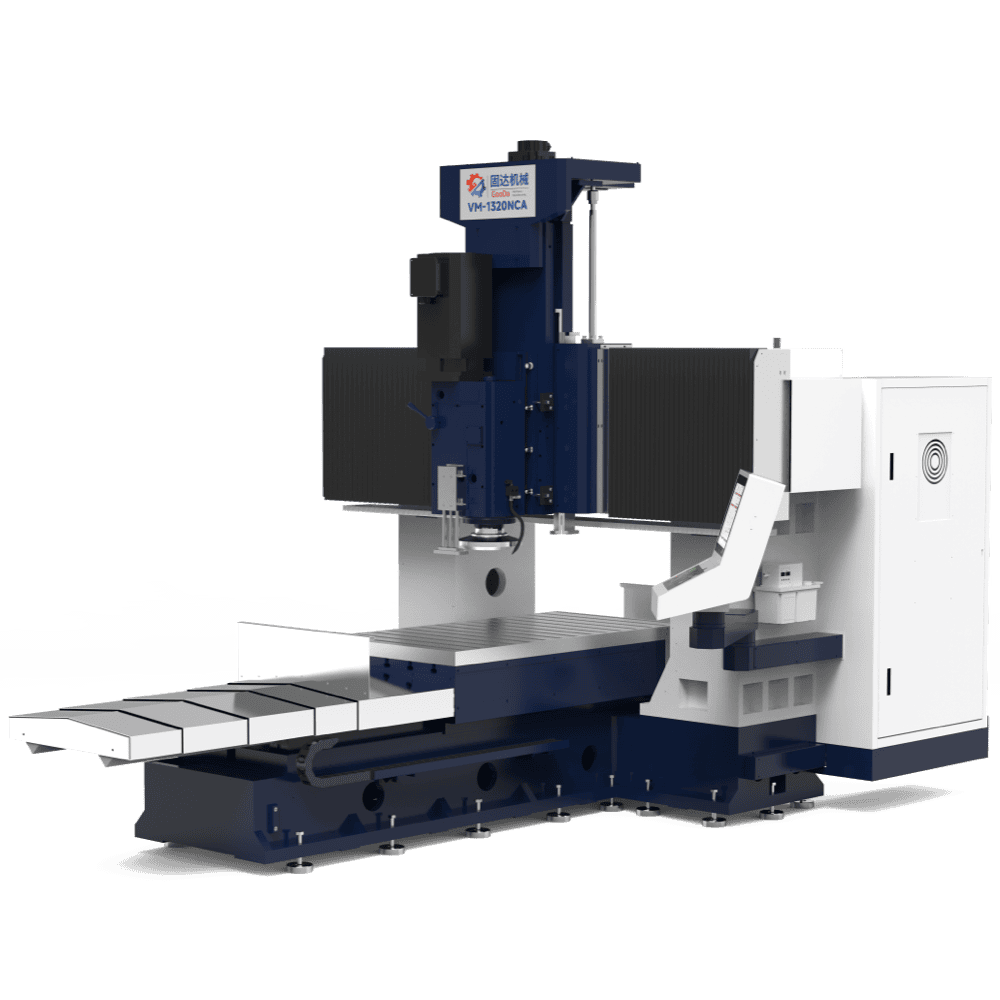

CNC Gantry Milling Machine

Process capacity:1800*3000mm. Gear box type spindles with high torque spindle motors.

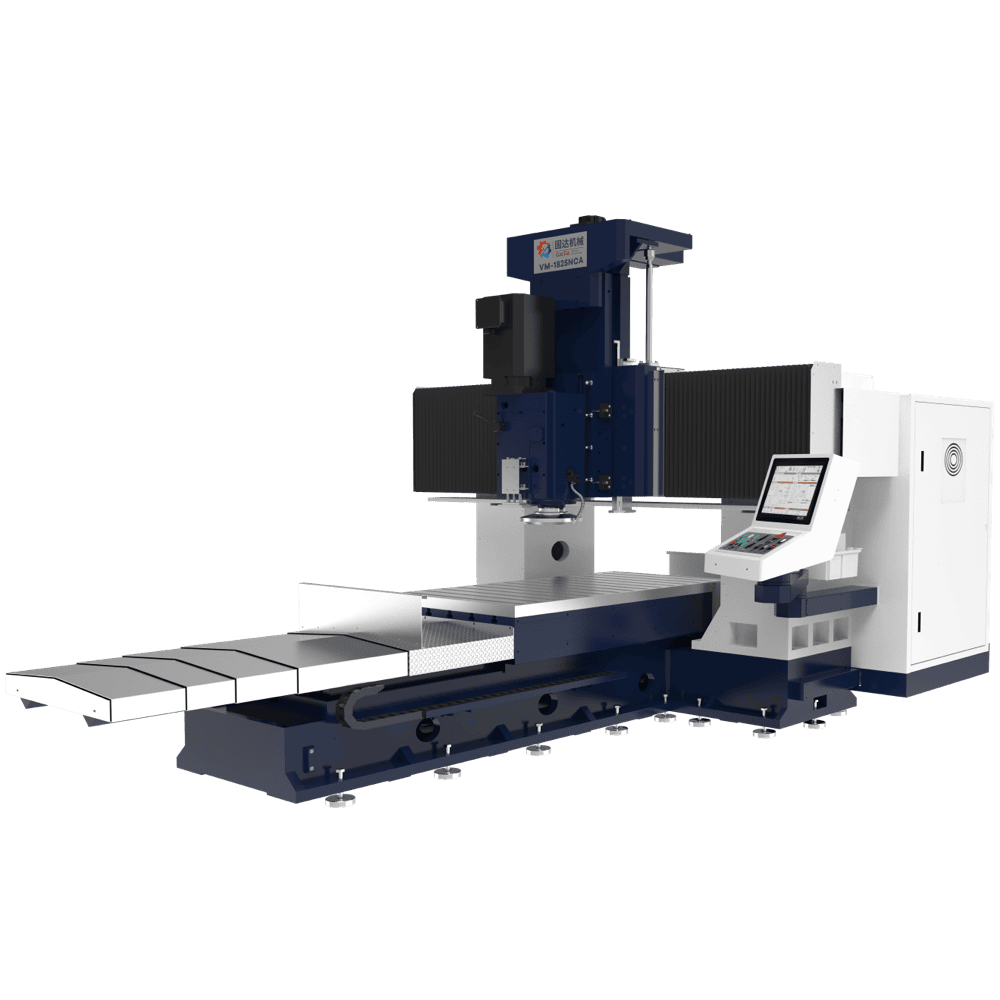

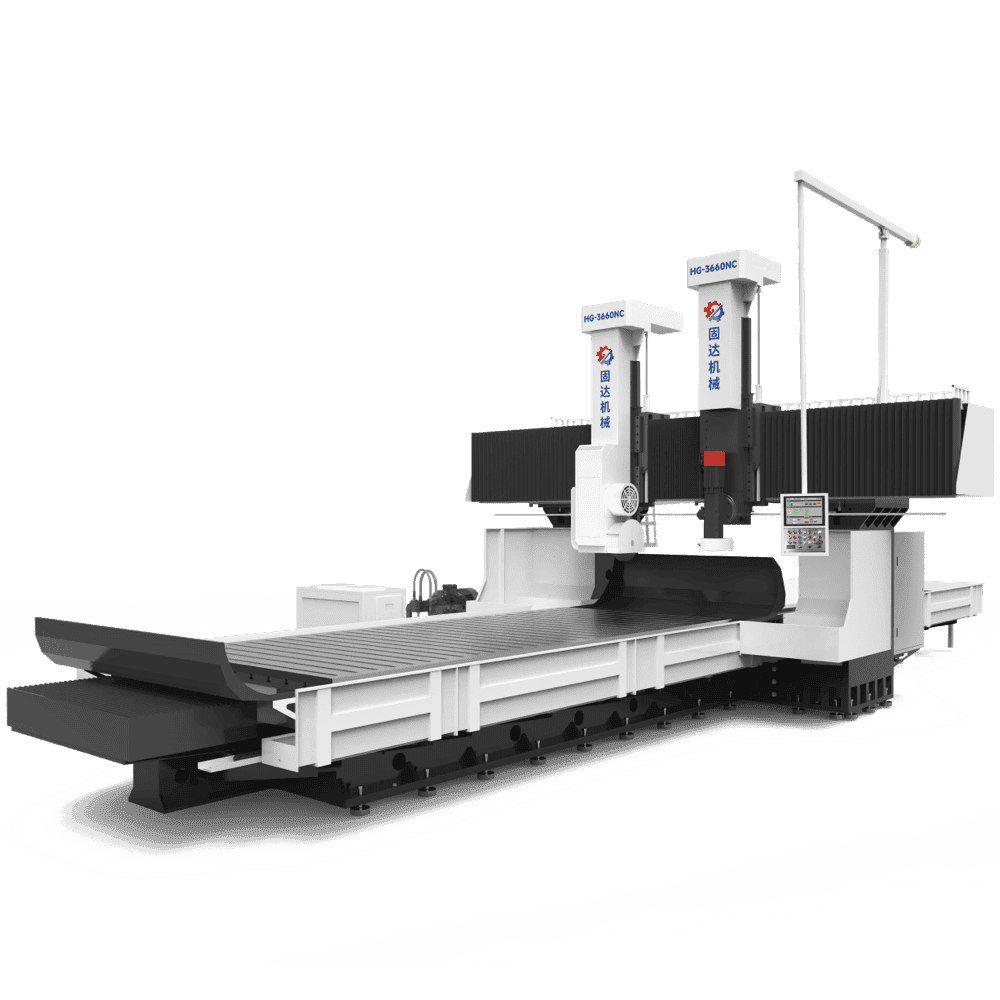

CNC Gantry Milling Machine

Process capacity:1400*2500mm. Gear box type spindles with high torque spindle motors.

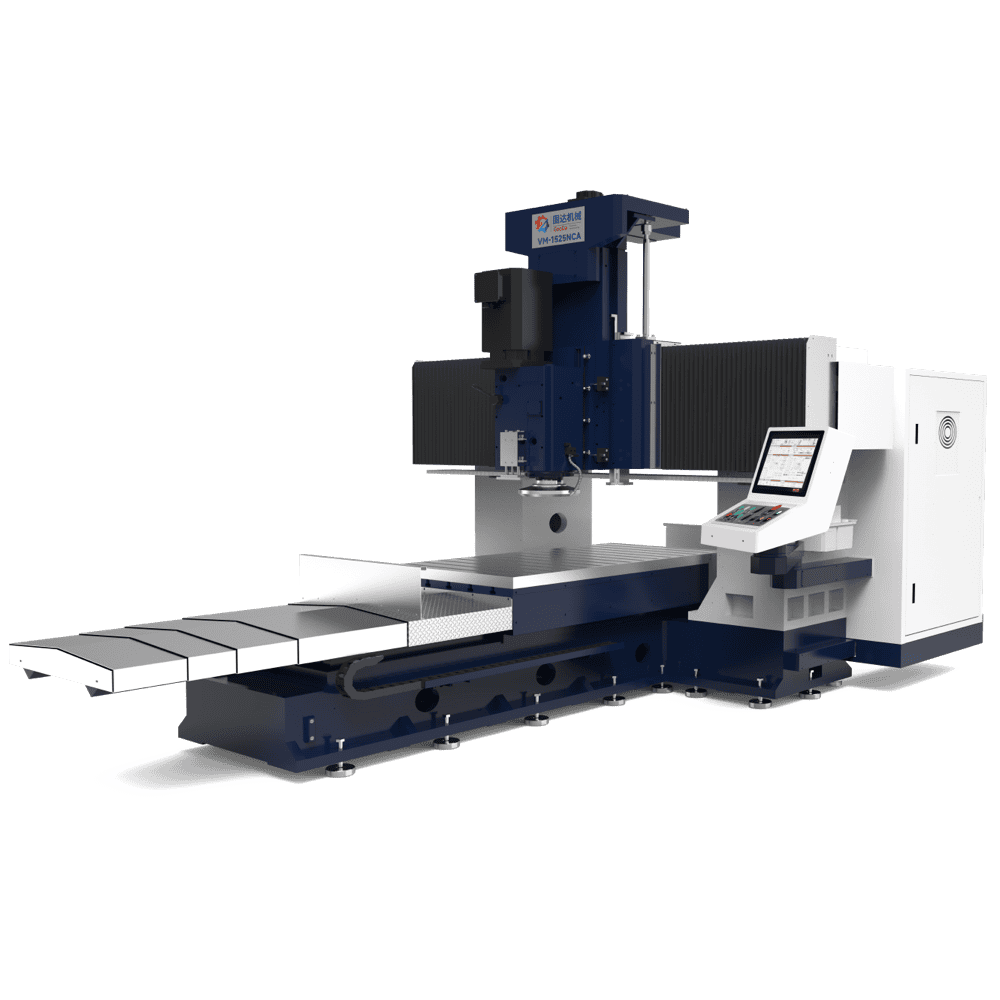

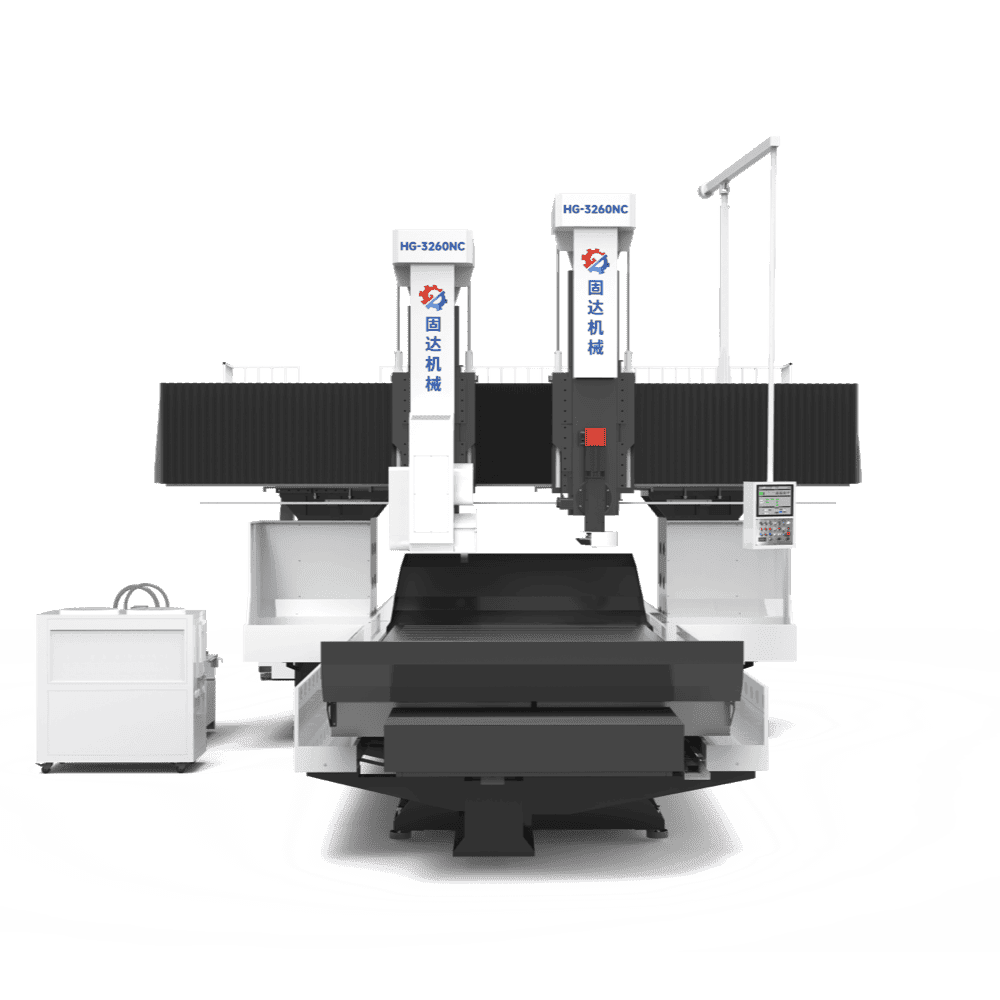

CNC Gantry Milling Machine

Process capacity:1200*2500mm. Gear box type spindles with high torque spindle motors.

CNC Gantry Milling Machine

Process capacity:1200*2000mm. Gear box type spindles with high torque spindle motors.

