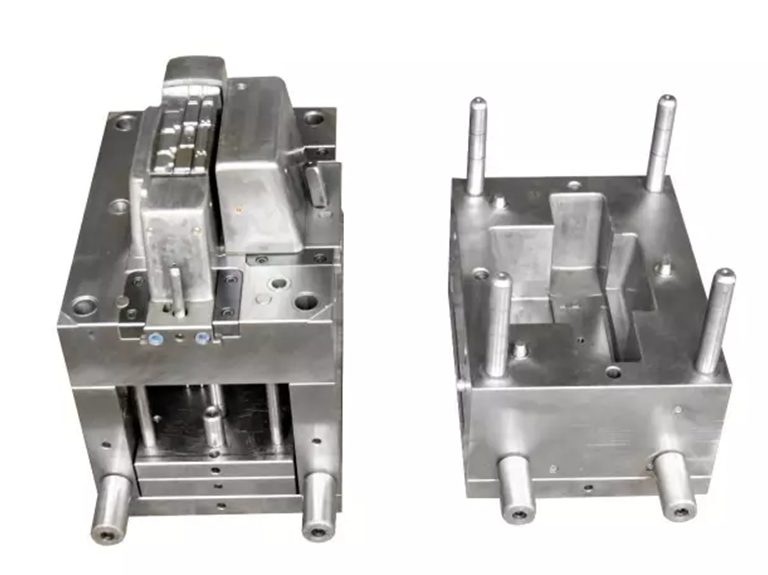

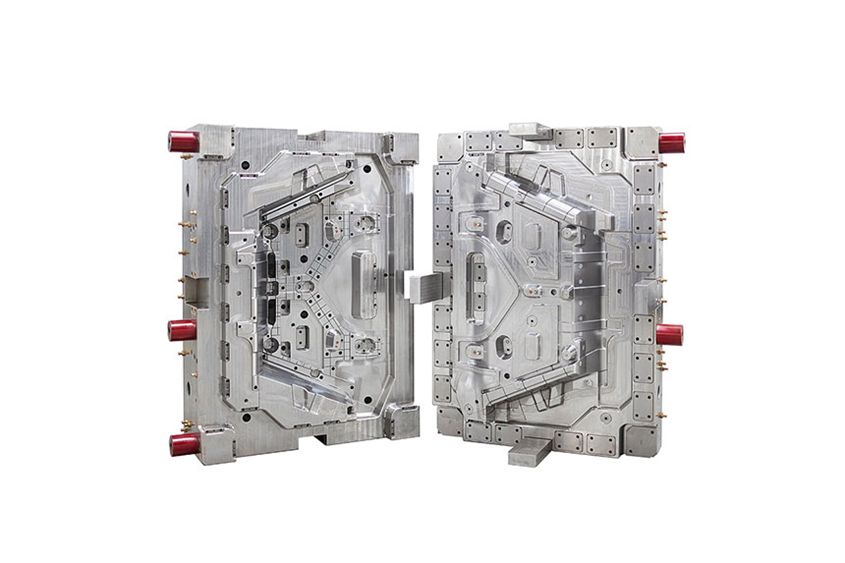

In the mold manufacturing industry, the choice of mold steel material is crucial. This decision affects not only the product’s appearance and precision but also its production efficiency and lifespan. In recent years, stainless steel molds have been widely used in various high-end manufacturing fields due to their excellent corrosion resistance, wear resistance, and ease of maintenance. This article will focus on the advantages, applications, and maintenance methods of stainless steel molds.

1. Advantages of Stainless Steel Molds

(1) Strong Corrosion Resistance

Conventional mold steels are prone to rusting in humid or acidic or alkaline environments, affecting the mold surface quality. Stainless steel molds, however, due to their high chromium content, effectively resist rust and corrosion, maintaining a long lifespan even in injection molding environments involving chlorine-containing plastics or those requiring the addition of flame retardants.

(2) High Hardness and Wear Resistance

Through appropriate heat treatment, stainless steel molds not only maintain high hardness but also possess excellent toughness. This makes them less susceptible to cracking or deformation under high-intensity and high-pressure conditions, making them ideal for long-term or high-volume production.

(3) Excellent Surface Finish

Precision polishing of stainless steel mold surfaces achieves a higher gloss and surface quality, making them suitable for precision mold manufacturing. This offers significant advantages for products requiring transparency or a high level of aesthetic appeal, such as medical device housings and optical components.

2.Typical Applications of Stainless Steel Molds

(1) Medical Industry: Medical devices and disposable consumables require stringent hygiene standards, making stainless steel molds the preferred choice due to their corrosion resistance and easy cleaning properties.

(2) Food Packaging: Food-grade plastics place extremely high demands on mold safety, and stainless steel molds ensure pollution-free production. 304 stainless steel is often used in food contact tools due to its corrosion resistance, high temperature resistance, and rust resistance.

(3) Chemical and Specialty Plastics: For plastics with chlorine, glass fiber, or other corrosive additives, stainless steel molds last significantly longer than conventional mold steels.

3. Key Points for Stainless Steel Mold Maintenance

(1). Rust Prevention: Spray rust inhibitor or apply protective oil to prevent oxidation. Store in a dry and ventilated location to avoid stacking and bumping.

(2). Daily Cleaning and Lubrication: Immediately remove waste, oil, and iron filings from the mold cavity after use to keep it clean. Apply appropriate oil to sliding surfaces to reduce friction and wear.

(3). Surface Enhancement: Surface treatments such as nitriding and chrome plating improve wear resistance.

(4). Storage Environment Control: Maintain a dry environment when not in use. Rust inhibitors may be added.

4. Summary

In summary, stainless steel molds, thanks to their excellent corrosion resistance, wear resistance, and surface quality, have become a key choice in high-end manufacturing. While the initial investment is relatively high, with proper maintenance, their longevity and stability can deliver significant long-term economic benefits. If your industry places high demands on mold life, product appearance, or sanitation, choosing stainless steel molds is a wise investment. To learn more about our steel solutions and services, explore our steel database or contact us for more information.