Steel for Mold Plates with Free Machining Service

Trusted by mold makers woldwide for over 12 years.

Complete and Reliable Supply Chain: we have abundant raw material resources at competitive prices.

Samples available: We can provide samples for your testing and evaluation before bulk orders.

Custom Dimensions: we can customize dimensions to your exact needs—from large to small blocks.

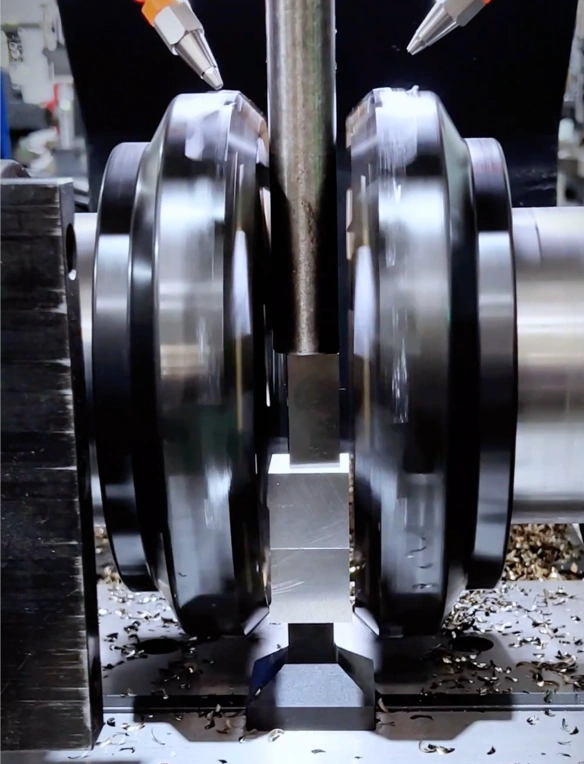

Full Machining Service: More importantly, with our own advanced machines, we go beyond material supply to provide full machining services, including milling, grinding, drilling, and precision CNC part processing.

Dedicated Support: Our service team is always ready to assist and provide solutions to your specific needs.Contact us today.

At ASIATOOLS, we are equipped with electric arc furnace and induction furnace designed to handle demanding industrial applications. Our large-capacity Furnaces enable us to process wide range of high-performance steel materials.

Lower Unit Cost for Large Orders

Shorter Lead Times for Large Components

Custom Production Flexibility

We offer different types of mold steel—#45, P20, 718, H13, S136, and 12CrMo—they are widely used in plastic mold manufacturing(For other mold steel material, feel free to contact us). Each material offers unique properties to meet various mold requirements. See the comparison below for key performance differences:

Suitable for high-strength structural steel, stable performance, and precision. CP-26010PRO numerical control high-speed circular saw using carbide saw blade cutting, suitable for high-strength structural steel, tool steel, and alloy steel. The machine has reasonable structure, stable performance, and high precision.