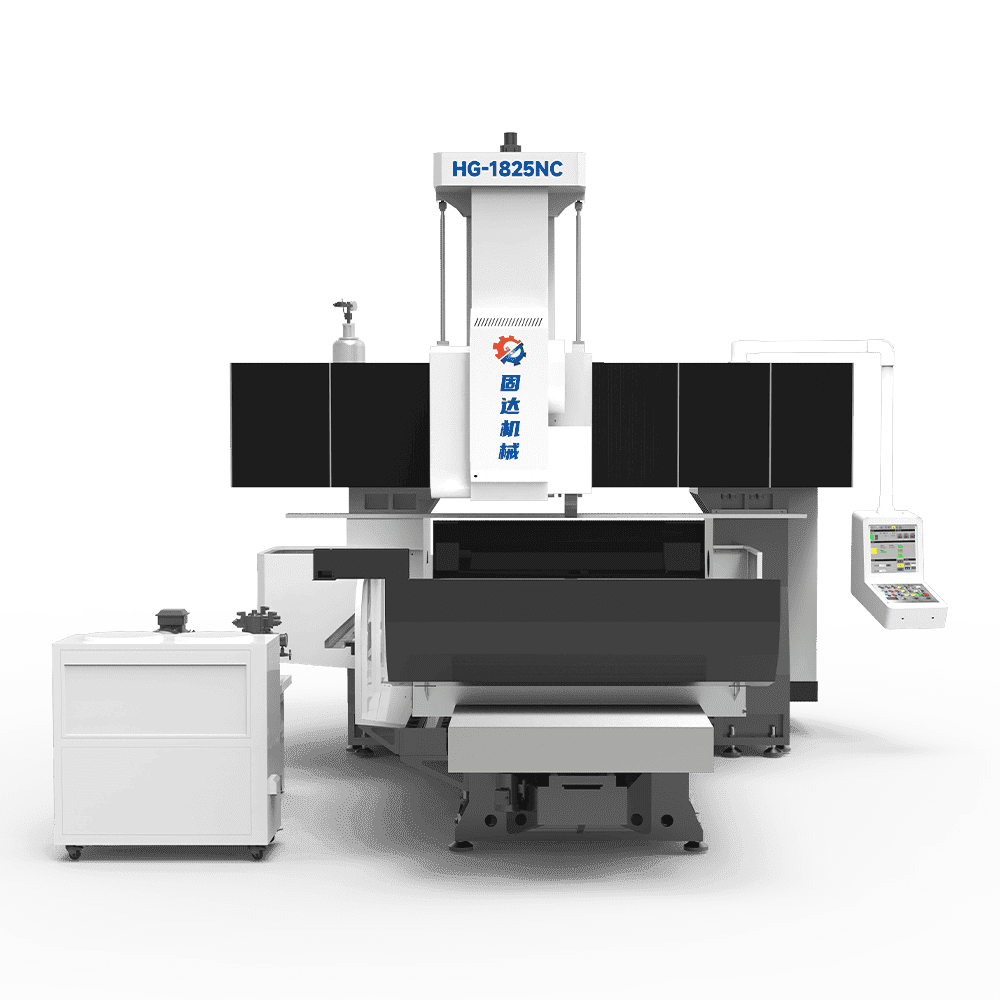

CNC Gantry Milling Machine

Process capacity:1200*2000mm. Gear box type spindles with high torque spindle motors.

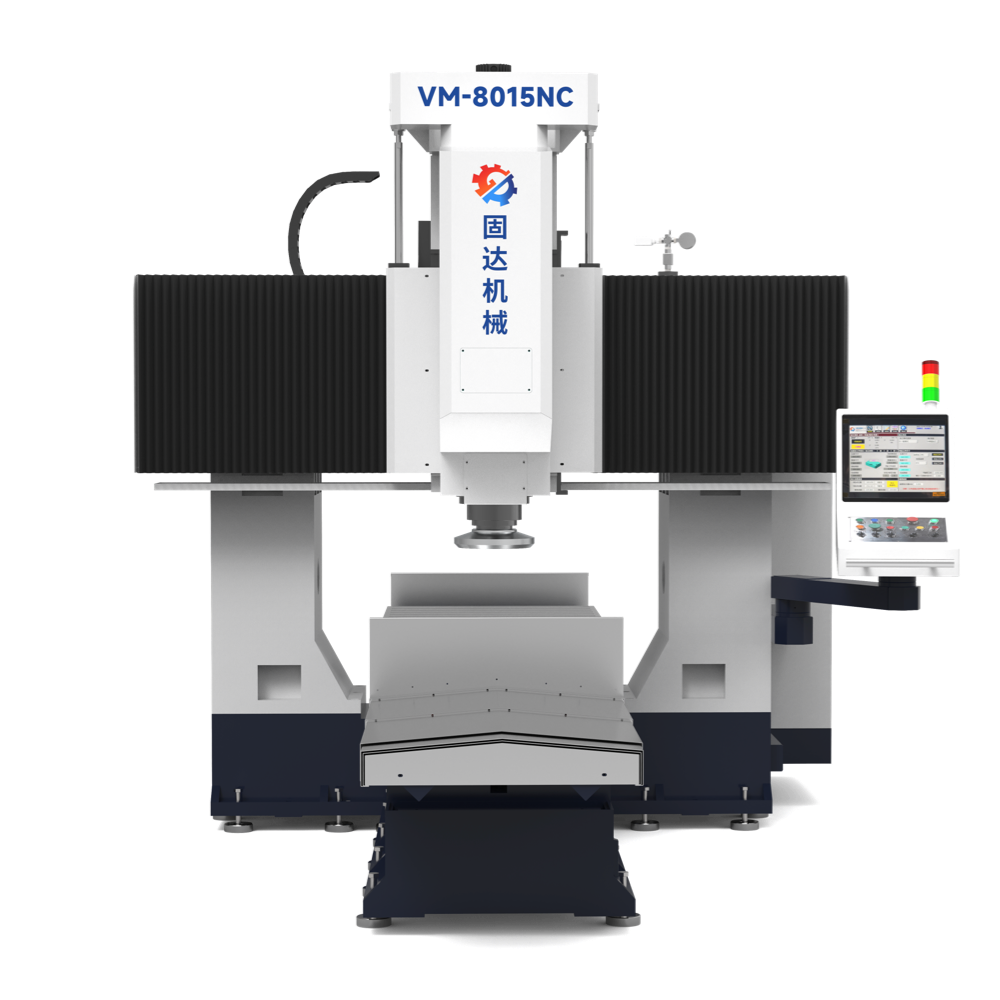

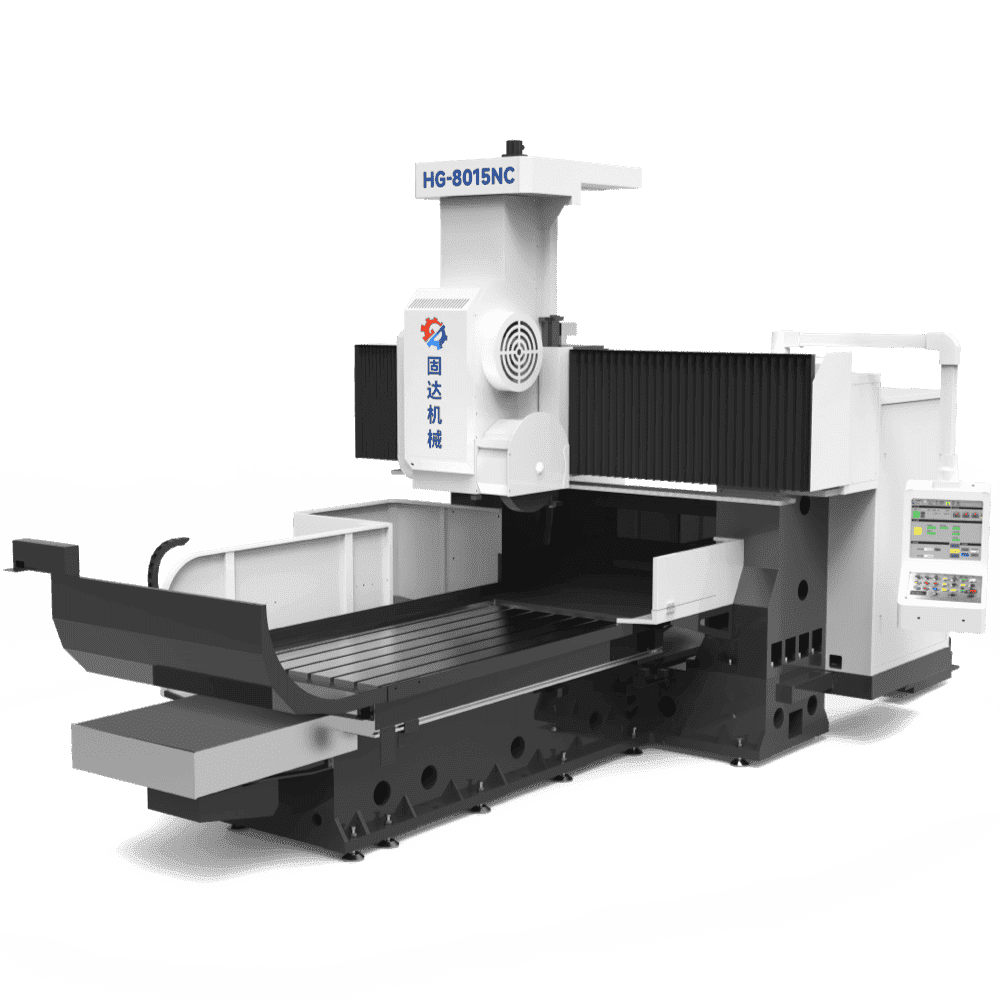

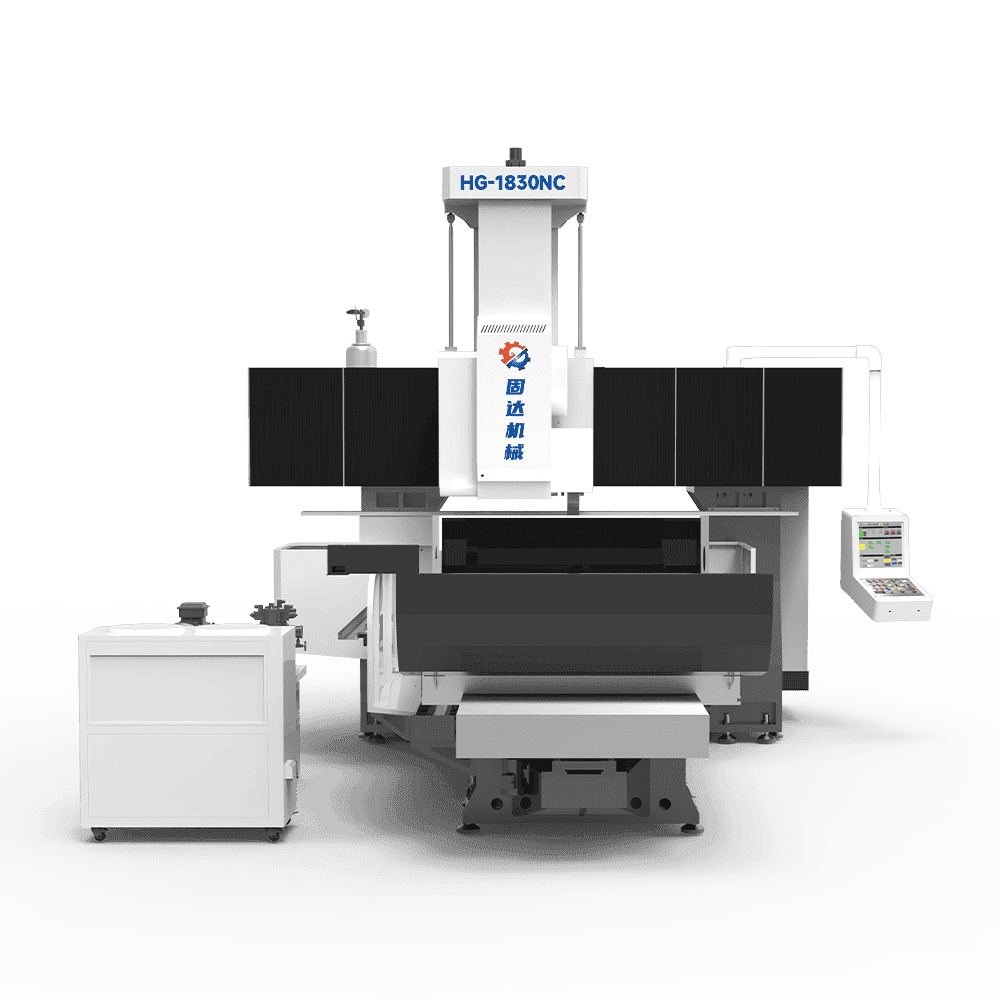

CNC Gantry Milling Machine

Process capacity:800*1500mm. Gear box type spindles with high torque spindle motors.

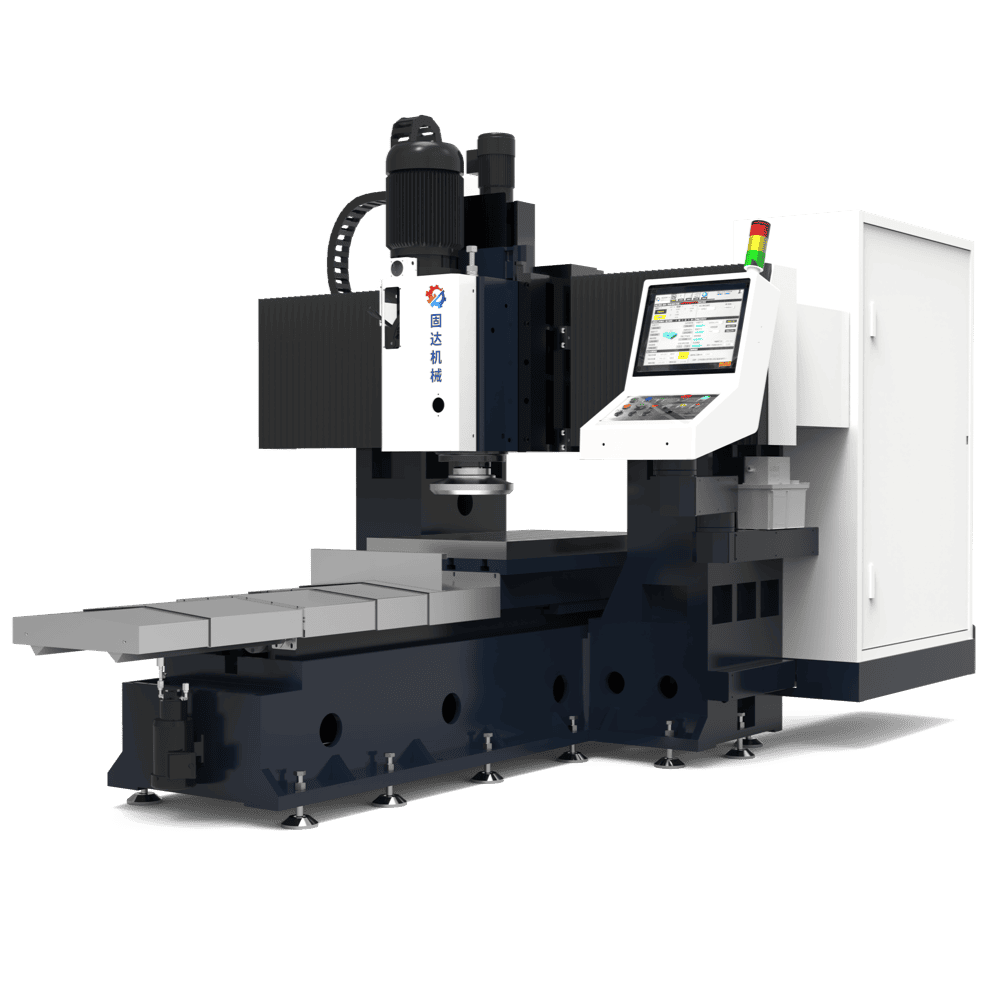

CNC Gantry Milling Machine

Process capacity:600*1000mm. Gear box type spindles with high torque spindle motors.

CNC Vertical Milling Machine

Process capacity:1000*600mm One-timedata setting, automatic positioning & measurement,automatic processing.

CNC Gantry Machining Center

Process capacity:245*500mm One-timedata setting, automatic positioning & measurement,automatic processing.

CNC Gantry Machining Center

Process capacity:390*800mm One-timedata setting, automatic positioning & measurement,automatic processing.

