1、 Clarify the application direction:

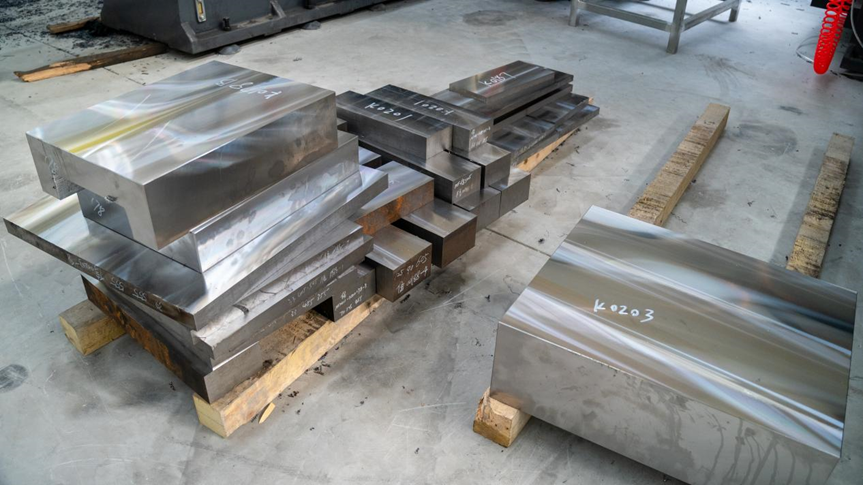

First, we need to understand the actual classification of mold steel. According to international standards and industry practices, mold steel can be broadly divided into the following categories:

1. Cold Work Die Steel:

Used in processes such as cold stamping, cold extrusion, drawing, shearing, and coining. Common materials include Cr12MoV, D2, and SKD11.

2. Hot Work Die Steel:

Used in hot forging, hot extrusion, die casting, and forging dies. Characterized by high-temperature strength, toughness, and thermal fatigue resistance. Common materials include H13, 5CrNiMo, and 3Cr2W8V.

3. Plastic Mold Steel:

Used in injection and blow molds. Characterized by excellent polishing properties, corrosion resistance, and processability. Common materials include P20, 718, NAK80, and S136.

This article uses the examples of plastic mold steel and hot work mold steel to illustrate that determining the intended application of the mold steel is crucial when selecting mold steel:

(1) Plastic Mold Steel: Commonly used in injection molds, particularly for the production of large quantities of plastic parts. This type of steel typically possesses sufficient polishing properties and wear resistance, ensuring a smooth surface finish. It also exhibits excellent thermal stability, resisting deformation during continuous production. It is commonly used in industries such as appliance housings, transparent products, and food packaging.

(2) Hot Work Die Steel: Primarily used in high-temperature applications such as hot forging, die casting, and extrusion. Because these molds must withstand prolonged high temperatures and severe impact, they require excellent hot strength, toughness, and thermal fatigue resistance. Typical applications include automotive engine parts, aircraft structural components, and die casting molds.

2、Balancing Cost and Performance

Many users tend to focus solely on price when selecting steel, but the full life-cycle of the steel should be considered. While higher-grade mold steel may be more expensive to purchase, it offers a longer lifespan and improved wear resistance, ultimately saving on maintenance and replacement costs. For example, using plastic mold steel with improved corrosion resistance can prevent rust caused by condensation or ambient humidity, significantly reducing the risk of downtime for repairs.

3、Focus on Machinability and Heat Treatment

During mold manufacturing, machinability can directly impact delivery cycles. If the mold requires multiple revisions or complex machining, the steel's machinability and heat treatment stability are particularly important. Highly machinable steel can shorten manufacturing cycles. Steel with minimal heat treatment deformation ensures mold precision and dimensional stability. This not only saves time for mold manufacturers but also reduces the risk of rework.

4、Consider Surface Finish and Corrosion Resistance

For molds for transparent parts or food-grade plastics, surface finish requirements are extremely high, so steel that can withstand a high level of polishing is essential. Furthermore, if the mold's operating environment is subject to moisture, cooling water, or corrosive gases, mold steel with high corrosion resistance is advantageous. For example, some stainless plastic mold steels can effectively extend mold life, thereby ensuring product quality.

Summary

Selecting mold steel isn't just a technical issue; it's a strategic one that impacts a company's profitability and competitive advantage. By clearly defining application requirements, rationally evaluating cost and performance, and focusing on processing characteristics and corrosion resistance, manufacturers can significantly improve mold life and production efficiency. Whether selecting plastic mold steel or forging mold steel, intelligent selection will deliver greater value. To learn more about our steel solutions and services, explore our steel database or contact us for more information.