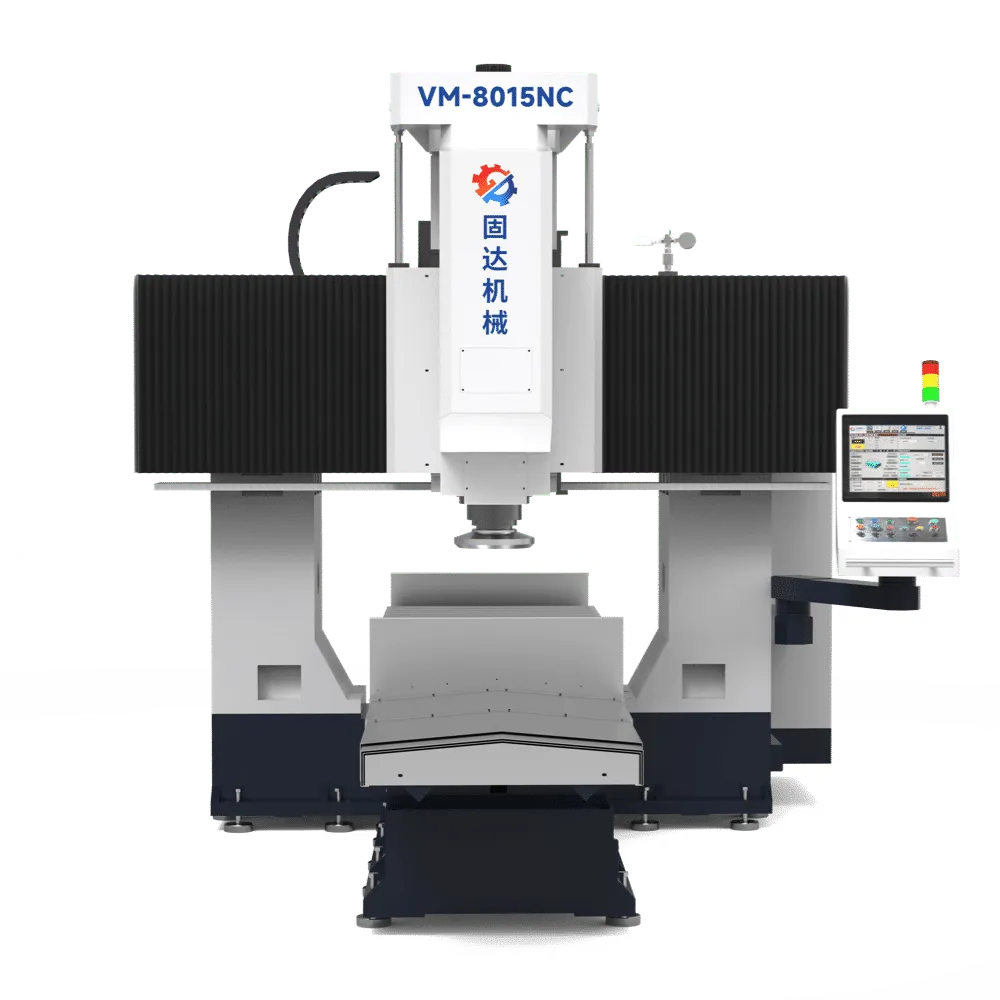

CNC vertical milling machine with a double worktable can clamp and process simultaneously. Its efficiency is over 4 times that of traditional machines.

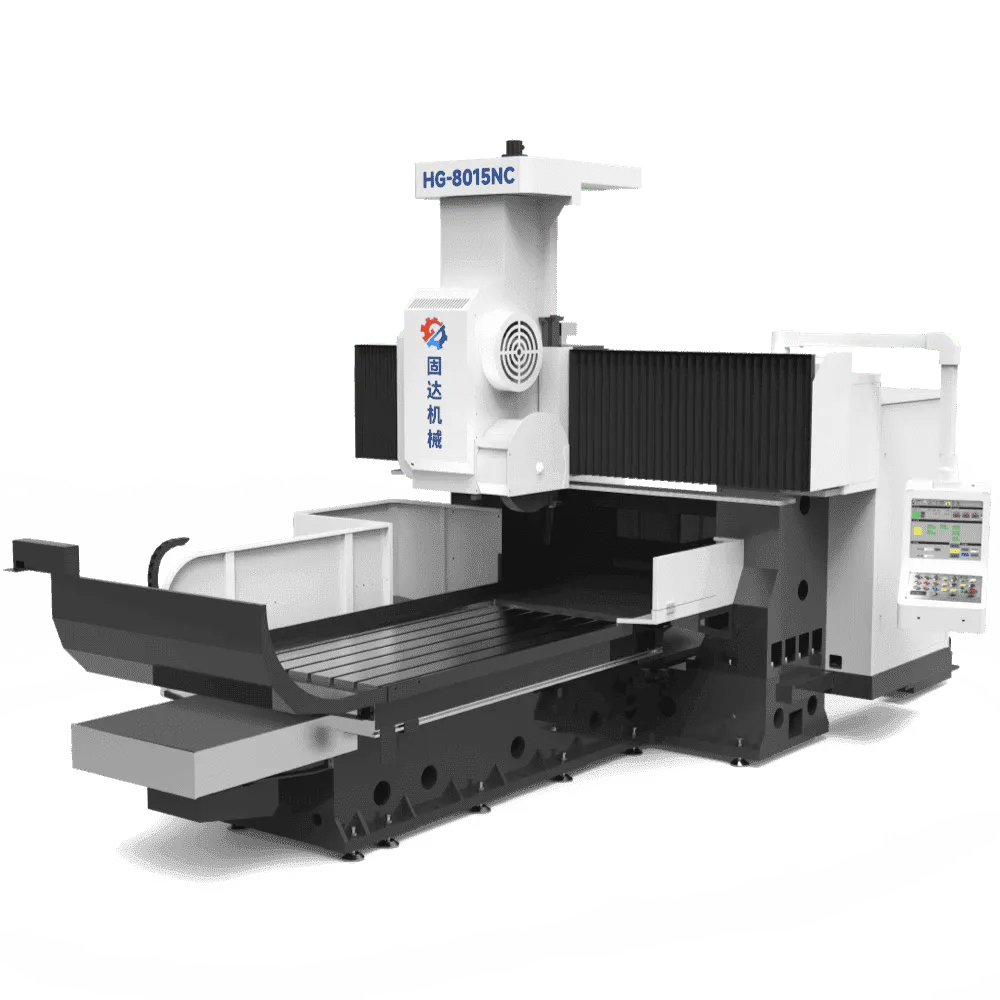

Belt-type spindle driving, suitable for fine cutting needs, with high efficiency and excellent performance! Machining size: L1500xW800xH350/450mm. Distance between columns: 1300mm.