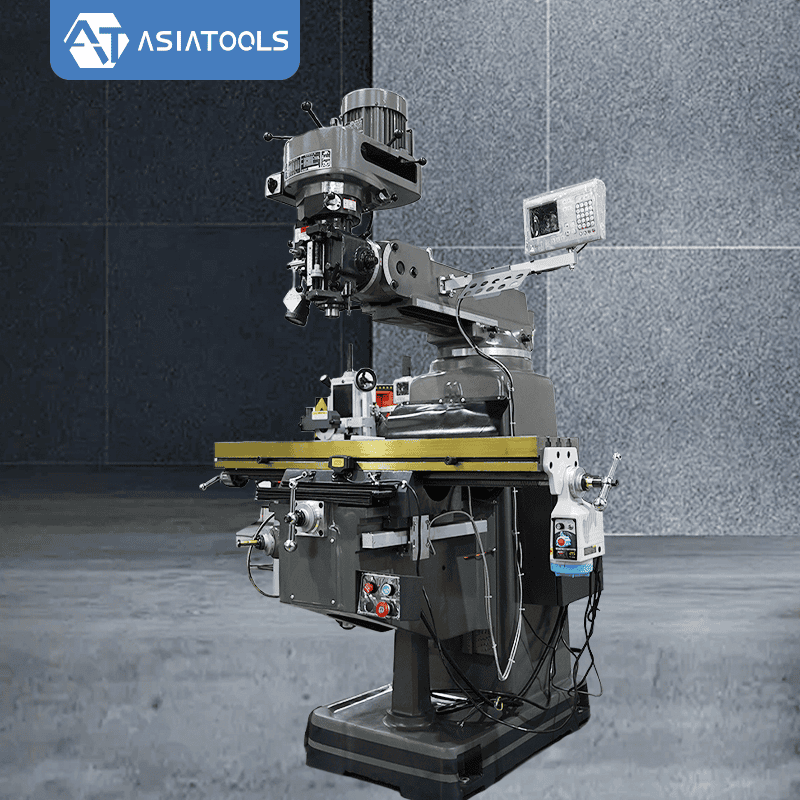

Turret Milling Machine

Spindle speed: 80-5440 rpm Its universally tilting head can tilt from 90° to the left and right, and 45° forward and backward, providing flexible positioning.

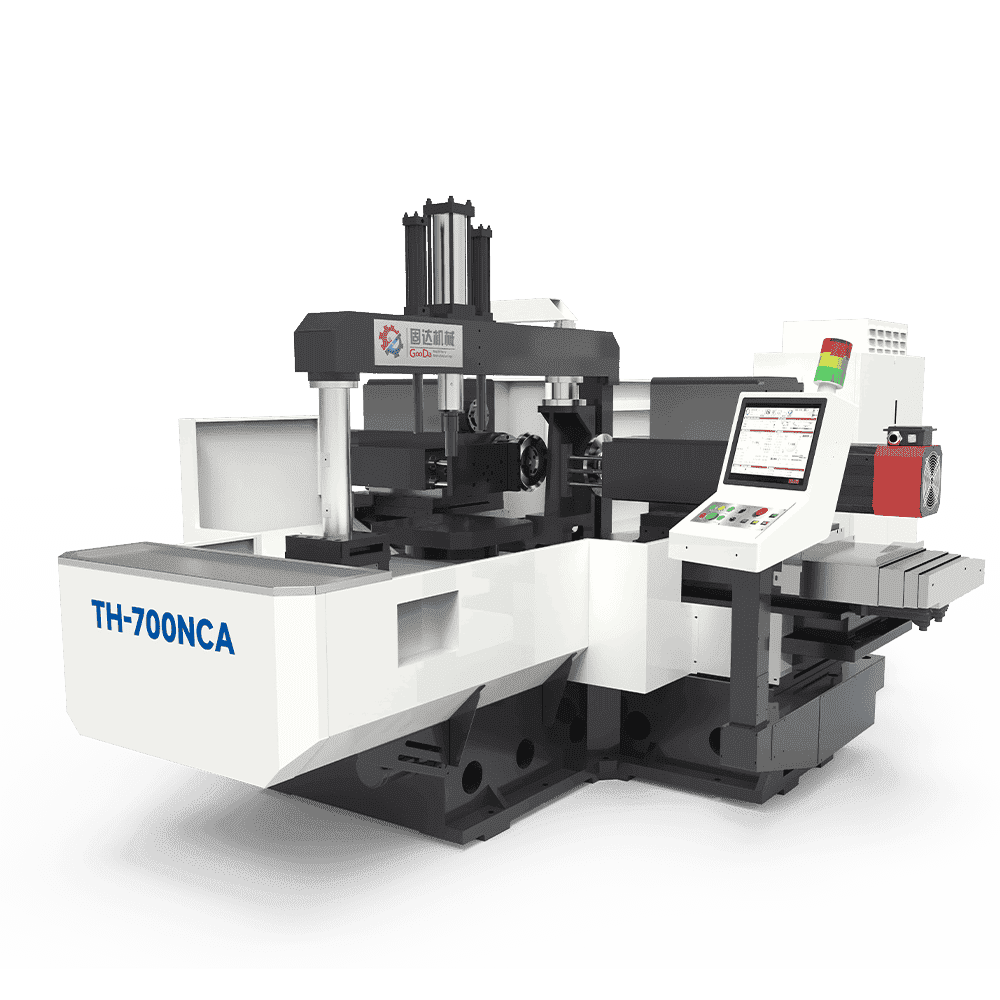

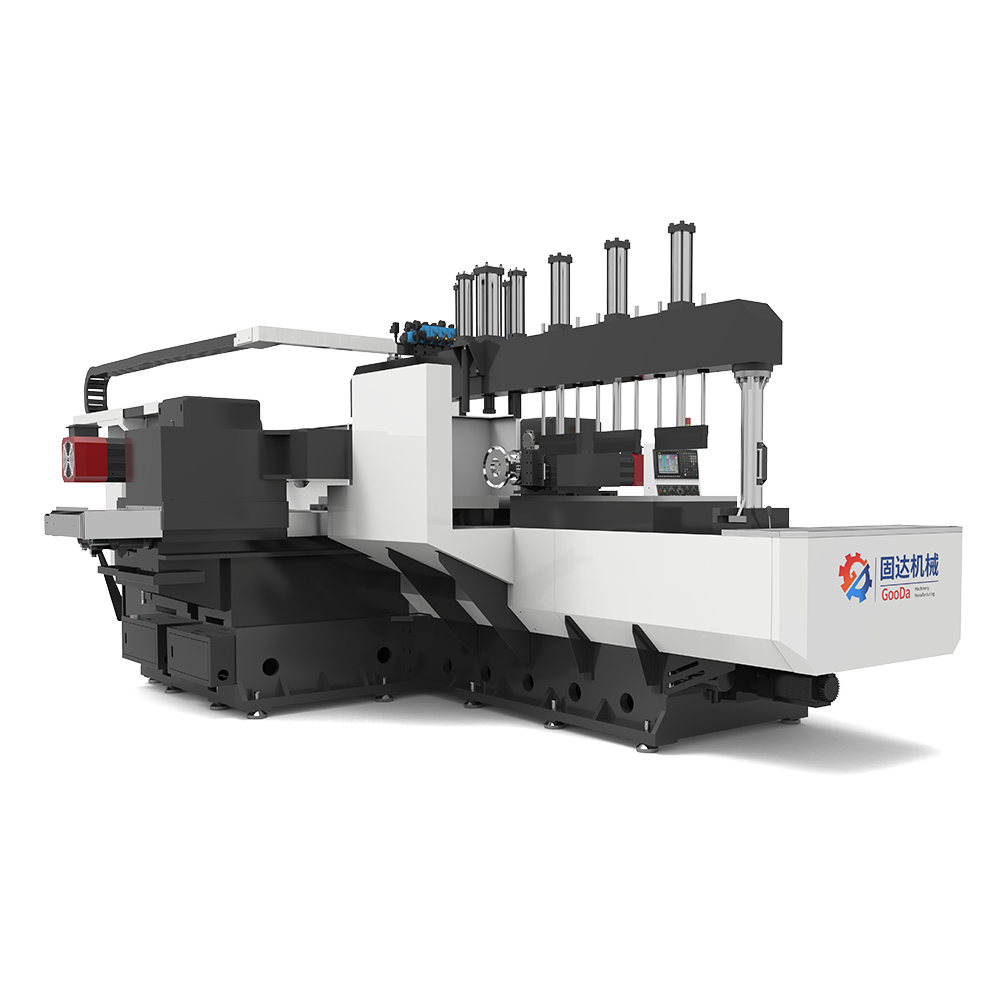

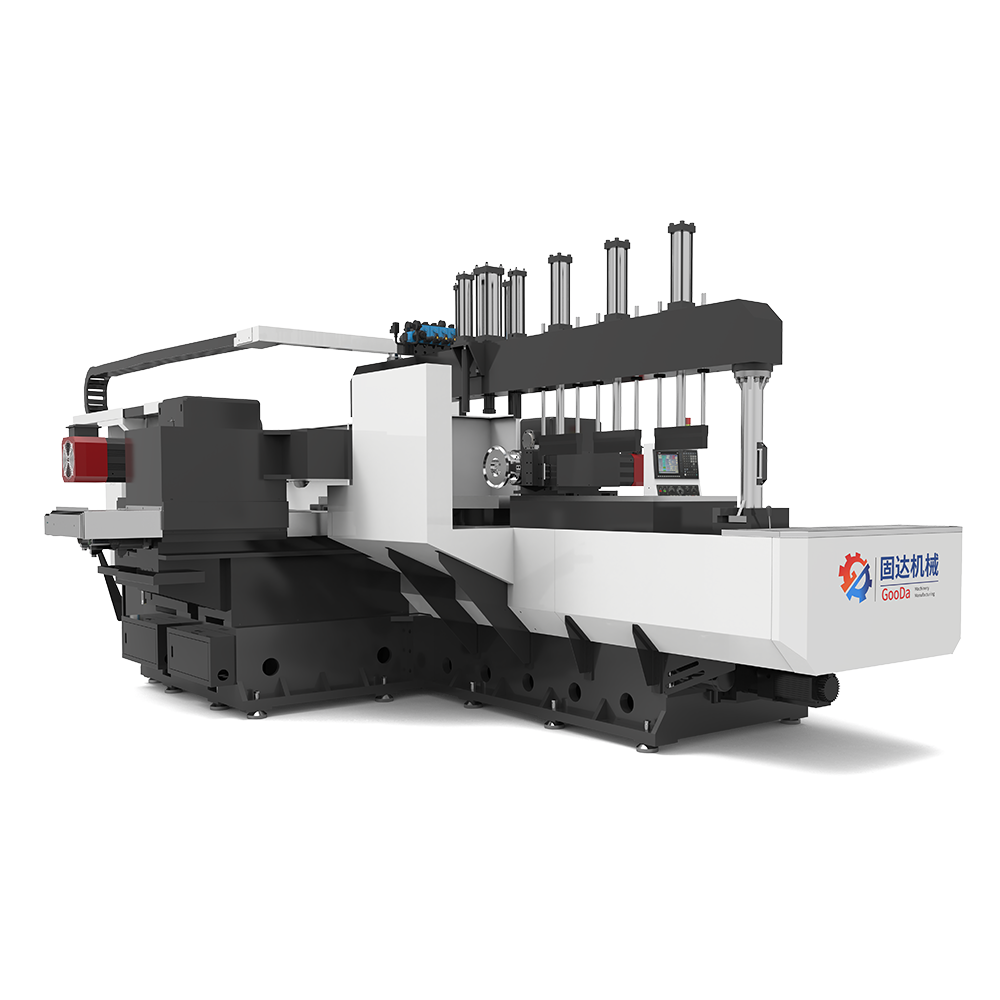

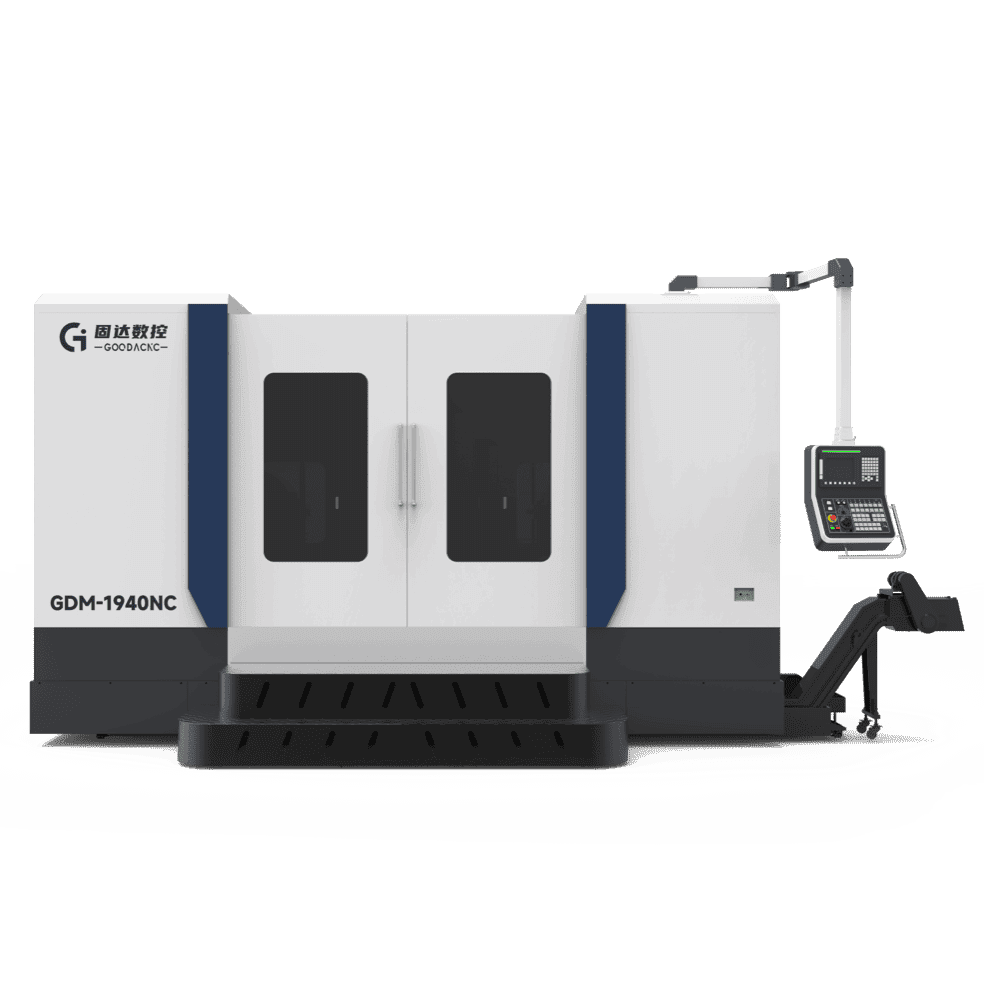

CNC Duplex Milling Machine

Process capacity:20-350mm. Complete four sides machining from rough milling to finished milling.

