In the mold manufacturing industry, the choice of mold steel material is crucial. This decision affects not only the product’s appearance and precision but also its production efficiency and lifespan. In recent years, stainless steel molds have been widely used in various high-end manufacturing fields due to their excellent corrosion resistance, wear resistance, and ease of maintenance. This article will focus on the advantages, applications, and maintenance methods of stainless steel molds.

1. Structural Differences

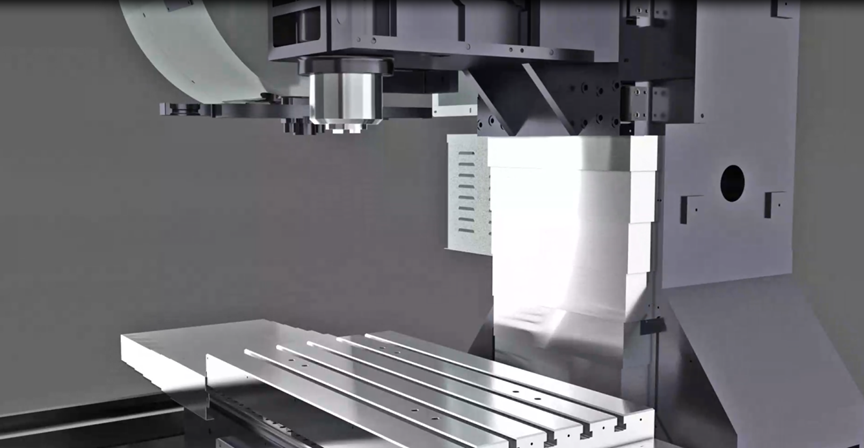

In a horizontal machining center (HMC), the spindle is positioned horizontally, while the Z-axis moves front-to-back during machining.

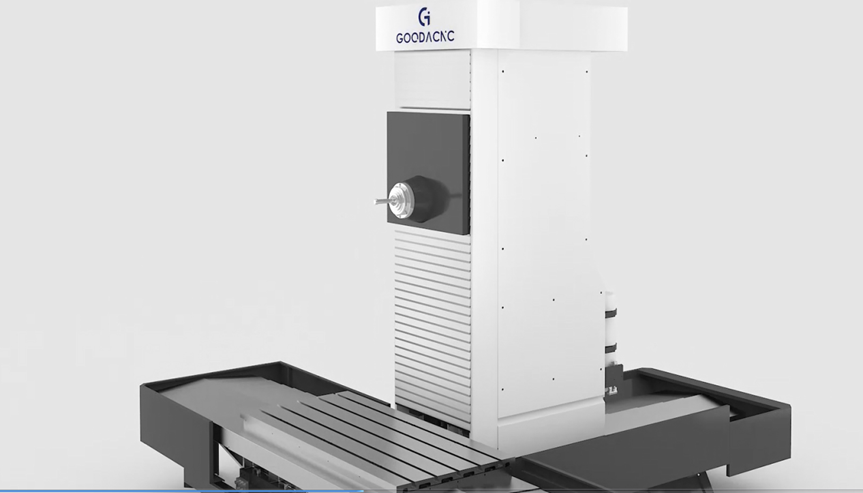

In a vertical machining center (VMC), the spindle is oriented vertically, and the Z-axis moves up and down during cutting.

Additionally, HMCs have better chip evacuation since gravity helps remove chips away from the cutting area, improving surface quality and reducing tool wear.

2. Worktable Differences

Due to their vertical spindle orientation, VMCs are ideal for taller workpieces and precise surface machining. Their compact structure and small footprint make them suitable for small and medium-sized workshops.

The horizontal spindle orientation allows HMCs to handle greater cutting forces and support heavier workpieces. HMCs are often equipped with rotary tables or dual pallets, enabling multi-face machining in a single setup. This significantly reduces downtime caused by part repositioning and increases throughput. Therefore, horizontal machining centers have a clear advantage when machining large, heavy, or complex workpieces.

3. Machining Efficiency Differences

For smaller or vertically oriented parts, VMCs often achieve shorter tool paths and faster cycle times.

When machining large workpieces, horizontal machining centers, due to their greater load-bearing capacity and cutting stability, can achieve higher cutting speeds and deeper cutting depths, thereby improving machining efficiency. In general, VMCs are preferred for high-precision, low-volume parts, while HMCs are better suited for mass production or heavy-duty cutting operations.

4. Summary

Both vertical and horizontal machining centers have their own characteristics and advantages. When choosing between them, consider factors such as the size, weight, shape, and machining requirements of the workpiece.