The machine system is optional, one click starts automatic precision milling of 4 surfaces; Efficient and high-precision, occupying a small area in the job shop; a small material processing tool!

The machine is equipped with double milling heads, with 2nd transmission and rotary table. With optional servo plates with precise reference positioning, the machine is convenient and efficient to operate with excellent cutting performance!

The CNC gantry grinding machine has a gantry layout as a whole, and the base, columns, and beams form an integral rigid frame structure. The structural design ensures the accuracy and performance of the machine. lt is composed of gantry frame, base, grinding head oil supply and transmission system, table transmission, lubrication system, cooling system,hydraulic control system and electrical system.

We supply mold modules ranging from large sizes (up to 2800*1400*800mm)

to small precision blocks (as small as 7*7*7mm)—all

with Level-2 ultrasonic testing guaranteed.

| Thickness | 6 | 8 | 10 | 12 | 14 | 15 | 16 | 18 | 20 | 22 | 25 | 28 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 |

| Width | 15 | 15 | 15 | 15 | 15 | 15 | ||||||||||||||||

| 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |||||||||||||

| 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | ||||||||||||

| 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||||||||||

| 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | ||||||||

| 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |||||||

| 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | ||||||

| 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |||||

| 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | ||||

| 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |||

| 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | ||

| 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | |

| 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | |

| 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | |

| 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | |

| 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | |

| 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | |

| 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | 115 | |

| 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | |

| 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | |||||

| 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | |||||

| 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | |||||

| 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | |||||

| 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | |||||

| 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |||||

| 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | ||||||||||

| 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | ||||||||||

| 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | ||||||||||

| 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | ||||||||||

| 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | ||||||||||

| 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | ||||||||||

| 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | ||||||||||

| 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | ||||||||||

| 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | ||||||||||

| 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | ||||||||||

| 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |||||||||||||||

| 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | |||||||||||||||

| 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |||||||||||||||

| 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | |||||||||||||||

| 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

When you order our mold steel, machining is included free of charge. Backed by our self-manufactured CNC machines, we offer reliable and cost-effective processing for every steel block we deliver.

To explore more, visit our MOLD AND DIE Service Page or Contact Us for personalized consultation and processing solutions.

We understand that mold construction is complex and involves more than just the processing of large modules, mold frames, and bases. It also requires precision parts such as mold inserts, ejection pins, locating rings, slides, and more. To meet these needs, we offer small precision machining services as well as custom component machining for the mold industry. For more details, visit our Precision Machining Service page to upload your part files, or contact us directly for personalized, one-on-one support.

12+ Years of Experience

12+ Years of Experience

Large Inventory Ready

Large Inventory Ready

Free Machining Service

Free Machining Service

Full-size & Small Part Capabilities

Full-size & Small Part Capabilities

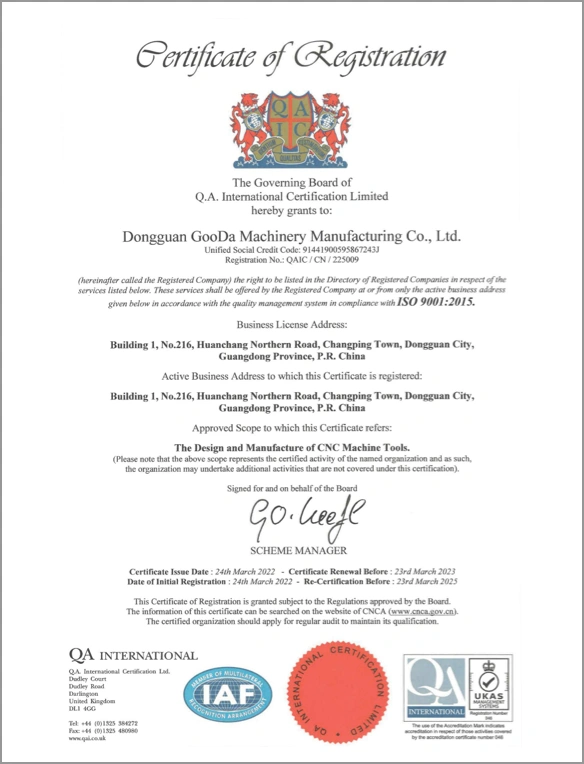

ISO Quality Standards

ISO Quality Standards

Fast Turnaround Time

Fast Turnaround Time