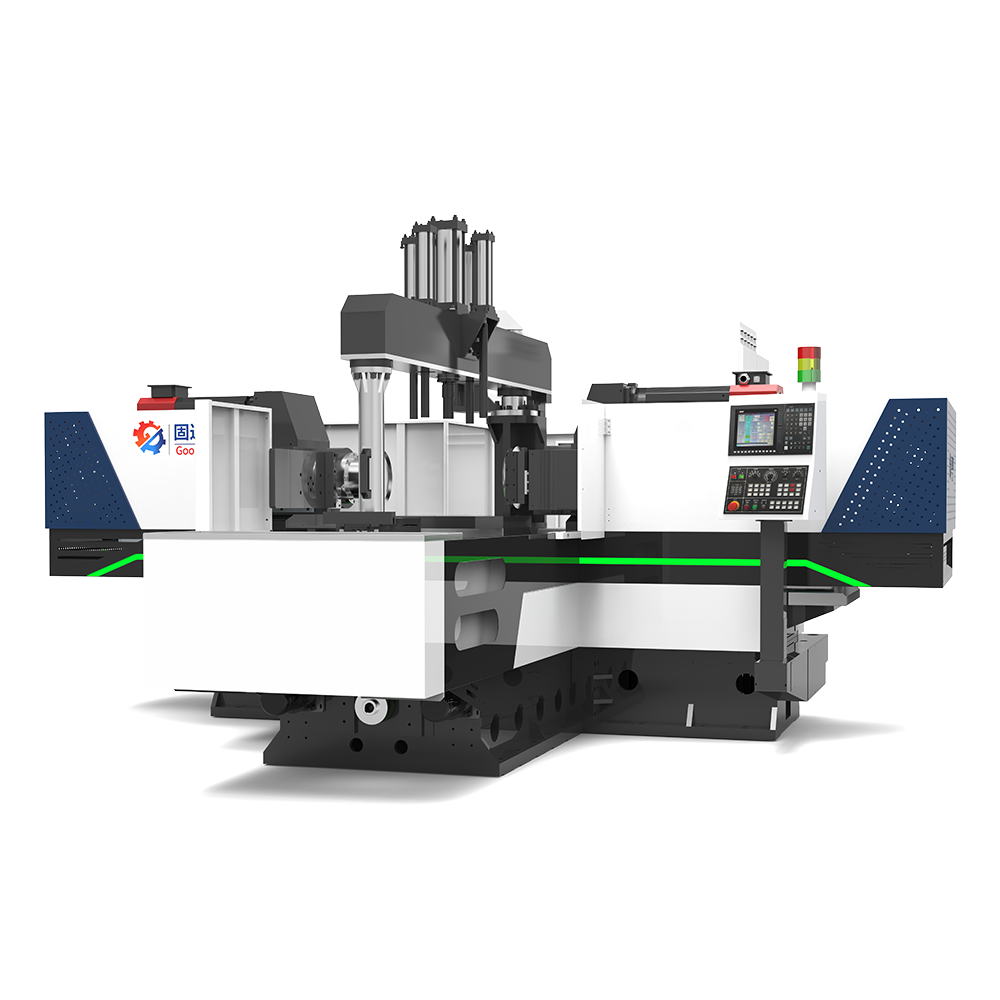

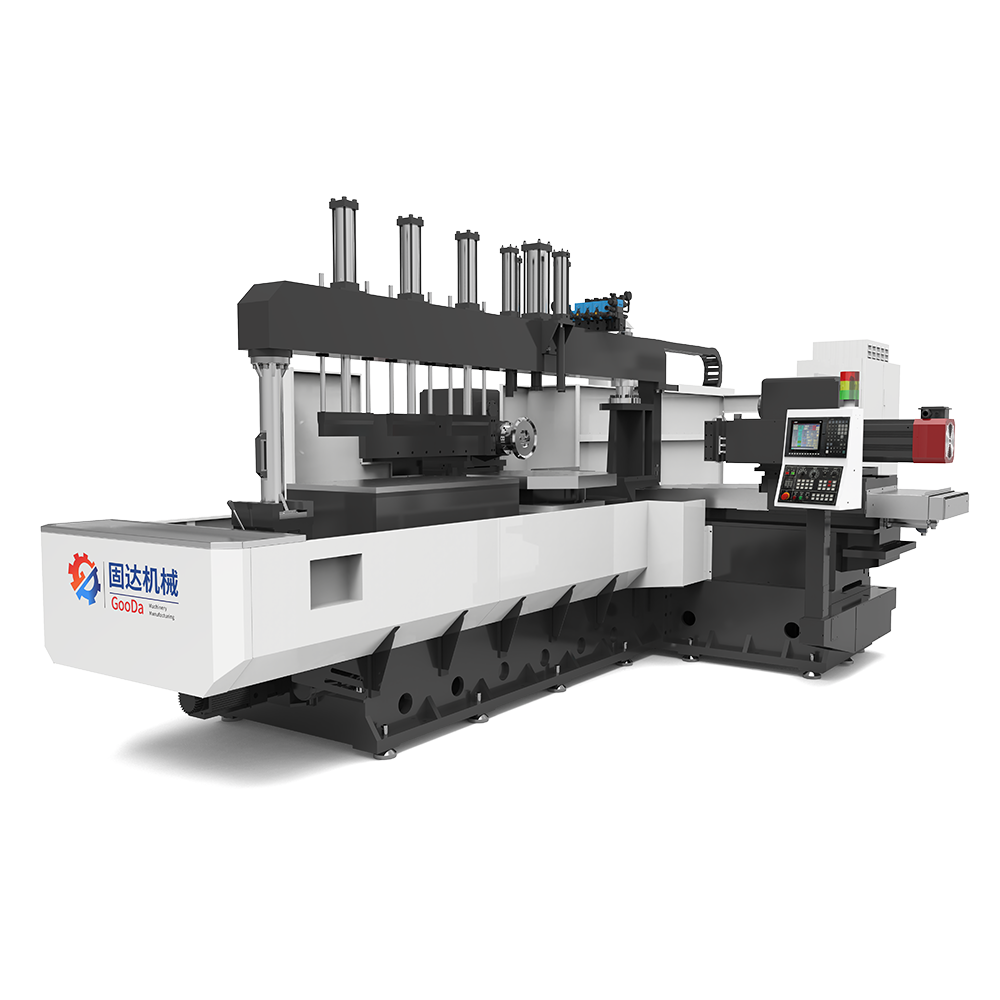

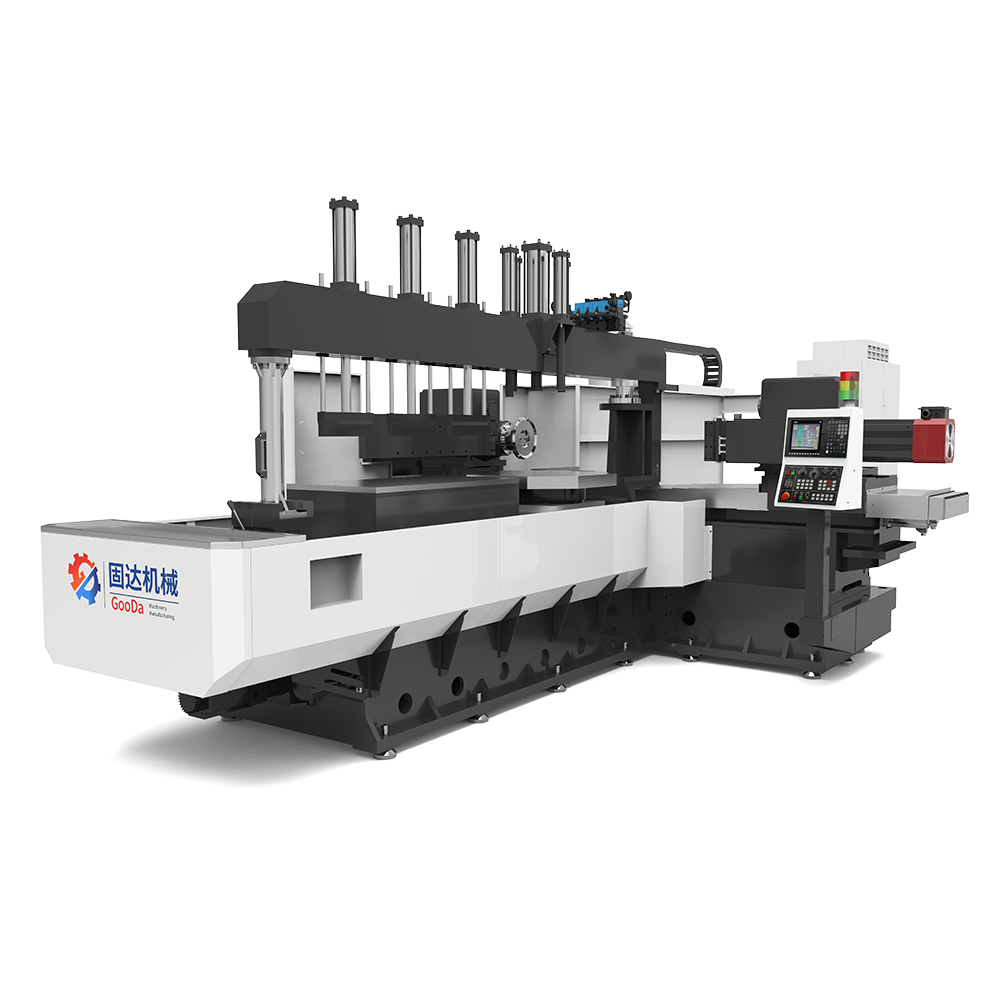

CNC Duplex Milling Machine

Process capacity:20-430mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:20-450mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:30-600mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:30-700mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:60-850mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:800-1000mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:150-1300mm. Complete four sides machining from rough milling to finished milling.

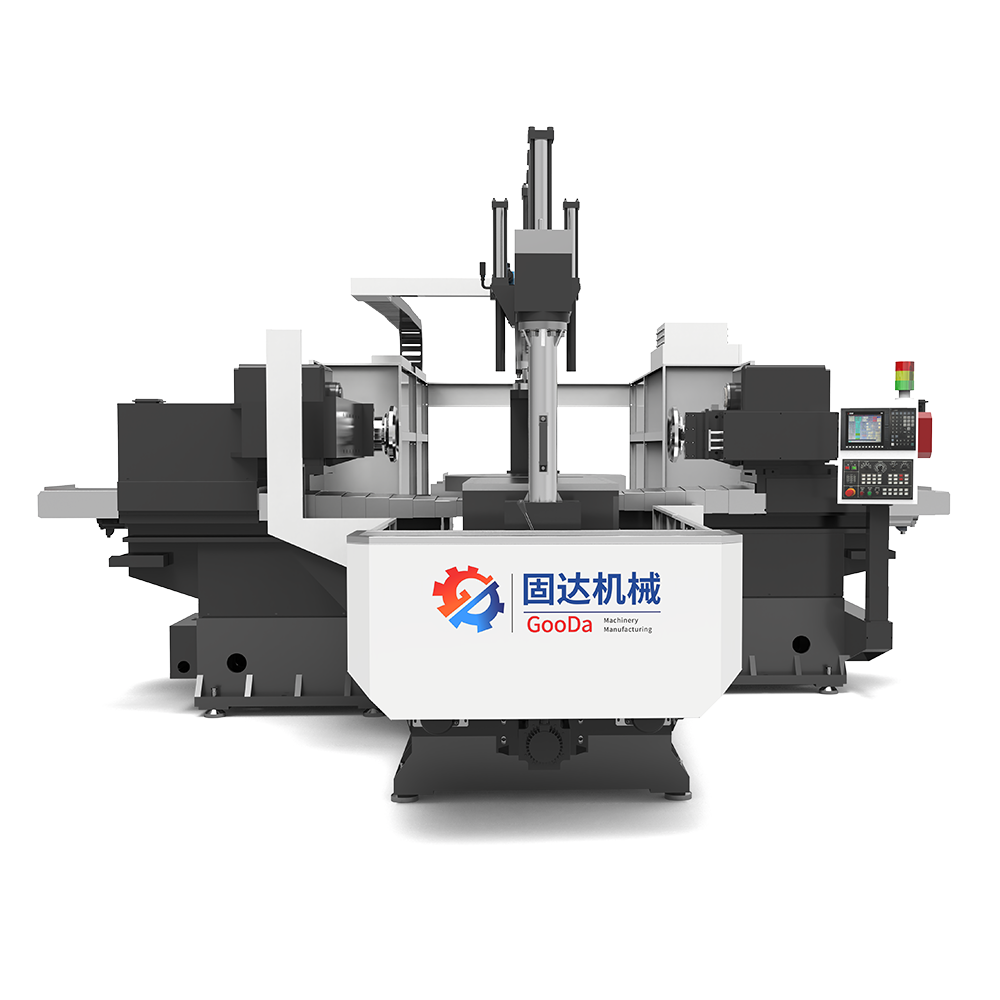

CNC Duplex Milling Machine

Process capacity:200-1500mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:200-1600mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:100-1300mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:700-1300mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:700-1500mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:850-1500mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Process capacity:1300-2500mm. Complete four sides machining from rough milling to finished milling.

CNC Duplex Milling Machine

Feed rate X/Y/Z:5000/2000/500mm/min Single-column lifting precision milling machine, with a large processing range of end milling machines.

CNC Duplex Milling Machine

Feed rate X/Y/Z:5000/2000/500mm/min Single-column lifting precision milling machine, with a large processing range of end milling machines.

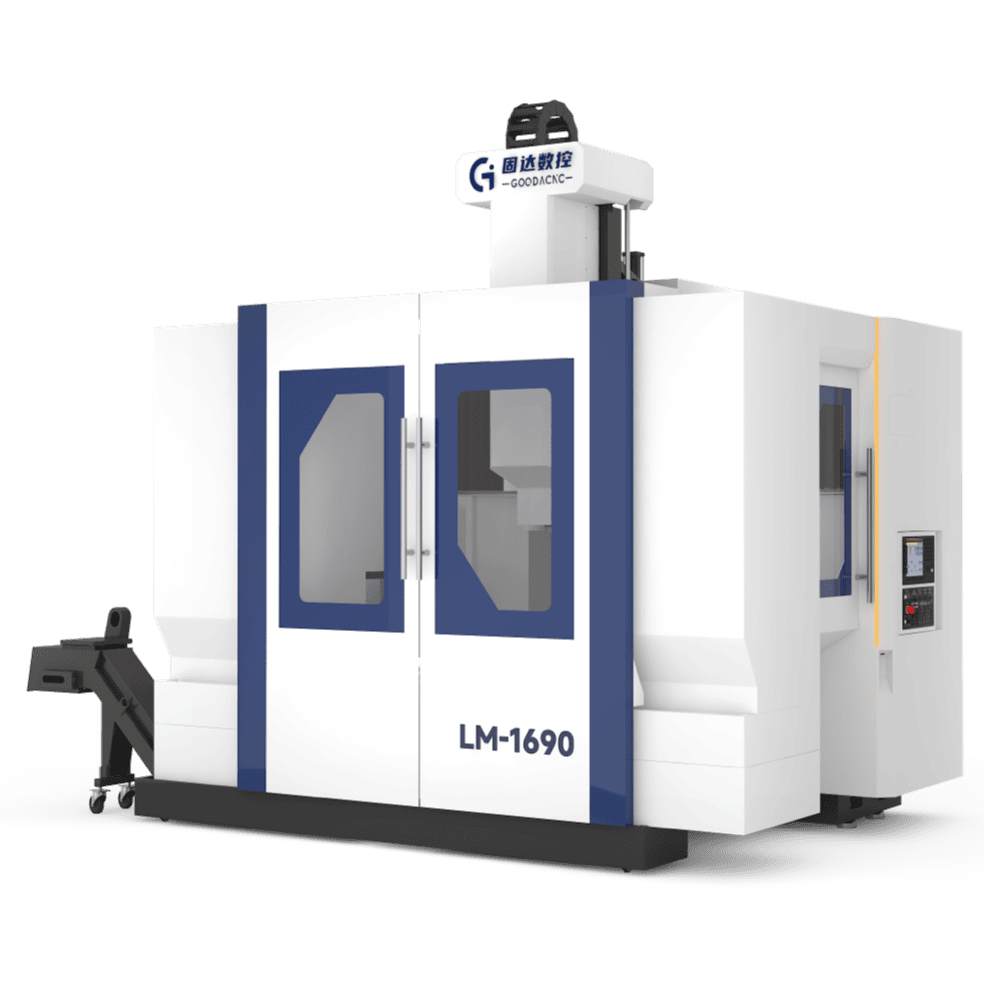

Vertical Machining Center

Feed speed (X*Y*Z-axis travel):800*500*500mm. Can provide single-setup complete part machining such as milling, drilling, boring, tapping, and thread milling.

Vertcal Machining Center

Feed speed (X*Y*Z-axis travel):1100*650*600mm. Can provide single-setup complete part machining such as milling, drilling, boring, tapping, and thread milling.

Vertcal Machining Center

Feed speed (X*Y*Z-axis travel):1200*700*700mm. Can provide single-setup complete part machining such as milling, drilling, boring, tapping, and thread milling.

Vertcal Machining Center

Feed speed (X*Y*Z-axis travel):1300*700*700mm. Suitable for machining parts such as medium and small-sized hardware, box, plate, disk, and shell-type components.

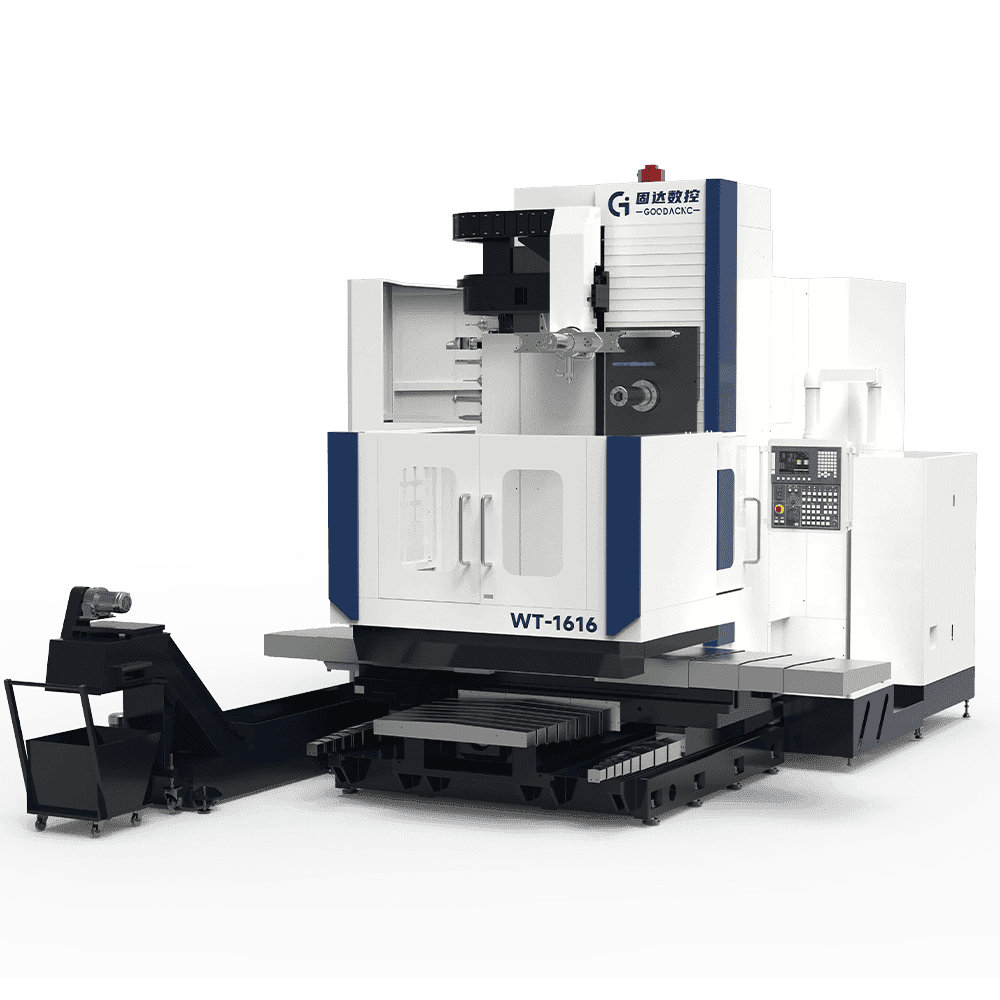

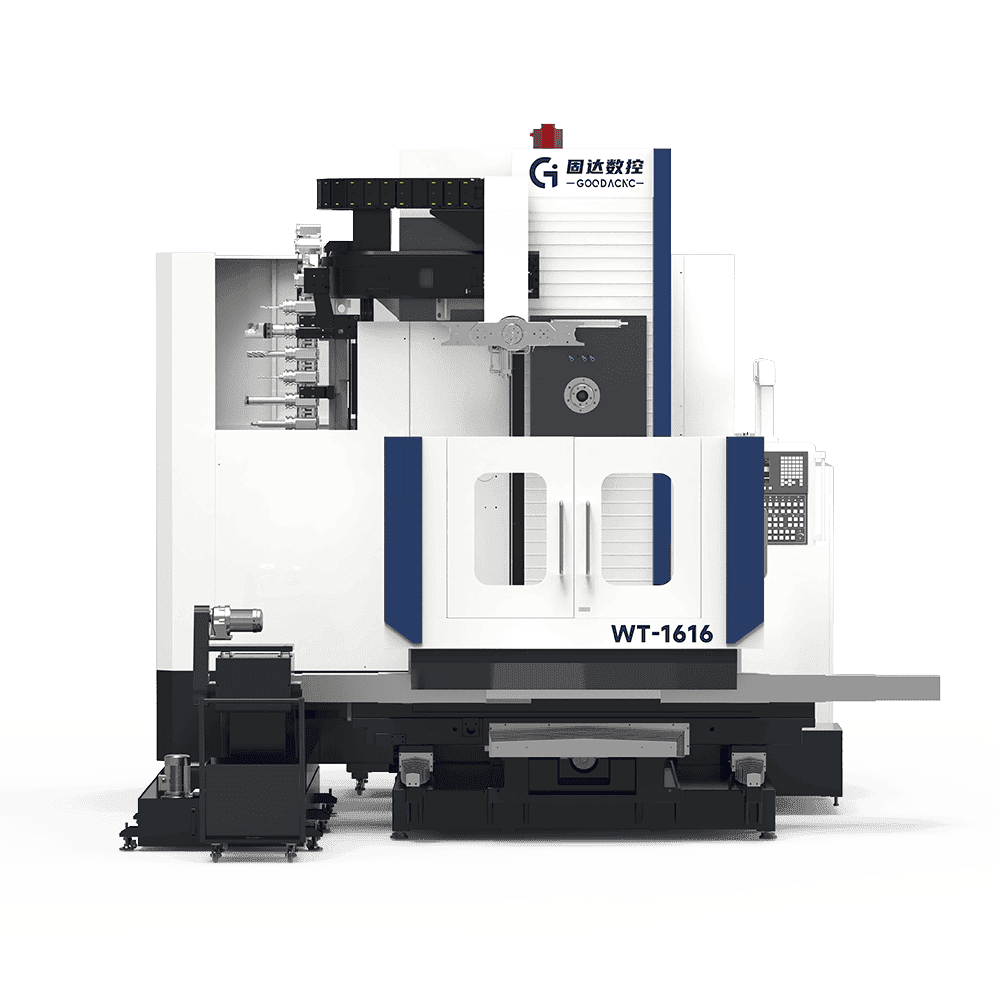

Double Column Machining Center

Travels X/Y/Z:1000/ 2000/800mm It comes standard with a Taiwan BT50-6000rpm spindle for both roughing and finishing operations.

Vertcal Machining Center

Travels X/Y/Z:1000/ 2000/800mm It integrates multiple processes including milling, boring, drilling, and tapping.

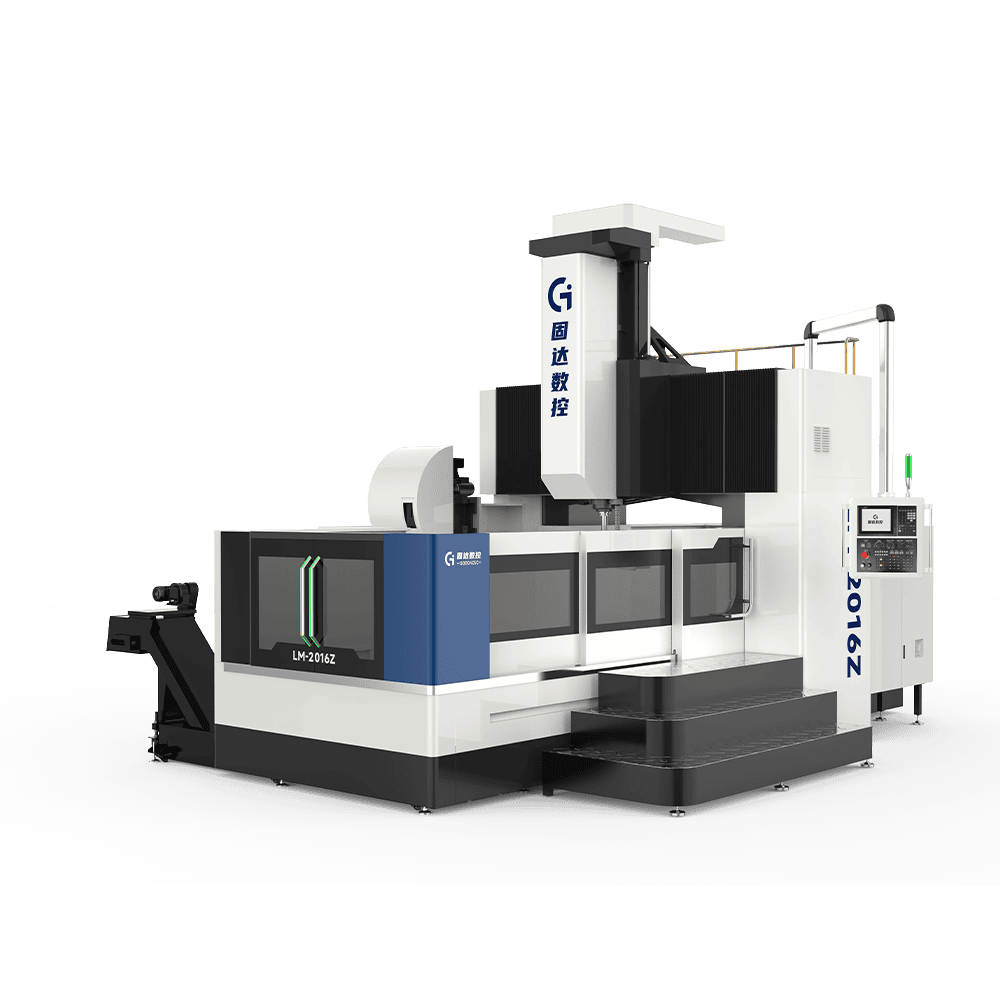

Vertcal Machining Center

Travels X/Y/Z:3000/2000/1000mm A single clamping of the workpiece can complete various processes such as milling, boring, drilling, and tapping.

Vertcal Machining Center

Travels X/Y/Z:3200/2760/1000mm A single clamping of the workpiece can complete various processes such as milling, boring, drilling, and tapping.

Twin Spindle Horinzontal Machining Center

Travels X/Y/Z:800/ 350/400mm It has multi-process processing technologies such as surface milling, driling and tapping, and can achieveone-time clamping & forming processing technology.

Twin Spindle Horinzontal Machining Center

Travels X/Y/Z:500/500/300mm It has multi-process processing technologies such as surface milling, driling and tapping, and can achieveone-time clamping & forming processing technology.

Twin Spindle Horinzontal Machining Center

Feed speed:8000mm/min It can achieve drilling through-holes and blind holes on single-material parts or composite materials, and can achieve large-scale production with automation and high precision.

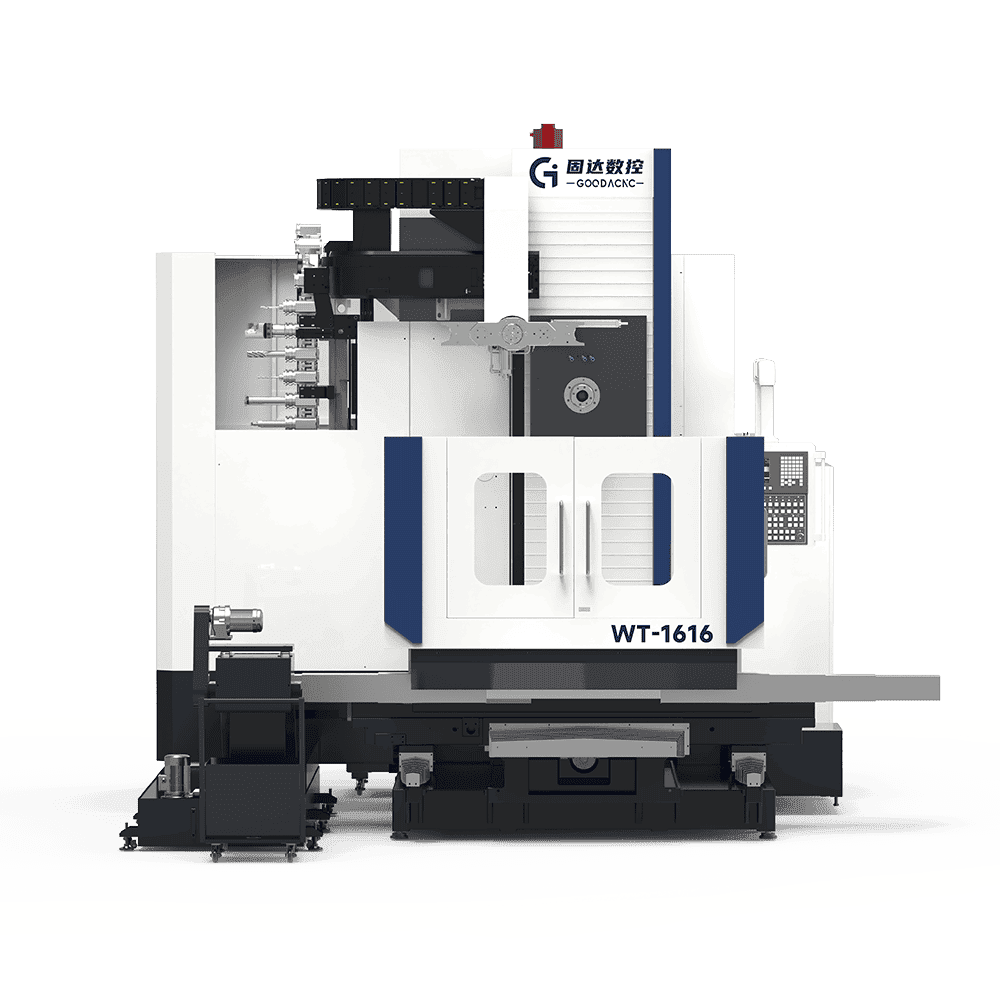

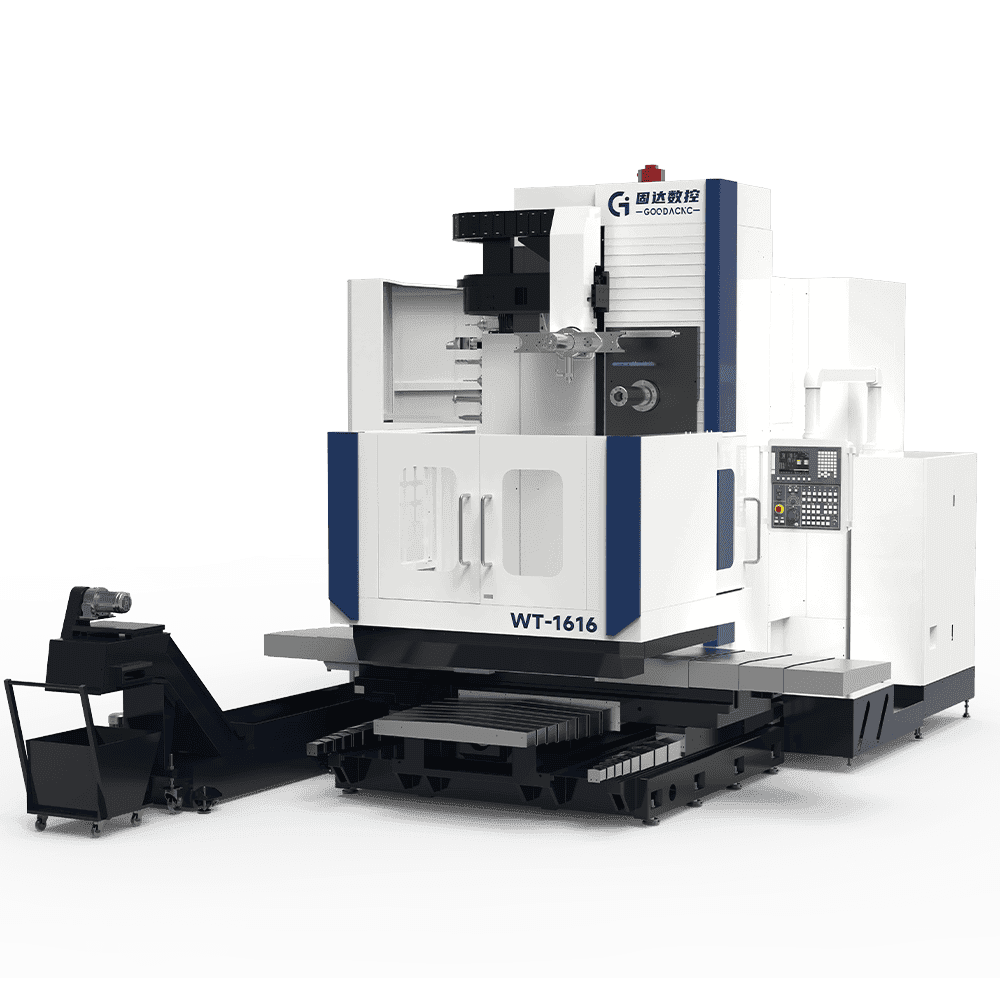

CNC Horizontal Machining Centers

Process capacity:1800*1500*850mm. It is heavy-duty cutting and heavy-load, and is a durable tool for rough and finish machining.

CNC Horizontal Machining Centers

Process capacity:2000*1500*850mm. It is heavy-duty cutting and heavy-load, and is a durable tool for rough and finish machining.

CNC Horizontal Machining Centers

Process capacity:2500*1500*850mm. It is heavy-duty cutting and heavy-load, and is a durable tool for rough and finish machining.

CNC Horizontal Machining Centers

Process capacity:3000*1500*850mm. The machine tool adopts floor-type structure with an X-axis moving column, surrounded by guideways on three sides.

CNC Horizontal Machining Centers

Process capacity:3000*2000*850mm. The machine tool adopts floor-type structure with an X-axis moving column, surrounded by guideways on three sides.

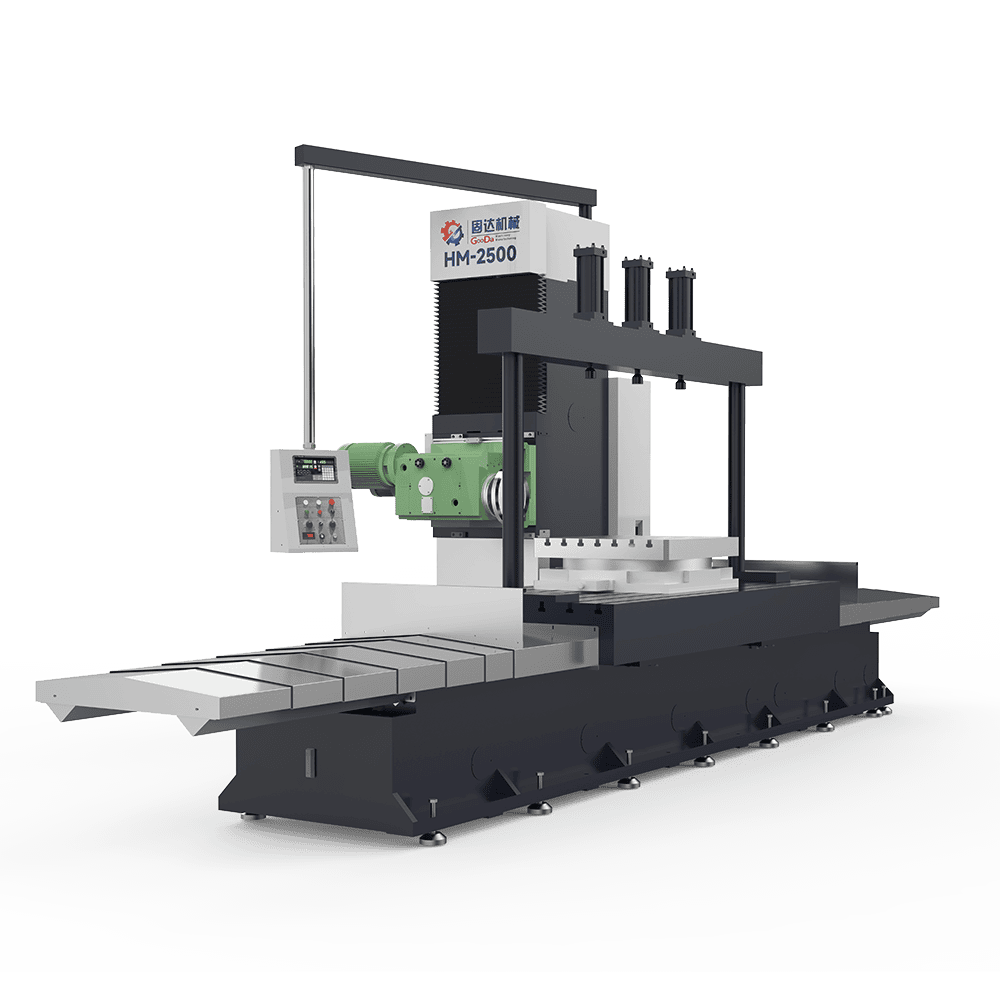

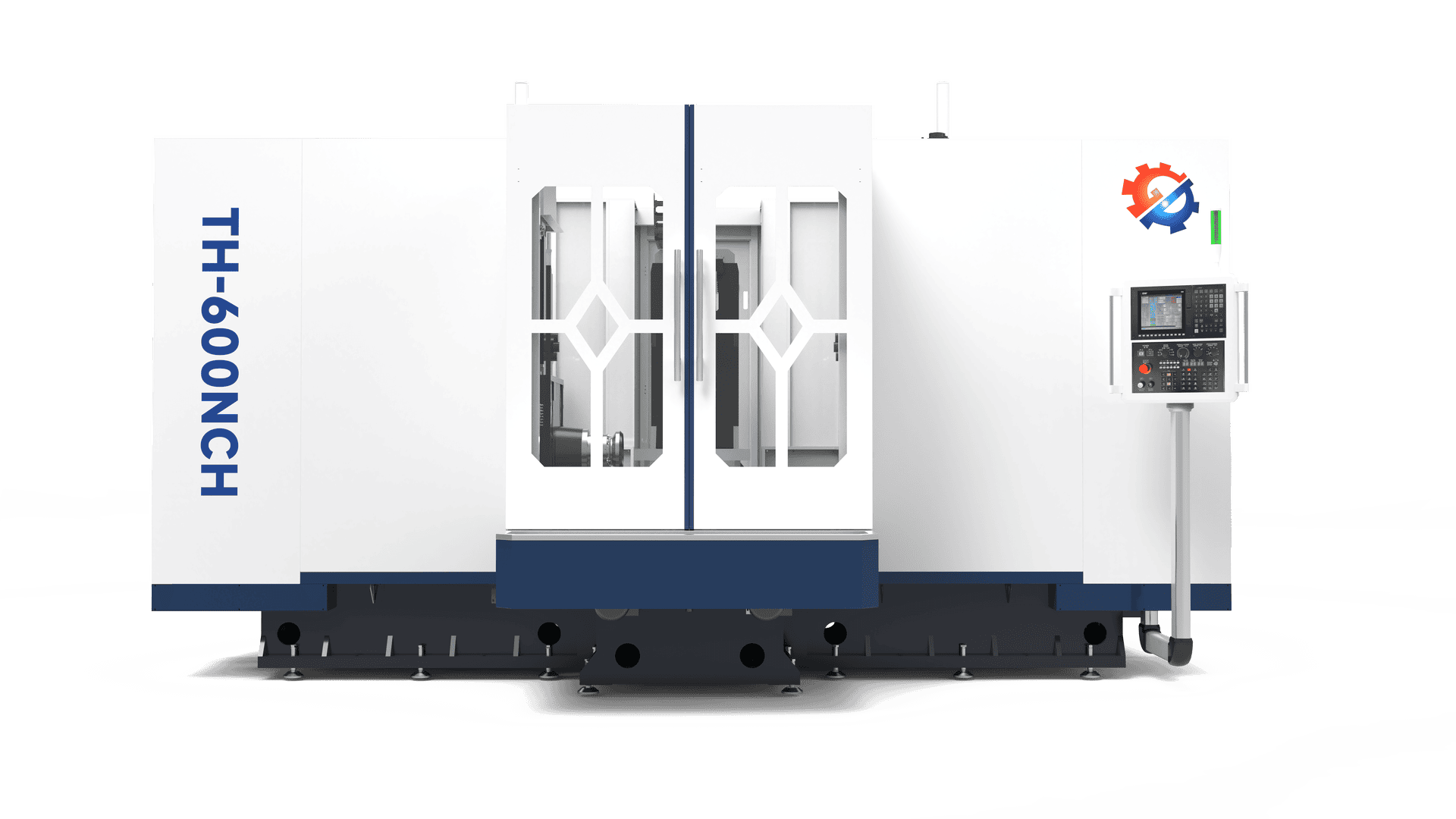

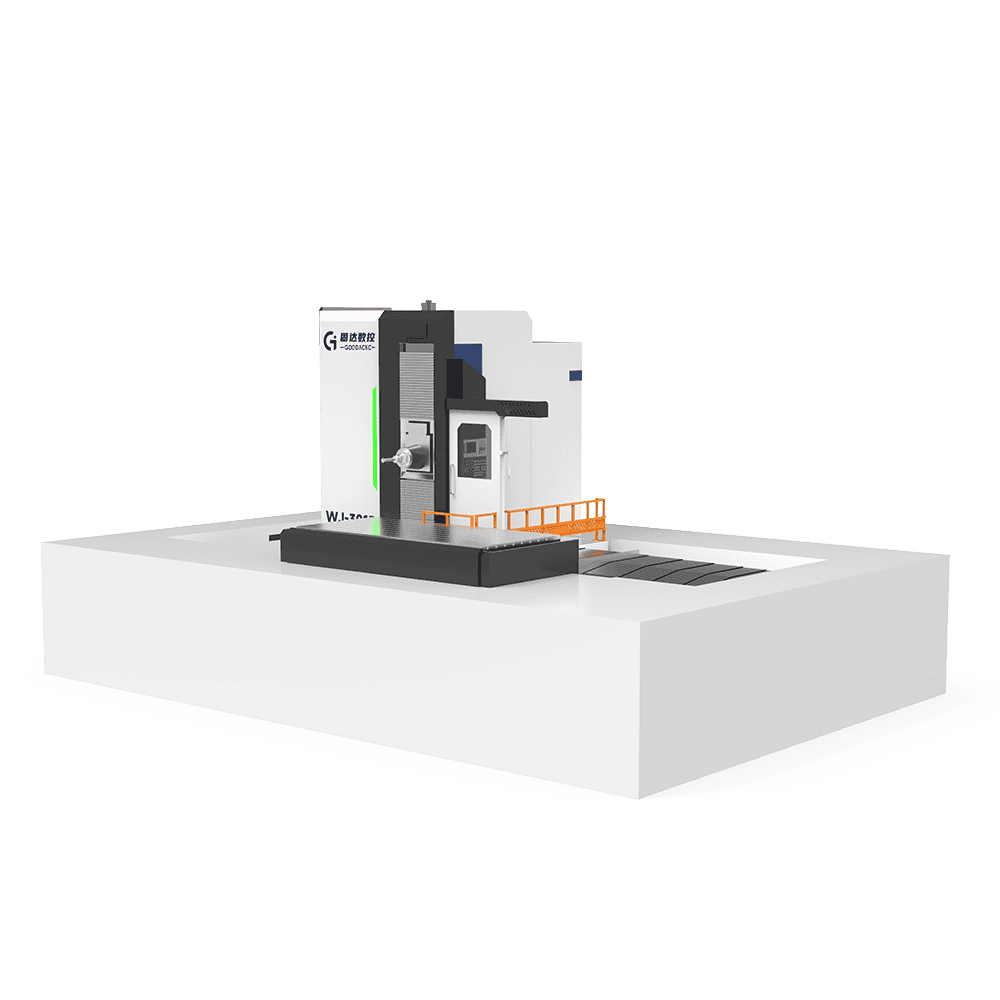

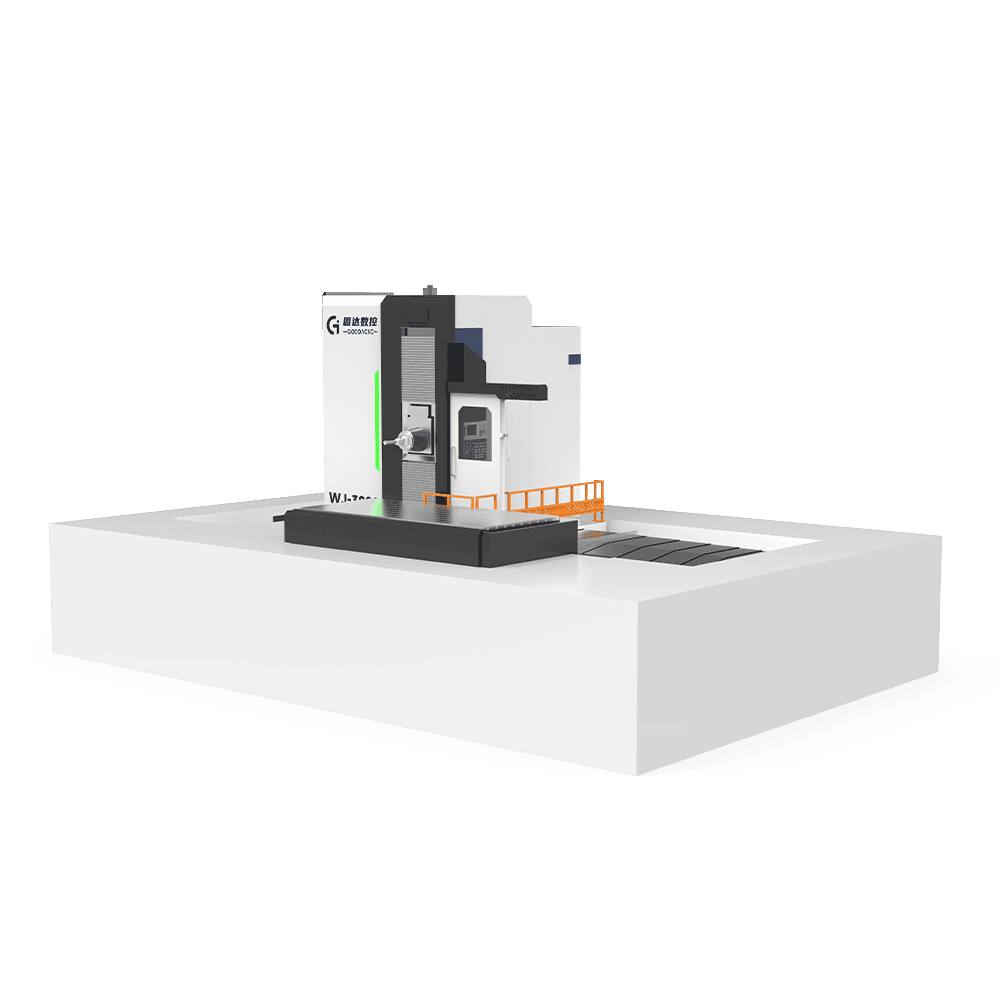

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

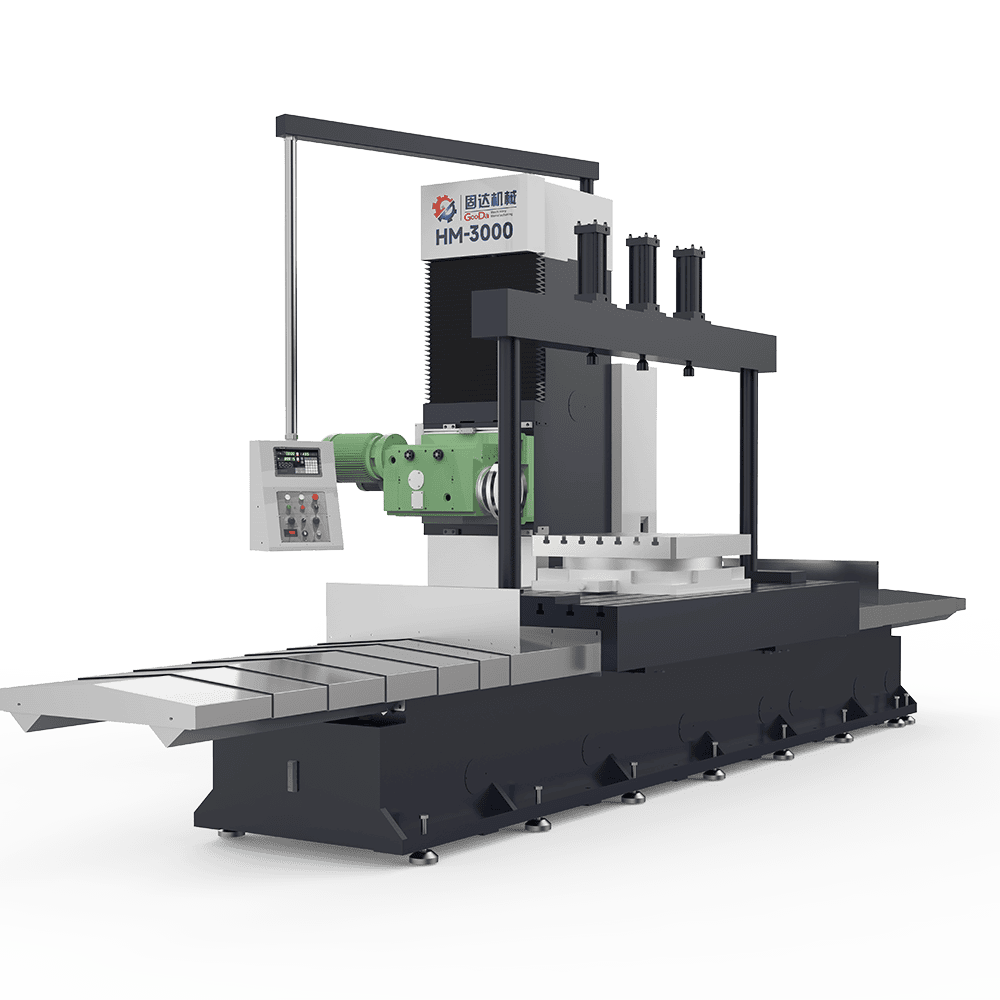

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

Horizontal Boring & Milling Machine Center

Rapid feed rate X/Y/Z/W:10/10/10/5 The machines are mainly used for the processing of large & medium-sized and various basic large parts, like plates, disks, shells, molds and other parts.

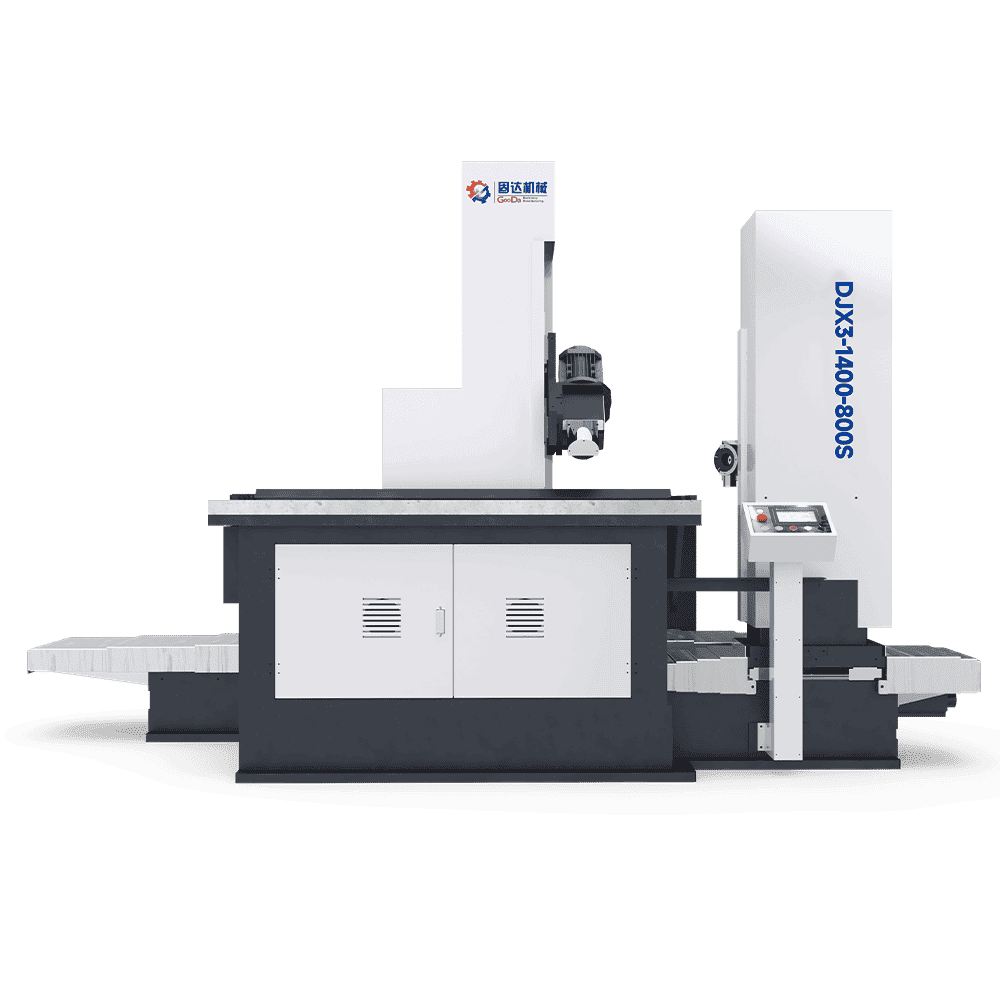

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):1500*900*450mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):2000*1000*450mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):2000*1600*600mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):3000*1600*600mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):2500*1600*600mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):6000*2800*1200mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

CNC Surface Grinding Machine

Processing capacity(Maximum grinding L*W*H):6000*3200*1200mm. CNC Surface grinding machine has a gantry layout as a whole, and the base,columns, and beams form an integral rigid frame structure.

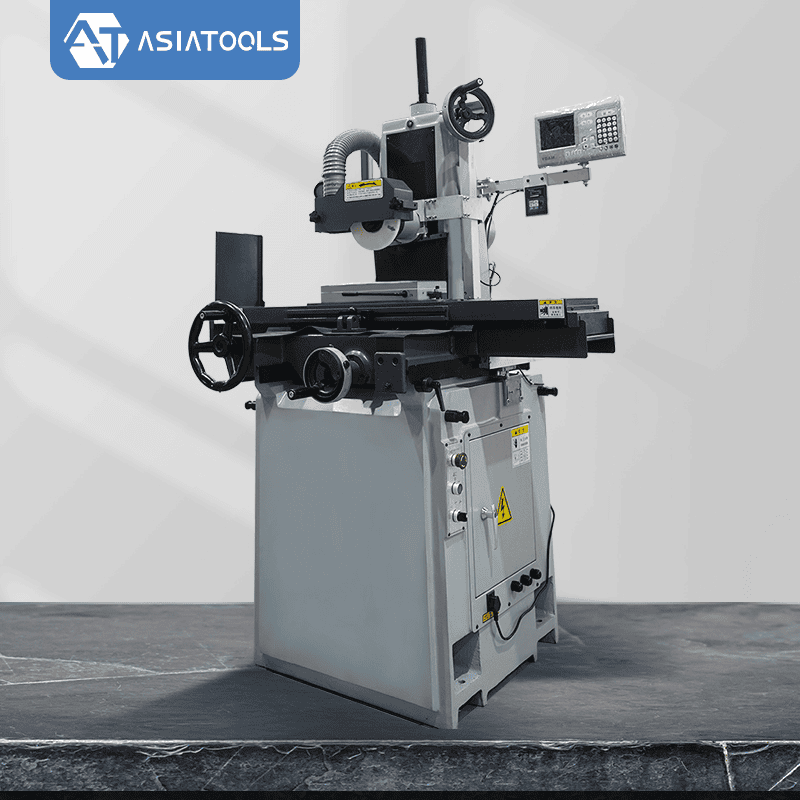

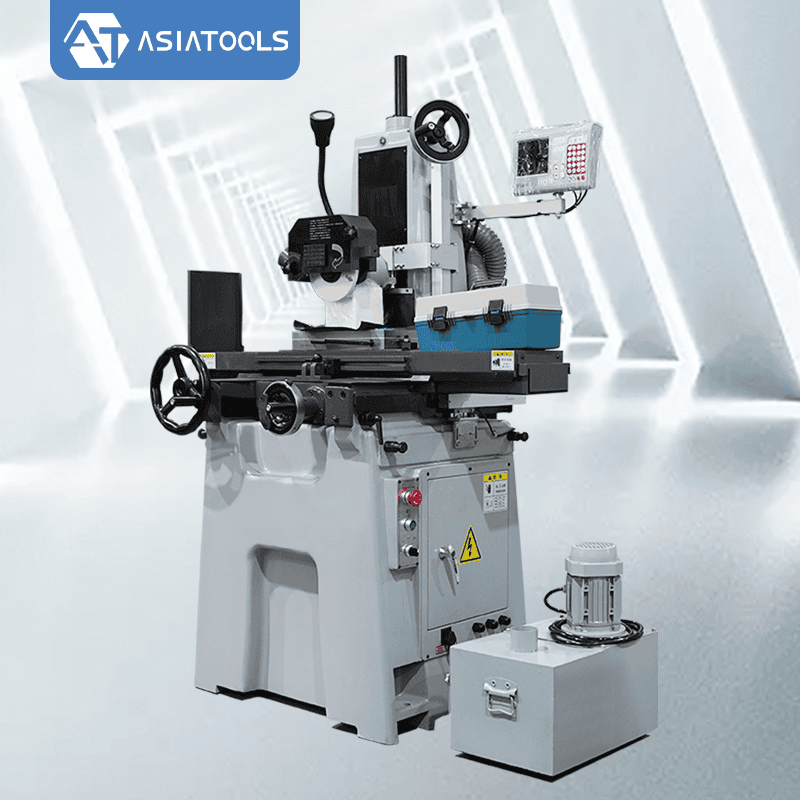

AGM-450G

Max. Table Travel: 475mm The table uses hardened steel linear rails with precision ball bearings for smooth, effortless hand-feeding

AGM-618S

Max. Table Travel: 475mm The table uses hardened steel linear rails with precision ball bearings for smooth, effortless hand-feeding

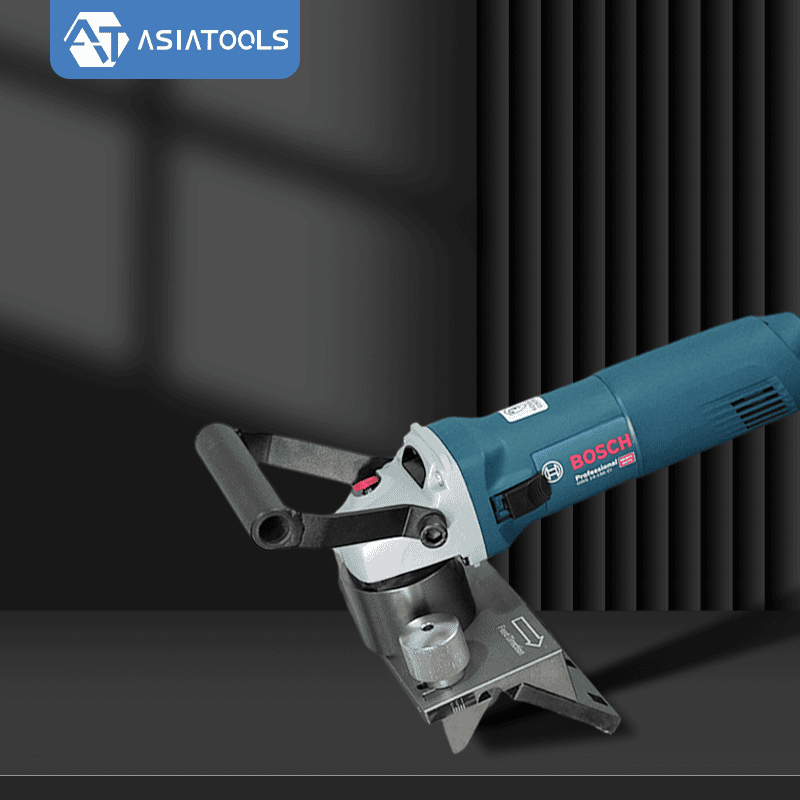

CNC Chamfering Machine

Process capacity:(20-300)*(150-600)*(150-1000)mm It's suitable for metal cutting industriesinvolving mold steel, aluminum, and mold processing.

CNC Surface Grinding Machine

Process capacity:(20-300)*(150-700)*(150-1200)mm It's suitable for metal cutting industriesinvolving mold steel, aluminum, and mold processing.

CNC Surface Grinding Machine

Process capacity:(20-300)*(150-800)*(150-1400)mm It's suitable for metal cutting industriesinvolving mold steel, aluminum, and mold processing.

Compound Chamfering Machine

Rated Power: 750W This machine can chamfer and deburr various materials, such as iron, aluminum, copper, etc.

Compound Chamfering Machine

Rated Power: 750W This machine can chamfer and deburr various materials, such as iron, aluminum, copper, etc.

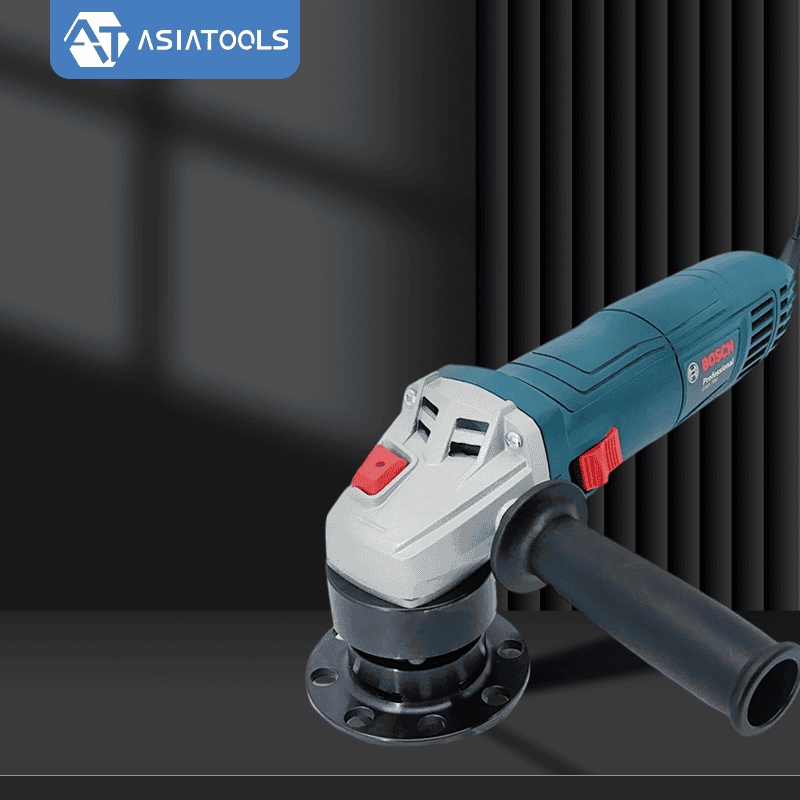

Portable Chamfering Machine

Blade model: AGF-390A Curved edges and round holes chamfering.

Portable Chamfering Machine

Blade model: AGF-390A Straight edge chamfering without guide wheel wear.

Portable Chamfering Machine

Rated Power: 750W This machine can chamfer and deburr various materials, such as iron, aluminum, copper, etc.

Portable Chamfering Machine

Rotating Speed: 12000rmp This handheld chamfering machine features a dual-purpose blade switch, allowing it to process both 45° angles and R angle.

Portable Chamfering Machine

Rotating Speed: 12000rmp The portable machine can process 45° angle with options for chamfering depths of 0–2mm.

Portable Chamfering Machine

Rotating Speed: 12000rmp The portable machine can process 45° angle with options for chamfering depths of 0–2mm.

CNC Circular Saw Cutting Machine

Cutting range square (W*H): 700*100mmmm. Suitable for high-strengthstructural steel, tool steel, alloy steel,For the sawing of wear-resistant steel and other metal sheets.

CNC Circular Saw Cutting Machine

Cutting range square (W*H): 1000*100mmmm. Suitable for high-strengthstructural steel, tool steel, alloy steel,For the sawing of wear-resistant steel and other metal sheets.

CNC Circular Saw Cutting Machine

Cutting range square (W*H): 1600*100mmmm. Suitable for high-strengthstructural steel, tool steel, alloy steel,For the sawing of wear-resistant steel and other metal sheets.

CNC Circular Saw Cutting Machine

Cutting range square (W*H): 2600*100mmmm. Suitable for high-strengthstructural steel, tool steel, alloy steel,For the sawing of wear-resistant steel and other metal sheets.

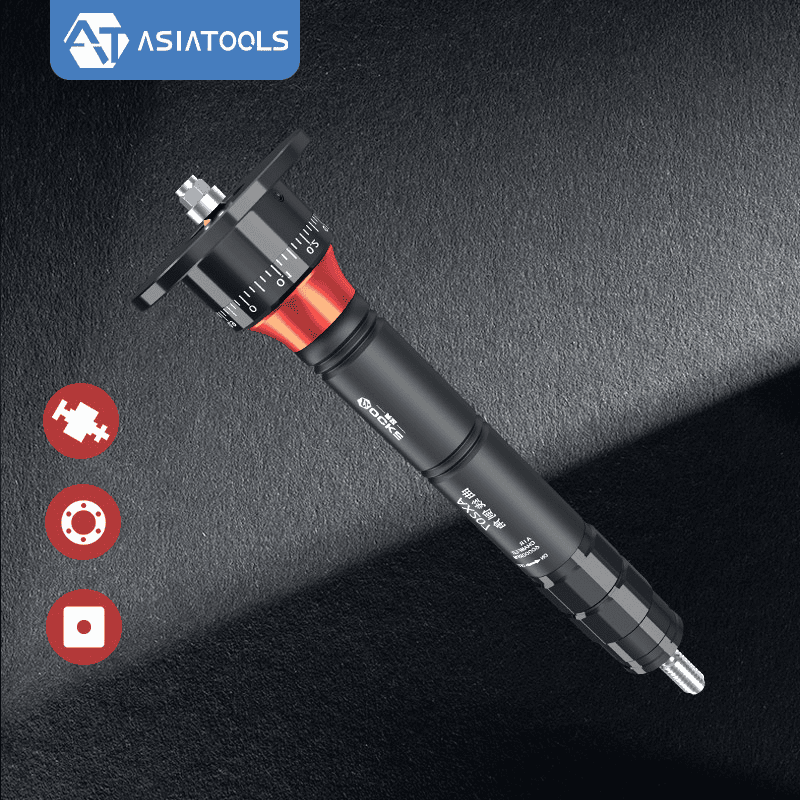

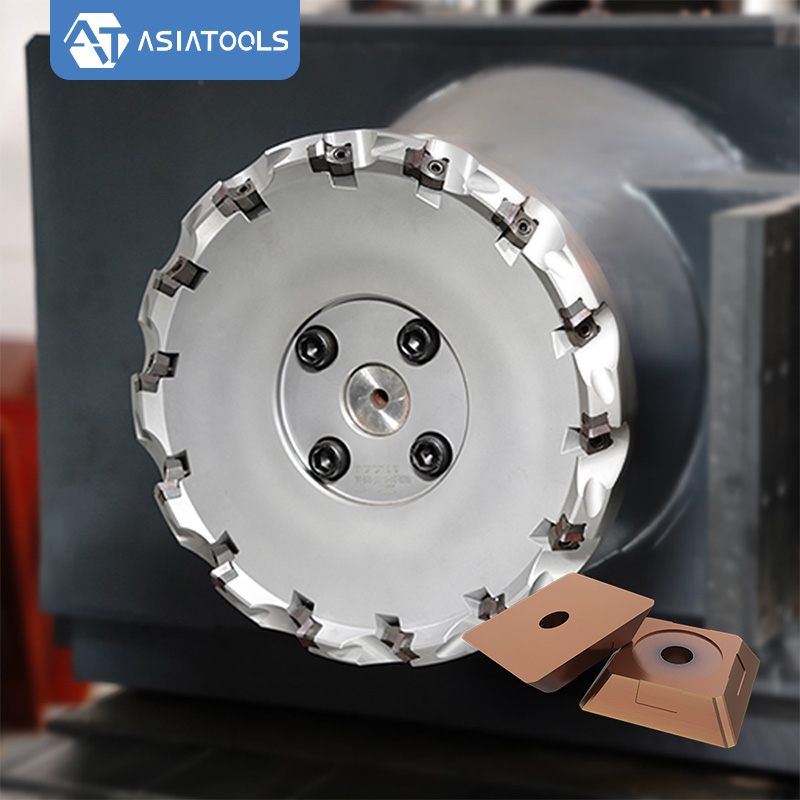

CNC Cutting Tools

Precision-engineered for high performance, our CNC cutting tools ensure clean, accurate cuts for all your machining needs.

Saftey Shoes

Designed for durability and comfort, our safety shoes provide essential protection in demanding work environments.

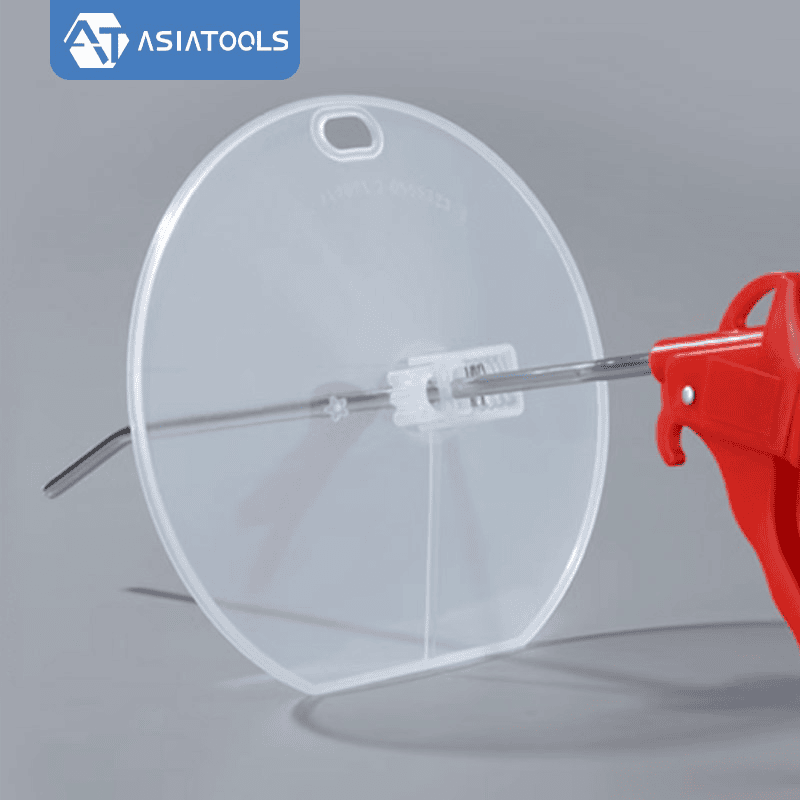

Blow Gun Chip Guarding Shield

Designed for durability and comfort, our safety shoes provide essential protection in demanding work environments.

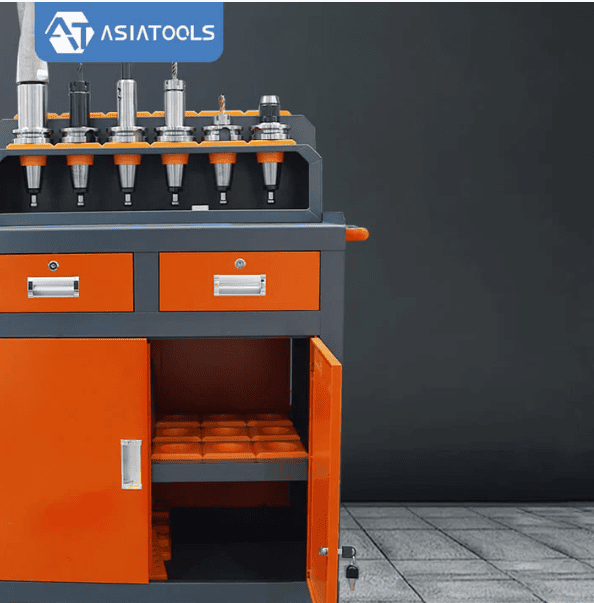

CNC Tool Holder Cart

Our CNC tool holder cart offers convenient, organized storage, and easy mobility for all your essential tools.

CNC Spindle Pull Claw

Ensure secure and efficient tool changes with our robust CNC spindle pull claw.

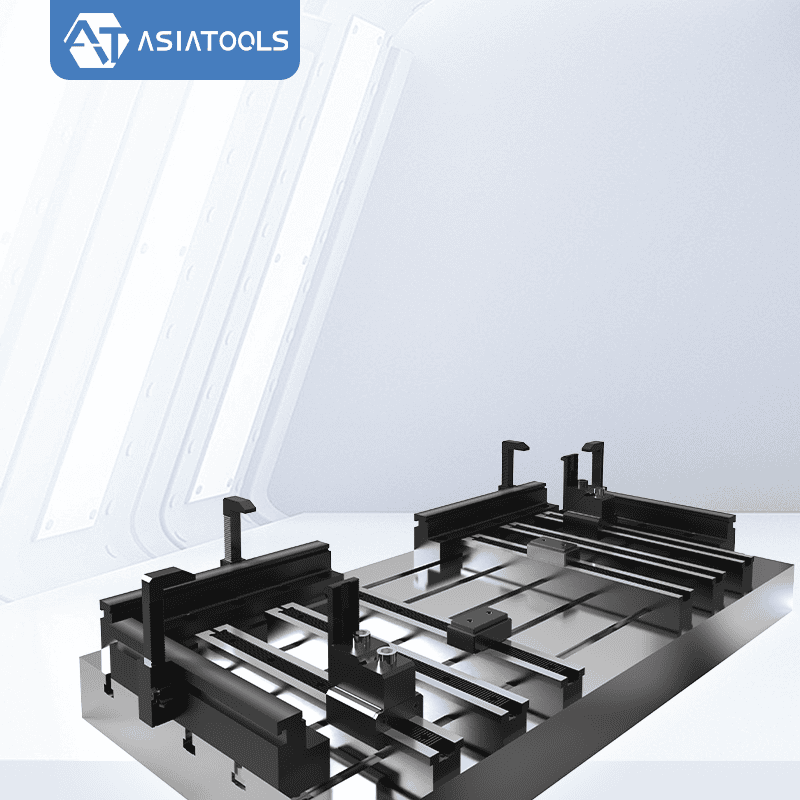

Hydraulic Clamping System

Experience superior workpiece stability and precision with our advanced hydraulic clamping system.

CNC Chip Blower

Maintain a clear and efficient workspace with our CNC chip blower, which effectively removes chips and debris.

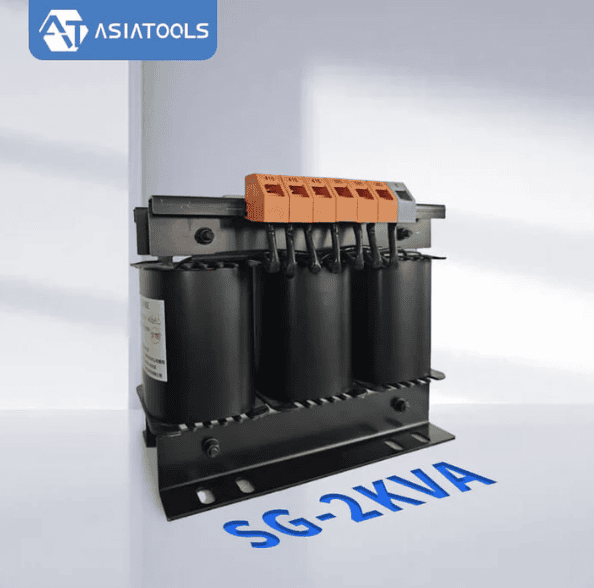

Three Phase Transformer Power Distribution

Deliver reliable and consistent power with our three-phase transformer power distribution system.

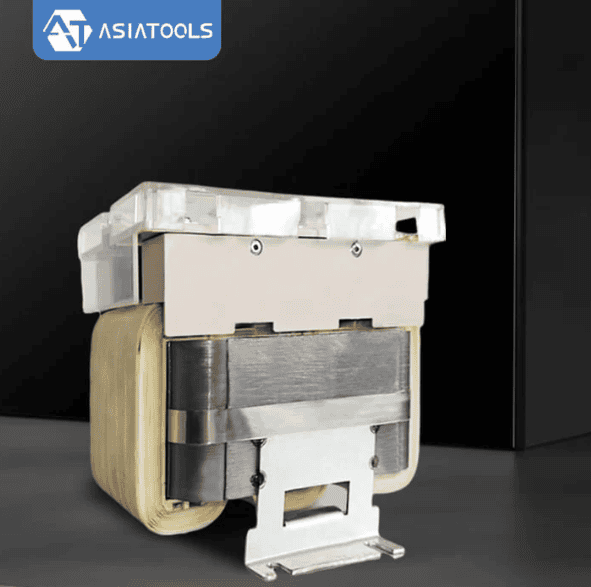

Three Phase Output Line Reactor

Protect your equipment and enhance performance with our three-phase output line reactor, designed to reduce harmonics.

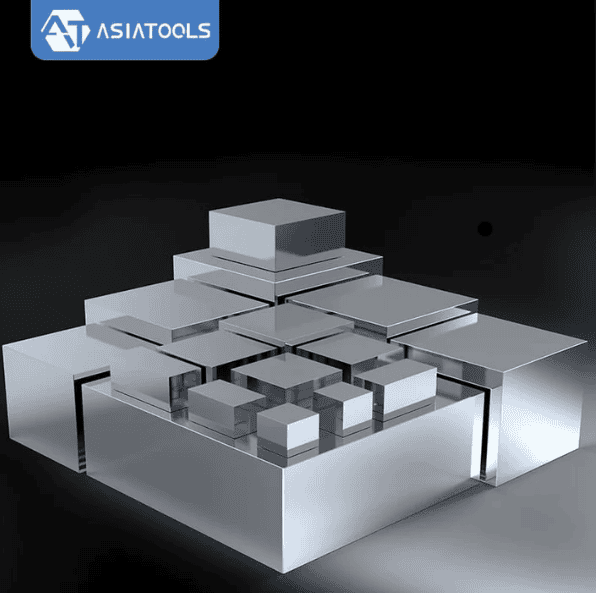

Custom Mold Steel Blocks

Achieve exceptional results with our custom mold steel blocks, tailored to meet your specific design and production requirements.CNC chip blower significantly reduces energy consumption and improves the stability and production capacity of CNC machine tools through high efficiency, intelligent speed regulation, low-noise operation, and easy maintenance. They represent the important breakthroughs of the manufacturing industry in energy conservation, environmental protection, and intelligent production.

With the growing demand for energy conservation and emission reduction in the global industrial field, the CNC chip blower, as an emerging technology, has received widespread attention and application in recent years. This article will introduce in detail its birth background, main functions, classification, product features, and advantages.

The original intention of developing CNC chip blowers stems from the many limitations of traditional CNC machine tool cooling systems. Early cooling devices were not only inefficient but also consumed high energy, which not only increased the company's operating costs but also placed an unnecessary burden on the environment. In addition, with the advancement of precision machining technology, the requirements for temperature control accuracy are getting higher and higher, and the original cooling method can no longer meet the needs of modern production. In this context, a new type of fan that can not only meet the needs of efficient cooling but also significantly reduce energy consumption - the CNC chip blower has emerged.

The core function of the CNC chip blower is to optimize the temperature management inside the CNC machine tool. By precisely controlling airflow distribution, it can effectively remove excess heat generated by the cutting process, thereby maintaining the operation of mechanical components within the ideal operating temperature range. This not only helps prevent equipment damage due to overheating but also improves overall processing accuracy and stability.

Classification by blades

Application types of bladed CNC chip blower in machine tools:

Centrifugal CNC chip blower: This type of fan generates centrifugal force through the rotation of the impeller to push air from the center to the periphery, and is usually used in situations where a large wind pressure is required. In machine tools, centrifugal fans can be used to provide the necessary cooling air flow or used in dust removal systems to help remove dust and debris generated during processing.

Axial flow CNC chip blower: Axial flow fans propel airflow in the axial direction and are suitable for applications that require large flow and low pressure. In the field of machine tools, axial flow fans can be used in heat dissipation systems to help machines maintain appropriate temperatures, or for simple ventilation needs.

Application of bladeless CNC chip blower in machine tools: Bladeless CNC chip blowers, or air multipliers, are a novel design characterized by the absence of any visible blades. This type of CNC chip blower mainly relies on the internal annular gap to inhale air and accelerate the airflow through the annular outlet to form a strong airflow. The advantages of bladeless CNC chip blowers include high safety and easy cleaning due to the lack of blades to accumulate dust. Bladeless CNC chip blower usually has a more modern and simpler appearance design, suitable for environments with certain design requirements.

Product features

High-efficiency design:By advanced aerodynamic principles for optimized design, the air volume is greatly increased while energy consumption is significantly reduced.

Intelligent speed adjustment mechanism::Built-in sensors and controllers can automatically adjust the speed according to actual working conditions to achieve on-demand cooling.

Low-noise operation: By improving the blade shape and material selection, noise generation is effectively reduced, creating a quieter and more comfortable working environment.

Easy to install and maintain: The structure is compact and lightweight, easy to integrate into the existing CNC system, and daily maintenance is simple and convenient.

Significant advantages

Energy saving and emission reduction: Compared with traditional fans, CNC chip blowers can significantly reduce power consumption due to their efficient energy utilization and help enterprises achieve green production goals.

Enhanced reliability: By maintaining a constant operating temperature range, the failure rate caused by thermal stress is greatly reduced, and the overall life and reliability of the equipment are improved.

Promote productivity improvement: Stable temperature control performance allows the machine to maintain high-efficiency operation under a wider range of operating conditions, thereby promoting production capacity increase and quality improvement.

Saving Costs & Energy with ASIATOOLS CNC Chip Blower

CNC chip blower not only represents a breakthrough in energy conservation and environmental protection in the current manufacturing industry but also lays a solid foundation for future intelligent production. As your one-stop solution provider, ASIATOOLS is committed to presenting you with a series of high-quality

CNC chip blowers. Our products can not only reduce energy consumption by up to 80% while ensuring efficiency but also increase wind power by 20%. Combined with the manufacturing of sturdy and durable materials, our products ensure long-term and reliable operation of the equipment. ASIATOOLS's CNC chip blower is designed with an extra-large air outlet and a bladeless design, which reduces energy consumption while ensuring safety. It is also easy and quick to operate, plug, and play, which greatly facilitates the user's installation and usage experience.